MITECH MH100 Pen Leeb Hardness Tester Manual adjustment of probe direction

mitech MH100 Leeb Hardness TesterSPEC

mitech MH100 Leeb Hardness TesterDetails

mitech MH100 Leeb Hardness TesterPacking list

- SKU

- NB007828

- Measurement range

- 170~960HLD

- Measurement direction

- Support vertical down, diagonal down, horizontal, diagonal up, vertical up

- Error of indication

- ±6HLD

- Indication Repeatability

- ±6HLD

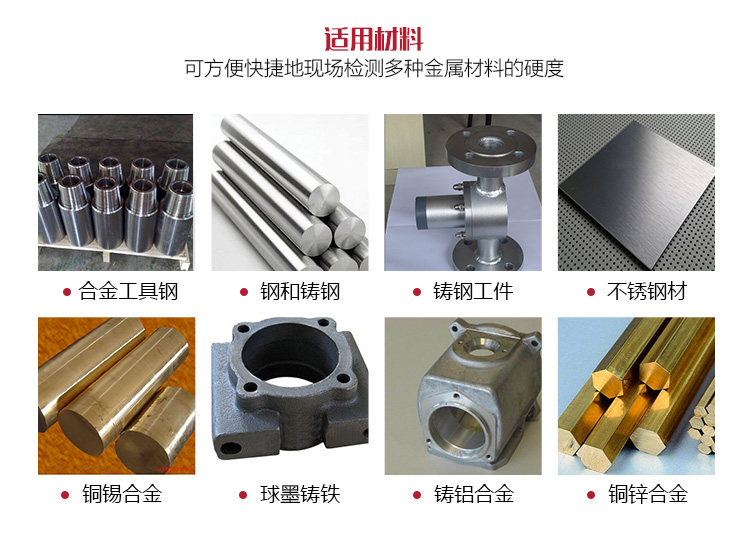

- Measurement material

- Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, ductile cast iron, cast aluminum alloy, copper zinc alloy (brass), copper tin alloy (bronze), pure copper, forged steel

- Hardness system

- HL/HB/HRC/HRB/HRA/HV/HS

- Impact energy

- 11mJ

- Impact device

- D型5.5g/7.2g

- Ball Hardness

- D1600HV

- ball head diameter

- D3mm

- Ball head material

- D type tungsten carbide

- Average surface asperity of specimen

- D型1.6μm;C型0.4μm

- Minimum depth of hardened layer

- D型≥0.8mm;C型≥0.2mm

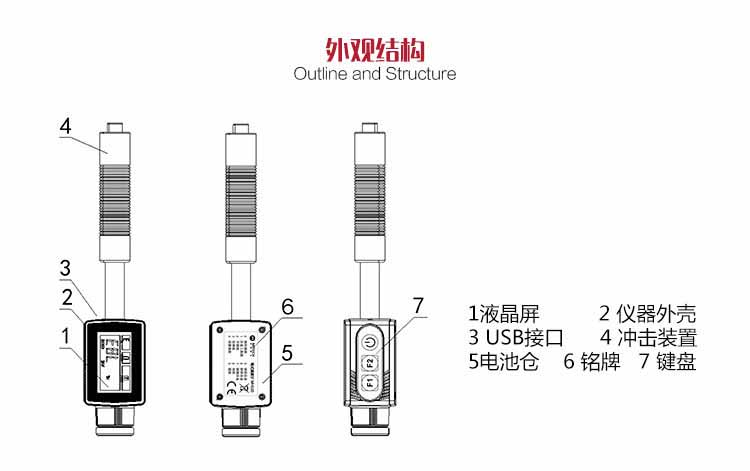

- Display

- High contrast ratio segment code liquid crystal

- Data storage

- Maximum 100 Groups (Impact 32~ 1)

- Adjustment

- Single point calibrated

- Interface

- Connect to computer to print

- Power Supply

- 3.7V (built-in polymer lithium battery)

- Power Supply

- 5V/500mA; Charging time 2.5~ 3.5 hours

- Working time

- About 200h (when the backlight is not turned on)

- Communication interface

- USB1.1 Communication interface

- working language

- Chinese

- Shell material

- ABS engineering plastics

- Dimensions

- 148*33*28mm

- Machine Weight

- 4.0KG

- PC software

- Yes.

- Impact device

- D type

Introduction

MH100Pen Leeb Hardness TesterAlso known as:The pocket Hardness Tester, based on the Leeb hardness measurement principle, can easily and quickly detect the hardness of a variety of metal materials on site, and supports the free conversion between Leeb, Brinell, Rockwell and other hardness systems.MH100Integrated and exquisite design, small size, easy to carry, high integration, stable and reliable performance, support data transmission and printing and storage functions. It is widely used in metal processing and manufacturing, special equipment, failure analysis of long-lasting components, commodity inspection and other fields. It is particularly suitable for on-site hardness testing of large parts and non-detachable parts. It is a professional precision instrument required to improve the production qualification rate and save costs.

Features

1. Based on the principle of Leeb hardness measurement, the hardness test can be carried out on a variety of metal materials, and the measurement results can be converted into Leeb (HL), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), and RockwellA (HRA), Vickers (HV), Shore (HS).

2. High-contrast segment code LCD display, simple and convenient operation.

3. Support "Steel" material, when testing the "forged steel" specimen with D-type impact device, the HB value can be directly read without manual checking.

4. It has the function of calibration of value indication software.

5. It can store up to 100 groups of hardness measurement data (impact times 32~1), and each group of data includes single measurement value, average value, impact direction, times, material, hardness system and other information.

6. The remaining power display can display the remaining power of the battery in real time, and there is a charging process indication to display the charging process.

7. USB communication interface, which can easily and quickly communicate with the PC.

8. Equipped with data processing software, it has rich functions such as transmitting measurement results, measuring value storage management, measuring statistical analysis, printing measurement reports, and setting instrument parameters in batches.

9. Built-in lithium battery and charging control circuit, can work continuously for no less than 200 hours, and has power-saving functions such as automatic sleep and automatic shutdown.

10. Integrated and exquisite design, small size, easy to carry, high integration, stable and reliable performance, suitable for harsh on-site operating environment, anti-vibration, shock and electromagnetic interference.

Functional use

Mold cavities

Bearings and other parts

Failure analysis of pressure vessels, turbine-generator sets and their equipment

Heavy-duty workpieces

Installed mechanical or permanently assembled components

Workpieces with a tight test space

Formal original records of test results are required

Material division of metal material warehouse

Rapid inspection of multiple measuring parts in a large area of large workpieces

Comparison of Mattel's full range of Leeb Hardness Testers

MH100

MH100