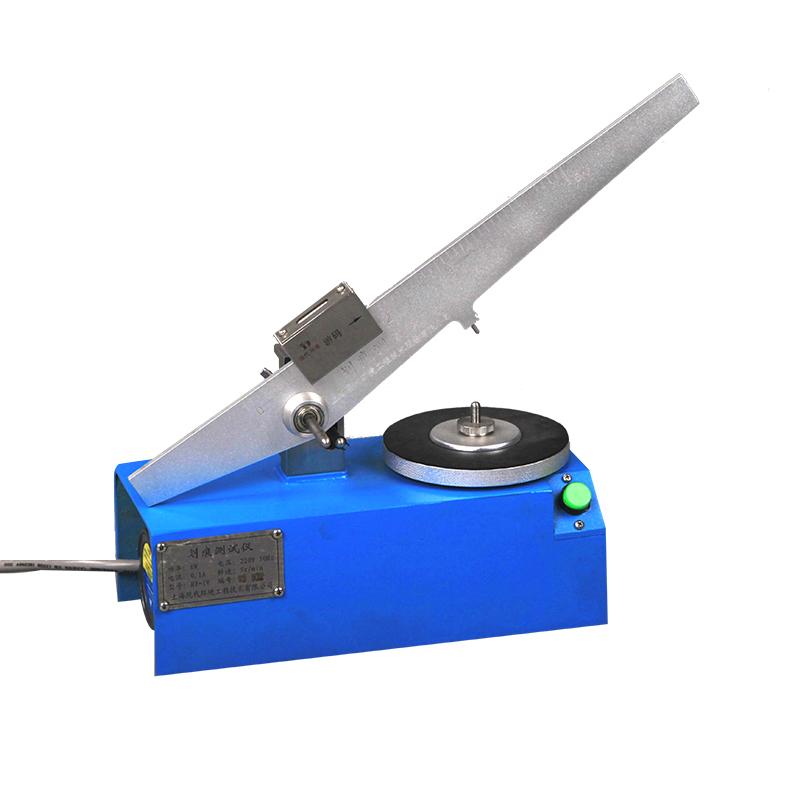

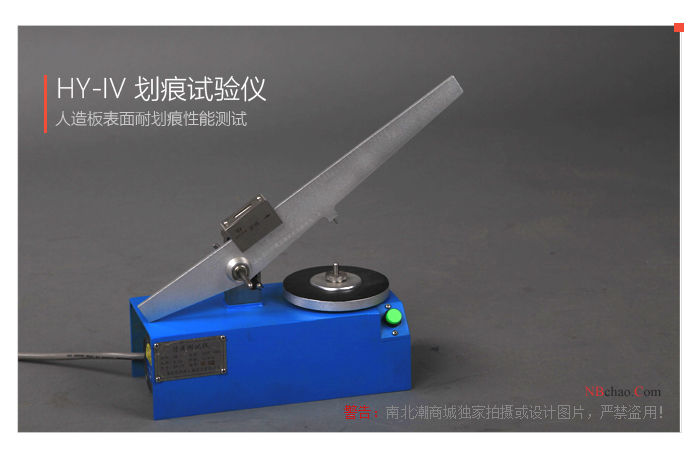

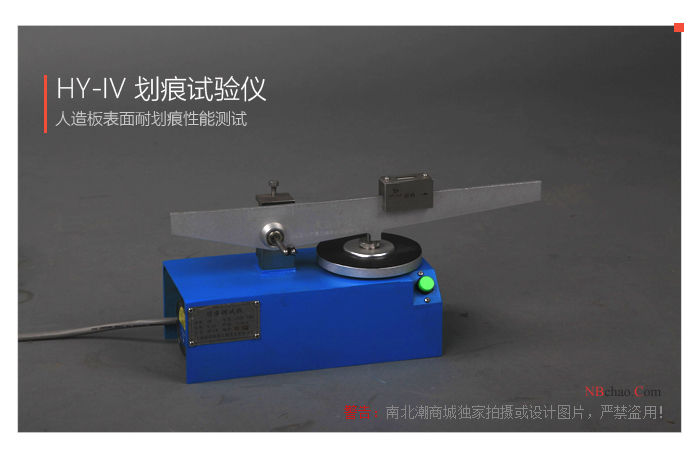

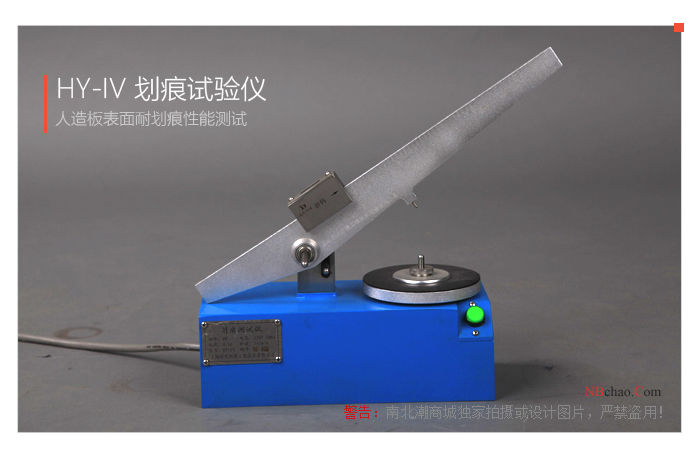

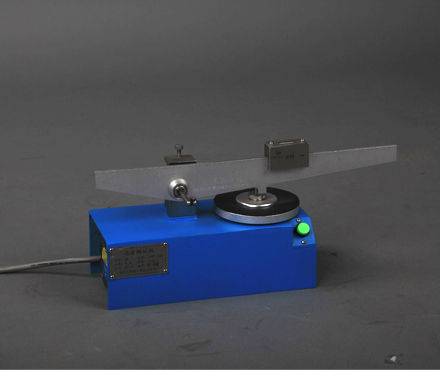

MODERNER HY-IV scratch test instrument, suitable for testing the scratch performance of various wood-based panels and veneer wood-based panels

Moderner HY-Ⅳ Scratch meterSPEC

Moderner HY-Ⅳ Scratch meterDetails

Moderner HY-Ⅳ Scratch meterPacking list

- SKU

- NB000725

- Load (loading) range

- 0~10N

- Rotation speed of turntable

- 5rpm

- Maximum size of test sample

- 100*100mm

- Maximum thickness of test sample

- 10mm

- Motor Power

- 6W

- meet the standard

- GB/T15102、GB/T17657

- Power

- 220V AC 50Hz

- Dimensions

- 430*230*200mm

- Instrument Weight

- 4.5kg

- Calibrated Certificate

- without

Overview of HY-IV scratch Tester

MODERNERThe HY-IV scratch Tester is a scratch test instrument and equipment that tests the scratch resistance of the surface of various artificial panels and decorative artificial panels. The HY-IV scratch Tester adopts a large speed ratio and large output torque gear reduction box. This ensures that the turntable rotation speed is constant under different test loads, so that the test results have higher accuracy.The test load of the HY-IV scratch Tester is 0~10N, and the motor power is 6W.

This HY-IV scratch Tester is carefully designed and manufactured in MODERNERs in accordance with the relevant provisions of GB/T15102 "Impregnated Adhesive Film Paper Decorated Artificial Panels" and GB/T17657 "Test Methods for Physical and Chemical Properties of Artificial Panels and Decorated Artificial Panels" . MODERNERAll parts of the HY-IV scratch Tester are installed in a wooden box with a handle. It has the characteristics of compact structure, small appearance and easy portability.

