3NH NR145 handheld Colorimeter measurement aperture 8mm vertical lightweight design ≤ 0.08Delta E * ab error value

SE-

KINGWELL JZ-350 Colorimeter 8mm caliber, suitable for plastic, lame plating, design, printing, clothing, printing and dyeing, etc$ 486.00SE

KINGWELL JZ-350 Colorimeter 8mm caliber, suitable for plastic, lame plating, design, printing, clothing, printing and dyeing, etc$ 486.00SE -

IWAVE WF30-8mm Colorimeter CHINA universal color difference instrument with USB communication interface Chinese and English system 2.8TFT true color screen$ 1011.00SE

IWAVE WF30-8mm Colorimeter CHINA universal color difference instrument with USB communication interface Chinese and English system 2.8TFT true color screen$ 1011.00SE -

KINGWELL JZ-300 general Colorimeter 8mm diameter, plastic, lame plating, Eletroplating, printing industry special$ 298.00SE

KINGWELL JZ-300 general Colorimeter 8mm diameter, plastic, lame plating, Eletroplating, printing industry special$ 298.00SE -

CHINA LS170 portable Colorimeter intelligent APP color difference Tester$ 126.00SE

CHINA LS170 portable Colorimeter intelligent APP color difference Tester$ 126.00SE -

IWAVE WF32-8mm color difference Tester Color measurement 8mm$ 1450.00SE

IWAVE WF32-8mm color difference Tester Color measurement 8mm$ 1450.00SE

3NH NR145 ColoriMeterSPEC

3NH NR145 ColoriMeterDetails

3NH NR145 ColoriMeterPacking list

- SKU

- NB000739

- Lighting method

- 45°/0°

- lighting source

- LED light source

- sensor

- Silicon photodiode

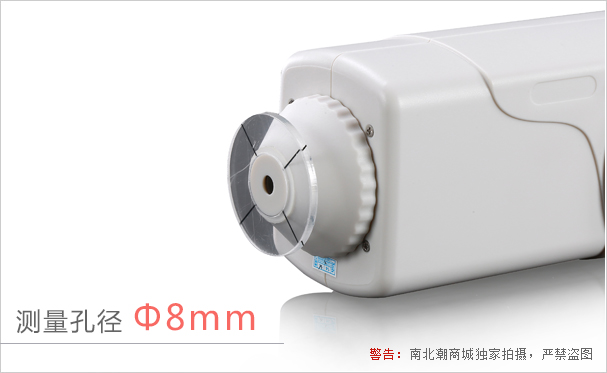

- Measurement caliber

- F8mm

- Color space

- CIE LAB, XYZ, LCh

- Color difference formula

- ΔE * from

- Other chromaticity indicators

- /

- Viewing Angle

- CIE 10 °

- Measurement light source

- D65

- display mode

- Chromatic value, color difference value/graph, pass/fail result, Color bias

- Measurement time

- 1.5s

- Sexual repeability

- Φ8mm / ΔE * from 0.08<--sep--0/>

- Inter-station difference

- ΔE * from < 0.4

- Dimensions

- 205*67*80mm

- Weight

- 400g

- Battery life

- Rechargeable Li-Ion Battery 3.7V @3200mAh

- Lighting source life

- 5 years more than 1.60 million measurements

- Display

- TFT True Color 2.8inch @(16:9)

- Data Interface

- USB

- Data storage

- 100 master standards, 20,000 samples

- Operating conditions

- 0~40℃(32~104°F)

- Storage environment

- -20~50℃

- PC software

- CQCS3 high-end quality management software

- Optional accessories

- Micro printer, powder test box

- Standards

- CIE No.15GB / T 3978

product description

Sannchi NR145 Handheld Colorimeter is a white plastic shell. In terms of structural design, it is a vertical structure. The test button is designed on the back of the Colorimeter. The front of the Colorimeter is a large LCD, and there are five operation buttons on the left. . The overall structural design of the NR145 handheld Colorimeter is well combined with ergonomics, and the handheld product is more suitable for measuring small areas, and it is not easy to stain the body.

