MODERNER SFJ-400 Sanding, Dispersion, Stir Multi-purpose Machine (Variable Frequency Speed Regulation) for Chemical Laboratories

SEModerner SFJ-400 Sanding, Dispersion, Stirring Multipurpose MachineSPEC

Moderner SFJ-400 Sanding, Dispersion, Stirring Multipurpose MachineDetails

Moderner SFJ-400 Sanding, Dispersion, Stirring Multipurpose MachinePacking list

- SKU

- NB000792

- Motor Input Power

- 550W

- Speed regulation range

- 0~7500rpm

- Lifting stroke

- 240mm

- Dimensions

- 450*420*550mm

- Power

- 220V 50Hz

- Weight

- 33kg

- relevant standards

- GB/T 21868.3、ISO 8780-3

- Sand disc diameter

- Φ45/60mm

- Dispersing disc diameter

- Φ50/60mm

Introduction

MODERNER SFJ-400 sanding, dispersing and mixing multi-purpose machine is a type of frequency conversion speed regulation, which can realize three functions of sanding, dispersing and mixing, and is suitable for chemical laboratories. MODERNER SFJ-400 sanding, dispersing and mixing multi-purpose machine adopts special frequency conversion motor, low heat generation, no brush; the frequency converter adopts multi-circle speed control knob, the display screen directly displays the stirring speed, and is easy to operate; this equipment is equipped with multiple A variety of optional sanding, dispersing, and stirring blades are suitable for different laboratory test requirements, and the multi-functional type is more cost-effective.

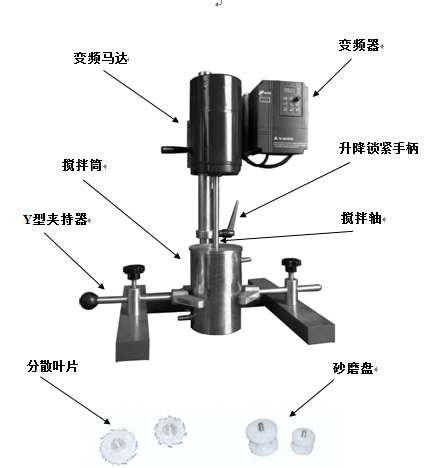

Outline structure diagram

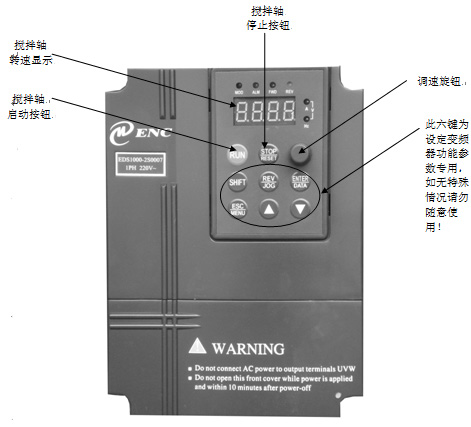

Inverter panel operation instruction diagram

Steps for usage

1. Select the appropriate blisk and screw it to the stirring shaft.

2. Loosen the lifting and locking handle, adjust the height of the blisk and the bottom of the mixing drum (can be positioned with a positioning ring), and then raise the stirring shaft for feeding and placing the mixing drum.

3. Position and fix the mixing drum with the Y-shaped holder.

4. Lower the stirring shaft to an appropriate position, cover the mixing drum cover, and tighten the lifting and locking handle.

5. Confirm that there is no contact between the blisk and the mixing drum, and then start stirring.

6. After the stirring is completed, first lower the stirring speed appropriately and then press the stop button.

7. After each work of SFJ-400 sanding, dispersing and mixing multi-purpose machine, please clean and maintain the blade disc, mixing drum and main equipment in time for subsequent use.

Precautions for use

1. The speed of the stirring shaft is controlled by the speed control knob on the frequency converter (rotate clockwise for acceleration); before starting the stirring shaft to rotate, please confirm that the rotating speed is at a low speed position (to avoid the splash of the material liquid caused by too fast rise), after starting Then use the speed control knob to quickly adjust to the appropriate position.

2. The inverter parameters have been set before leaving the factory, please do not change them at will.

3. Before stopping the stirring, it is advisable to reduce the stirring speed appropriately, and then press the stop button, so as to avoid flying liquid caused by too fast rise in the next startup.

Rotation speed - line speed comparison table

| Dispersion blade diameter (mm) | Speed (r/min) | Linear speed (m/s) |

| φ40 | 1900 | 4 |

| 3800 | 8 | |

| 5700 | 12 | |

| 7500 | 15.7 | |

| φ50 | 1900 | 4.5 |

| 3800 | 9 | |

| 5700 | 13.5 | |

| 7500 | 17.7 | |

| φ50 | 1900 | 5 |

| 3800 | 10 | |

| 5700 | 15 | |

| 7500 | 19.6 | |

| φ60 | 1900 | 6 |

| 3800 | 12 | |

| 5700 | 18 | |

| 7500 | 23.6 |

SFJ-400

SFJ-400