MODERNER KS-370D Coating Rapid Dispersion Tester, Floor-to-Floor Bottle Clamp

SE-

MODERNER KS-370A Coating Blue-devil Dispersion Testing Machine, Column Clamp Type, Blue Devil

MODERNER KS-370A Coating Blue-devil Dispersion Testing Machine, Column Clamp Type, Blue Devil -

Qiwei FS-1100D Experimental Disperser (Digital Display High Speed)$ 391.00SE

Qiwei FS-1100D Experimental Disperser (Digital Display High Speed)$ 391.00SE -

Qiwei FS-1100D Experimental Disperser (digital display high-speed) with 2.5L Mixing Tank$ 402.00SE

Qiwei FS-1100D Experimental Disperser (digital display high-speed) with 2.5L Mixing Tank$ 402.00SE -

Qiwei FS-1100D Experimental Disperser (digital display high-speed) with 5L Mixing Tank$ 467.00SE

Qiwei FS-1100D Experimental Disperser (digital display high-speed) with 5L Mixing Tank$ 467.00SE -

Qiwei JFS-750 Dual Axis Disperser 750W Power$ 633.00SE

Qiwei JFS-750 Dual Axis Disperser 750W Power$ 633.00SE

Moderner KS-370D Coating rapid dispersion testing machine (floor clamping bottle)SPEC

Moderner KS-370D Coating rapid dispersion testing machine (floor clamping bottle)Details

Moderner KS-370D Coating rapid dispersion testing machine (floor clamping bottle)Packing list

- SKU

- NB000796

- Motor Power

- 550W

- Rotation speed of crankshaft

- 660rpm

- Spindle reciprocating amplitude

- 16mm

- Spindle oscillation angle

- 30deg

- Power

- 220V 50Hz

- Dimensions

- 800*520*530mm

Introduction

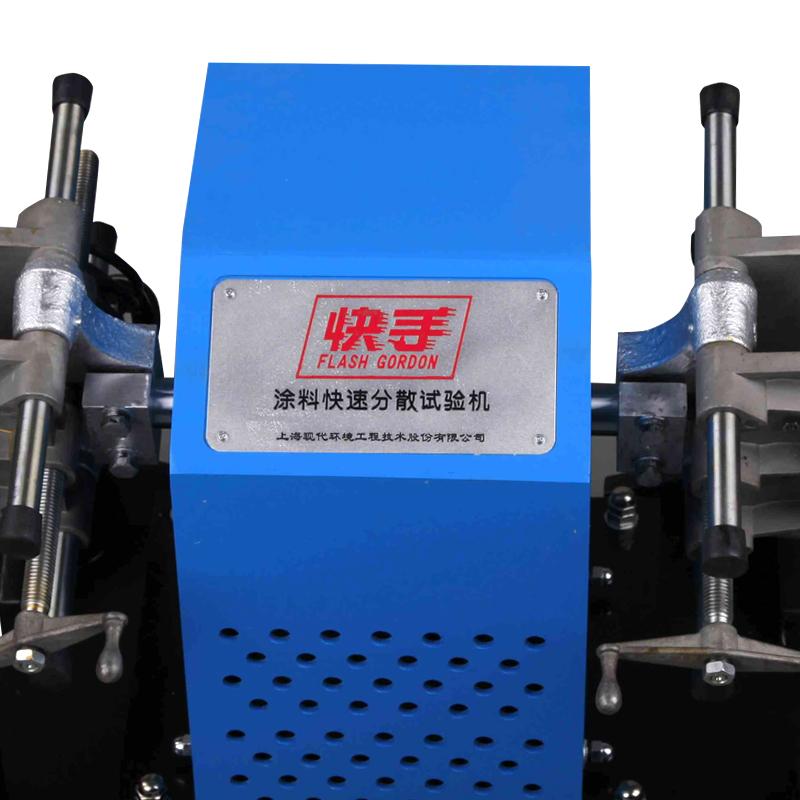

MODERNER KS-370 floor-standing paint rapid dispersion testing machine has two models: KS-370 C (floor-standing clamp tank) / KS-370D (floor-standing clamp bottle) . The floor-standing type is more stable. The coating rapid dispersing machine, also known as Blue-devil, is mainly used in laboratories such as coatings, dyes, and inks to quickly and effectively vibrate and disperse materials. It can also conduct comparative dispersion tests on multiple materials at the same time.