Sannchi NR145 handheld Colorimeter is very good in any industry. The error value of ≤0.08ΔE*ab allows you to measure every time within the standard range. NR145 handheld Colorimeter makes the measurement highly anticipated. Elaborate research and development, professional production, compact shape, precision workmanship, NR145 portable Colorimeter is perfect and impeccable.

The 3nh R&D team is fully committed to various fields required by customers. In the color detection industry, it is committed to continuously developing a full range of high-quality, cost-effective products. After NR20XE, the high cost-effective 45°/0° handheld Colorimeter was launched, which has powerful functions and applied a number of differentiated innovative technologies to meet users' accurate measurement of 45° illumination/0° reception in SCE mode.

Features

● Sannchi NR145 handheld Colorimeter has built-in whiteboard parameters, no need for each calibration, to achieve fast start-up measurement;

●Double positioning: the innovative patent of light positioning and the precise positioning of the cross structure

● Sannchi NR145 handheld Colorimeter uses the three core technologies of super optical path, dynamic integration and measurement sequence, which greatly improves the stability and accuracy of measurement;

●45°/0° optical geometric structure, the measured result is more consistent with the visual effect

●8mm measuring aperture, vertical and lightweight design, suitable for more measuring occasions.

Precautions for use

1) When the battery power is lower than 30%, it is best to change the battery or charge it. Hand-held Colorimeters now use large-capacity lithium batteries, which can be recycled, which is environmentally friendly and resource-saving. When the battery is less than 30%, it is good to charge it in time, but remember to turn off the machine when charging, which can not only prolong the life of the battery , but also a maintenance of the machine itself.

2) After the product is produced, do not detect it immediately and leave it for 3-4 hours. Wait until the product temperature reaches a constant value and then use a portable Colorimeter to detect the color difference. In 3-4 hours, the temperature of the general product will drop to a constant temperature similar to the room temperature, but it is not ruled out that there are some special products that dissipate heat slowly or are not easy to cool down. It is necessary to determine a period of time according to the actual situation to make the product temperature reach constant. Then use a portable Colorimeter to test.

3) The average measurement mode is used for parts with complex shapes, and the accuracy of the collected data is higher. Because the surface of parts with complex shapes is generally not very smooth, portable Colorimeters generally have the function of multi-point measurement and averaging, which is more reliable when used on parts with complex shapes.

4) Fixed measurement personnel, standardized requirements for measurement locations and measurement directions. The pressure trigger switch of the portable Colorimeter is used by different people, and the trigger pressure is different, which also has a certain impact on the data, and this factor will not lead to the judgment of the result.

5) If there is a problem with the accuracy of the handheld Colorimeter, it must be returned to the factory for repair. It is recommended to perform manual black-and-white calibration at least once a week, or perform black-and-white calibration when the measurement data of the portable Colorimeter is inaccurate. Portable Colorimeters will produce measurement errors after being used for a period of time.

Pictures

- 1Application of color difference meter in purple rice color difference detection and its measurement procedure

- 2Application of color difference meter in detection of advertising cloth coating color difference

- 3The measurement procedure of color difference meter in metal parts

- 4Color difference analyzer for vegetable color difference detection steps

- 5General steps of using color difference meter in color difference detection of thin film prints

- 6Application and Importance of Color difference Measurement in Coating Industry

- 7Principle, characteristics and application of Spinning & weaving precision color difference instrument

- 8Teach you to understand the value of the color difference meter, the correct use of color difference meter and analysis of Color data is no longer difficult!

- 1GB/T 36392-2025《Coated paper and board for food packaging》

- 2JB/T 5595-1991《Colorimeter》

- 3 0905-2015《Standard test method for color of petroleum products by the automatic tristimulus method》

- 4YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 5GB/T 20147.3-2023《Colorimetry—Part 3:CIE tristimulus values》

- 6GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 7ISO 11664-4-2019《Colorimetry - Part 4: CIE 1976 L*A*B* Colour Space》

- 8ISO 11664-3-2019《Colorimetry - Part 3: CIE Tristimulus Values》

- 9GB/T 2374-2017《Dyestuffs—General rules for dyeing test》

- 10GB/T 22374-2018《Floor coating》

NR145

NR145