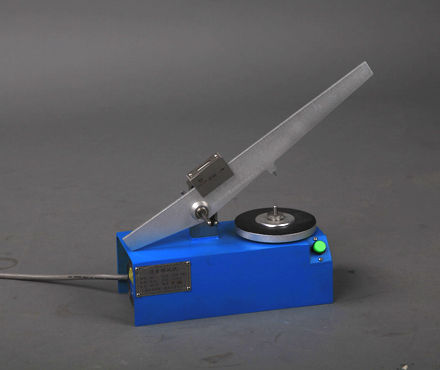

Actual pictures of HY-IV scratch Tester

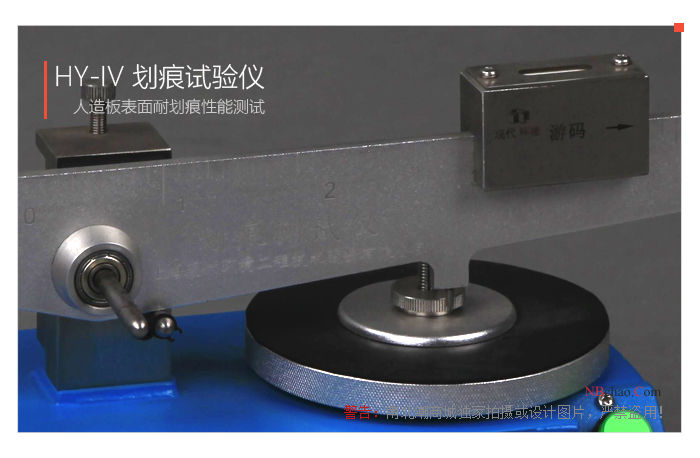

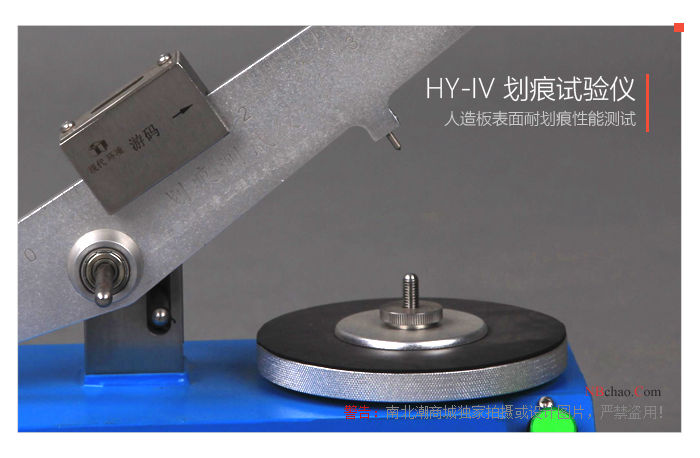

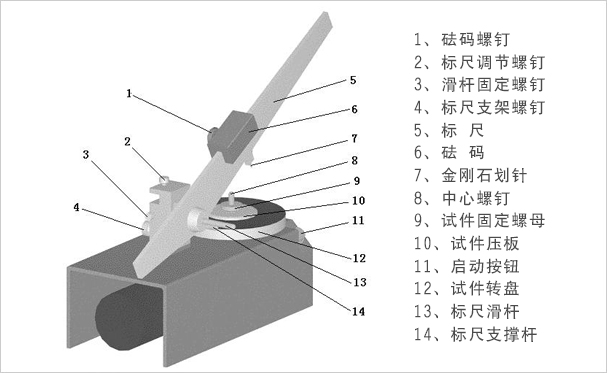

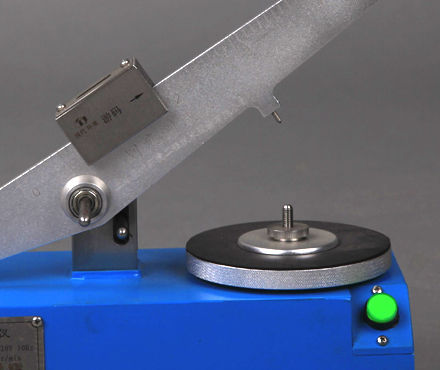

The main structure

The scratch Tester uses the lever principle. When the upper edge of the scale is in a horizontal position, moving the weight above the scale to different scale values ââcan make the force of the tip of the diamond scratcher on the surface of the tested plate consistent with the scale value. The scale rotating shaft is supported by ball bearings, which rotates flexibly and reduces the friction moment, so that the pressure exerted on the tip of the diamond scribe needle has good repeatability, which ensures good repeatability of the test results.

Steps

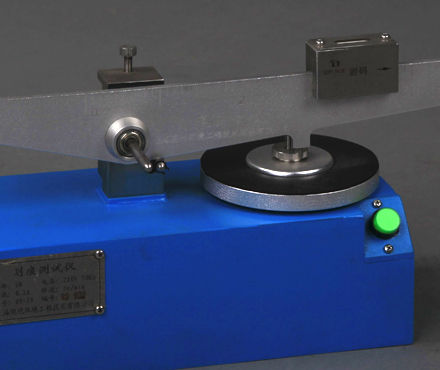

1. Preparation work before the test: (see Figure 1)

â´ willThe HY-IV scratch Tester is placed on a stable, flat test platform, with the operator facingHY-IV scratch Tester , then turn onThe wooden box of the HY-IV scratch Tester .

