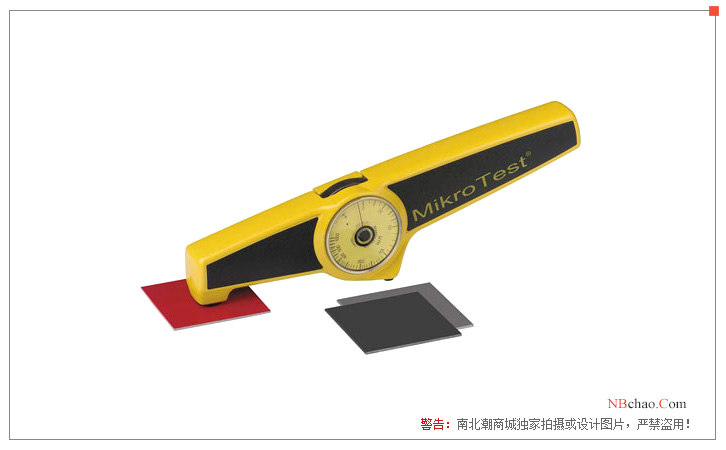

German EPK MikroTest F6 McCourt coated platings Thickness Gauge, thickness measurement: 0~1000μm

SE Boutique

ElektroPhysik MikroTest F 6 McCourt platings Thickness GaugeSPEC

ElektroPhysik MikroTest F 6 McCourt platings Thickness GaugeDetails

ElektroPhysik MikroTest F 6 McCourt platings Thickness GaugePacking list

- SKU

- NB007976

- Measurement principle

- mechanical

- Measurement range

- 0~1000μm

- margin of error

- +/- 5μm/5% read value

- Minimum measurement surface

- 30mm

- Minimum radius of curvature

- Convex 8mm; Concave 25mm

- thinnest substrate

- 0.5mm

- probe

- Integrated probe

- Calibrated Certificate

- none

- Calibrated mode

- No need to calibrate

- Unit display

- μm

- statistical function

- none

- icon function

- none

- Interface

- none

- Data storage

- none

- Power Supply

- No power or battery required

- Standards

- DIN EN ISO2178, DIN 50982, ASTM B 499, E 376, ASTM D 1186, ASTM G12, ASTM B 530, BS5411, ISO2361 standards

- Display screen

- dial

- Operating temperature

- -20~100℃

- Machine Weight

- 560G (including instrument case)

- Machine size

- 215*55*29mm

- Packaging Dimensions

- 235*185*46mm

Introduction

EPK MikroTest F6 is an accurate and error-free measurement of the thickness of paint and plating layers on steel.

The MIKROTEST Coating Thickness Gauge measures the thickness of all non-magnetic coatings on steel (e.g. lacquer, powder coat, plastic, zinc, copper, tin and nickel). Fast, accurate and non-destructive, MICROTEST has been the most widely used instrument for the automatic determination of coating thickness for more than 30 years. Germany's "know-how" shows that it has the highest level of magnetic cladding Thickness Gauge in terms of process technology and precision.

Apply standards

The EPK MikroTest F6 is compliant with DIN EN ISO2178, DIN 50982, ASTM B 499, E 376, ASTM D 1186, ASTM G12, ASTM B 530, BS5411, ISO2361.

Features

MIKROTEST OPERATES FULLY AUTOMATICALLY. It has the following very good characteristics when in use:

1) Automatic measurement will not occur misoperation;

2) Simple setup and measurement;

3)No calibration required;

4)No batteries or other power sources are required;

5)Automatically report the thickness reading;

6)With a non-destructive probe, a little bit of measurement;

7)The metal armor is suitable for frequent outdoor operation and use, and is protected from mechanical impact;

8)Resistant to mechanical shock, acid and solvent corrosion;

9)The balancing device eliminates the influence of gravity and can accurately measure in any direction and in the tube.

Pictures

Comparison of EPK MikroTest coating Thickness Gauge series

| Model | Measuring range | Readability | Minimum measuring area diameter | The minimum radius is convex and concave mm | Minimum thickness of the substrate | Suitable for: |

| MIKROTEST G 6 | 0-100μm | 1 μm or 5% reading | 20mm | 5mm;25mm | 0.5mm | Electroplating layer on steel, iron, lacquer, enamel, plastic, rubber layer |

| MIKROTEST F 6 | 0-1000μm | 5 μm or 5% reading | 30mm | 8mm;25mm | 0.5mm | |

| MIKROTEST S3 6 | 0.2-3mm | 5% reading | 30mm | 15mm;25mm | 1.0mm | |

| MIKROTEST S5 6 | 0.5-5mm | 5% reading | 50mm | 15mm;25mm | 1.0mm | |

| MIKROTEST S10 6 | 2.5-10mm | 5% reading | 50mm | 15mm;25mm | 2.0mm | |

| MIKROTEST S20 6 | 7.5-20mm | 5% reading | 100mm | 100mm;150mm | 7.0mm | |

| MIKROTEST NIFE50 6 | 0-50μm | 2 μm + 8% reading | 20mm | 10mm;25mm | 0.5mm | Nickel plating on iron |

| MIKROTEST NI50 | 0-50um | 1 μm or 5% reading | 15mm | 5mm;25mm | - | Nickel plating on a non-ferromagnetic metal substrate |

| MIKROTEST NI100 | 0-100um | 1 μm or 5% reading | 15mm | 5mm;25mm | - |

- 1What are the Thickness Gauges that can test the thickness of underwater coatings?

- 2Can the coating Thickness Gauge measure the thickness of pipes?

- 3McCourt Coating Thickness Gauge Learn about these advantages, you can't choose the wrong instrument!

- 4Precautions for the use of MiKroTest McCourt Mechanical Coating Thickness G6

- 5What are the coating Thickness Gauges suitable for measuring the thickness of the coating in explosion-proof occasions?

- 6EPK Coating Thickness Gauge FAQ

- 7Key points for maintenance of coating Thickness Gauge

- 8Introduction of Several New Coating Thickness Gauges and Coating Holiday Detectors

王叔孙 - 《介绍几种涂镀层测厚仪与涂层针孔检测仪》

- 9EPK McCourt Coating Thickness Gauge Beauty Appreciation

- 10The performance of electroless deposited metal coatings

- 1NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

- 5ISO 2361-1982《Electrodeposited Nickel Coatings On Magnetic And Non-Magnetic Substrates - Measurement Of Coating Thickness - Magnetic Method》

- 6ISO 2808-2007《Paints and varnishes - Determination of film thickness》

- 7JB/T 9857-2010《General technical conditions for rock drilling machinery and pneumatic tool painting》

- 8GB/T 1733-1993《Determination of water resistance of paint film》

- 9GB/T 13452.2-2008《Paints and varnishes - Determination of film thickness》

- 10GB/T 11374-1989《Measuring method of nondestructive heat spray-on lining thickness》

MikroTest F 6

MikroTest F 6