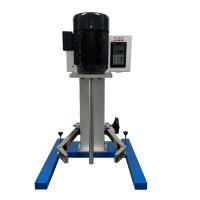

MODERNER WJ-2.2D Variable Speed Stirrer (Brushless DC Type, Electric Lift) Disperse, Harmonize, Stir for various liquid materials

SEModerner WJ-2.2D Variable Speed StirrerSPEC

Moderner WJ-2.2D Variable Speed StirrerDetails

Moderner WJ-2.2D Variable Speed StirrerPacking list

- SKU

- NB000728

- Power

- 220V 50Hz/60Hz

- power

- 2200W

- Speed range

- 300~4000rpm

- Impeller configuration

- F120mm

- Lifting stroke

- 400mm

- Overall Dimensions

- 500*580*850mm

- Total Weight

- 45kg

- Bolt diameter

- 8mm

Introduction

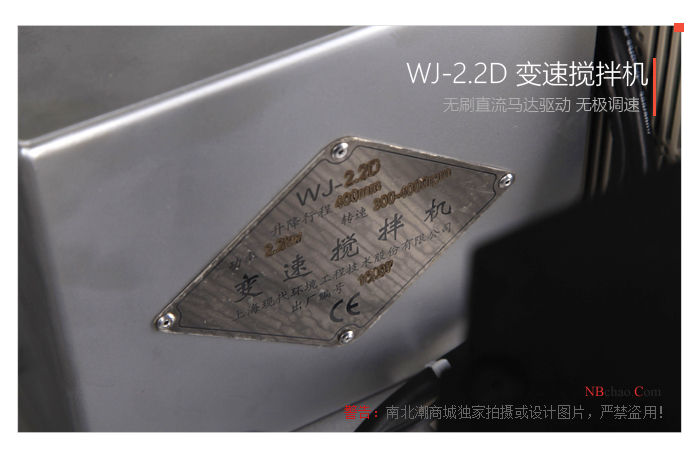

After abandoning the deficiencies of the old electric lifting and variable speed mixer, the MODERNER WJ-2.2D electric lifting and variable speed mixer adopts a new design, using a frequency converter with multi-turn method, integrated structural design, and all the wires are designed in the casing. In the middle, the integrity of the mixer is strengthened.

WJ-2.2D variable speed mixer (brushless DC type electric lifting) is mainly used for dispersing, blending and mixing various liquid materials, especially suitable for laboratory and pilot production. The motor drive of the WJ-2.2D variable speed mixer is a brushless DC variable frequency motor drive, stepless speed regulation, and has the function of stirring speed display. Due to the adoption of a brushless DC variable frequency motor, it not only avoids the disadvantage of the AC variable frequency motor's working speed being lower than the idling speed, but also avoids the trouble of replacing the brushes of the traditional DC motor. The main shaft of WJ-2.2D variable speed mixer adopts electric mode, which is easy to operate and labor-saving.

real shot

Structure brief

1. The electrical control of WJ-2.2D variable speed mixer adopts a small brushless DC motor controller, which is directly installed on the motor bracket.

2. The column adopts electric lifting mode, which is controlled by the up and down buttons.

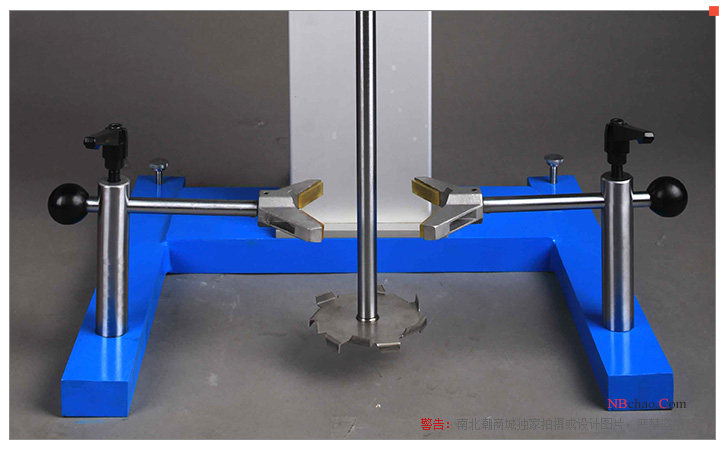

3. The stirring device is composed of stirring shaft, bearing sleeve, dispersing leaf disk, etc., and is directly connected with the motor.

4. The barrel clamping device is composed of a barrel gripper, a locking handle, etc.

Use and maintenance

1) Turn on the power.

2) Install the dispersing leaf disc.

3) The lifting of the column is controlled by the lifting button on the side, press and hold to move, release to stop.

4) To rotate the stirring shaft, press the " " button first, then slowly turn the speed control knob to adjust to the desired speed.

5) When shutting down, use the speed control knob to slow down first, and then press "STOP" to shut down, so as to avoid the material liquid splashing due to too fast increase in the next startup.

6) Fix the barrel with the clamping device. The material in the bucket should not be too full to avoid splashing when stirring. The barrel is prepared by the user or ordered separately.

Safety Precautions

WJ-2.2D variable speed mixer is used in the production process of chemical raw materials, users should establish appropriate safety and sanitation protection measures and determine rules and regulations according to relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are not within the scope of this manual.

- 1DIN 28132-1976《Agitators; diameters of shafts for agitators》

- 2HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 3HG/T 20569-2013《Mechanical mixing equipment》

- 4GB/T 21868.3-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 3: Dispersion using a high-speed impeller mill》

- 5GB/T 11543-2008《Surface active agents - The identification of emulsion for moderate to high viscosity and the evaluation method of emulsifying capability》

WJ-2.2D

WJ-2.2D