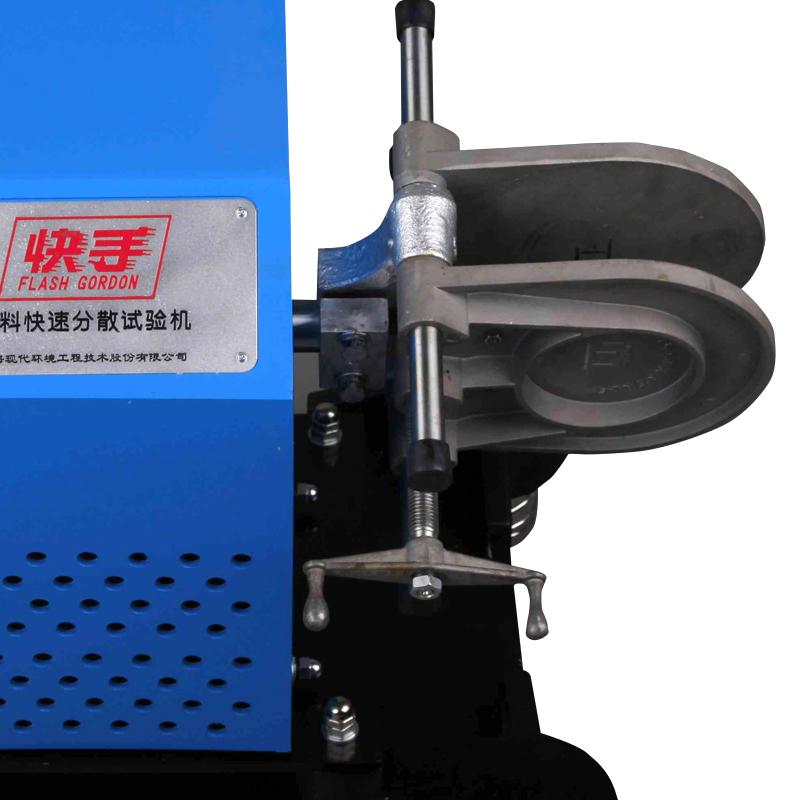

KS-370D (floor-standing clamp bottle) clamp bottle coating rapid dispersion testing machine is equipped with small glass bottle clamps (4 can be placed on each side, eight in total on both sides). The volume of the small glass bottles provided is approximately 195mL.

Comparison of parameters of floor-standing paint rapid dispersing machine

| model | KS-370C ( floor clamp tank ) | KS-370D (floor clamp bottle) |

| motor | 550W | 550W |

| crankshaft speed | 660rpm | 660rpm |

| Spindle reciprocating amplitude | 16mm | 16mm |

| Spindle swing angle | 30deg | 30deg |

| using electric | 220V 50Hz | 220V 50Hz |

| Dimensions | 800x520x530mm | 800x520x530mm |

Product installation instructions

The KS-370D floor-standing paint rapid dispersion testing machine is relatively simple to install. Just place the four foot springs in the spring seat holes on the bottom plate of the main machine and it can be used.

Steps

1. Put the materials to be dispersed and the grinding media (grinding beads) into the tank (or bottle). For the material-bead mass ratio, please refer to the table below.

| grinding media | glass bead | steel ball |

| Material-bead mass ratio | 1:2~3 | 1:3~4 |

2. Place the sealed tank (or bottle) into the clamping device and turn the handle to clamp it. The clamping force must be appropriate to avoid damaging the can (or bottle) due to excessive force or causing damage to the clamping device.

3. Try to avoid using cans (or bottles) on one side. If you do need one-sided use, clamp a weighted can (or bottle) of water on the other side.

4. If small glass bottles are used in the clamping jar configuration, in order to improve the dispersion efficiency, two small glass bottles can be clamped at a time at a symmetrical position near the outside of the single-side clamping plate. (Pay attention to the balance on both sides of the clamping device)

5. According to the required grinding time, set the timer (randomly supplied, please refer to the timer manual for operation), and start the KS-370 column-type paint rapid dispersion testing machine.

6. After dispersion is completed, please make sure that the KS-370D floor-standing paint rapid dispersion testing machine is completely stationary before turning the handle to loosen the clamping device and take out the material tank (or bottle).

7. After the work is completed, please disconnect the power supply and perform cleaning and care work in time.

Note: Customers are asked to check the relevant regulations of different products for the detailed steps and judgment standards of material operation, which are not within the scope of the instructions of the testing machine.

How to use the four-hole holder configured to clamp bottles

1. Loosen the ingot nuts at both ends and separate the four-hole holder up and down.

2. Place the small glass bottle into the lower holder (the same specifications as the small glass bottle provided with the machine).

3. Cover the upper holder and tighten the ingot nuts at both ends.

4. Install the entire holder on the Blue-devil holder.

5. When installing, please note that the two grooves on the four-hole holder need to be aligned with the cylindrical pins on the Blue-devil holder; the positioning block on the four-hole holder needs to be above the Blue-devil holder.

Precautions for use

1. After using the new KS-370D floor-standing coating rapid dispersion testing machine for 100 hours, please replace the crankcase lubricating oil. In the future, you only need to check and add it in time for daily use.

(Lubricating oil brand: Great Wall brand heat setting machine lubricating oil 4402-1)

2. The total mass of the clamped material tank (or bottle) should not exceed 5 kilograms to avoid shortening the service life of the paint rapid dispersion testing machine.

3. Please clean and maintain the guide rod and screw of the holder in time to avoid rust or residual foreign matter that may cause difficulty in clamping.

4. The floor-standing paint rapid dispersion testing machine will generate a lot of heat when working. The paint rapid dispersion testing machine needs to be placed in a workplace with good ventilation conditions.

5. In order to extend the service life of the paint rapid dispersion testing machine, after each operation exceeds 90 minutes, please stop the machine for 10 to 15 minutes to allow the machine to cool down before starting it again.

KS-370D

KS-370D