âµ Loosen the slide rod fixing screw; take out the scale slide rod (with scale) and scale support rod (without scale) from the accessory box, and insert them into the holes on the left and right sides of the scale bracket respectively (the flat end of the scale slide rod is inserted into the hole ); when the entire circle of engraved lines at the end of the scale slide rod is just exposed from behind the scale bracket, tighten the slide rod fixing screw to fix the scale slide rod, and the scale support rod can slide freely in the hole.

ⶠRemove the scale from the scale holder, face the operator with the graduated side, align the bearing hole in the middle of the scale with the scale slide rod, and insert it into the hole.

â· Lift the right end of the ruler, pull out the ruler support rod, and lower the ruler so that the ruler rests on the ruler support rod.

⸠Take out the diamond scribe needle, insert it into the hole in the center of the protrusion in the middle of the ruler, and fix it with the set screw on the right side.

â¹ Insert the power plug into the power socket on the wall and turn on the power.

2. Run:

â´ Process the plate to be measured to the size specified by the standard (the thickness shall not exceed 10mm), and drill a ï7mm hole in its center.

âµ Unscrew the fixing nut of the test piece, remove the test piece pressure plate, place the processed plate to be tested with the tested side upward on the test piece turntable, insert the center hole into the center screw, put the test piece pressure plate on, and tighten the test piece Fixing nut.

ⶠPush in the scale support rod, lower the scale, and make the tip of the diamond scribe needle touch the surface of the plate to be measured.

â· Loosen the scale bracket screw.

⸠Turn the scale adjustment screw to adjust the scale to the horizontal position. (observeThe level on the upper end of the weight of the HY-IV scratch Tester is such that the bubble reaches between the two scribed lines in the center, and the scale is in a horizontal position. )

â¹ Tighten the scale bracket screw.

⺠Loosen the weight screw, move the weight to the required load scale* (align the right edge of the weight with the scale), and tighten the weight screw.

â» Press the start button and hold it for 2 seconds. The test piece turntable starts to rotate and stops after one rotation. Remove the test piece and observe the scratches on the surface of the test piece.

â¼ After all tests are completed, removePut the parts of the HY-IV scratch Tester back to their original places, and close the lid of the wooden box to protect the cleanliness of the instrument.

Provisions on scratch Testers in national standard GB/T 15102-94

6.3.10 Surface scratch resistance test method

6.3.10.1 Principle

The surface scratch resistance is to test the ability of the surface decoration layer of the product to withstand the diamond needle scratching the surface under a certain force.

6.3.10.2 Instruments

Scratch Tester. (picture omitted)

6.3.10.3 The test piece shall be prepared according to the provisions of 6.3.1. (The length and width of the test piece are specified to be 100mm)

6.3.10.4 Test procedures

6.3.10.4.1 Wipe the surface of the test piece clean, and fix the tested surface upward on the stage of the scratch Tester. Adjust the height of the beam so that when the tip of the diamond needle contacts the surface of the specimen, the upper edge of the beam is in a horizontal position.

6.3.10.4.2 Move the weight to the 1.5N position, start the rotation of the stage, and make the diamond needle mark one circle on the surface of the specimen.

6.3.10.4.3 Remove the test piece and observe the condition of the scored part of the test piece.

6.3.10.5 Result presentation

Observe from any angle at a distance of about 40cm from the surface of the test piece whether there is a full circle of continuous scratches on the scored part of the surface of each test piece.

6.3.10.6 Result Judgment

The three test pieces can be judged as qualified only if there are no continuous scratches in the entire circle.

- 1ISO FDIS 1518-2010《Paints and varnishes. Scratch test》

- 2 1518-2010《Paints and varnishes. Scratch test》

- 3ISO 12137-2011《Paints and varnishes Determination of mar resistance》

- 4GB/T 17657-2013《Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels》

- 5ISO 1518-1992《Paints and varnish scratch test》

HY-Ⅳ

HY-Ⅳ