Dasheng OF700 (DA700 series dedicated) Air Compressor head, power 750w

SEDaSheng OF700 (for DA700 series) Machine headSPEC

DaSheng OF700 (for DA700 series) Machine headDetails

DaSheng OF700 (for DA700 series) Machine headPacking list

- SKU

- NB000800

- type

- oil free

- Displacement

- 152L/min at 0Bar,68L/min at 5Bar

- output power

- 750w

- Noise value值

- 59dB(A)

- Dimensions

- 270*128*190mm

- Weight

- 11Kg

- speed

- 1400rpm

- exhaust pressure

- 5~8Bar

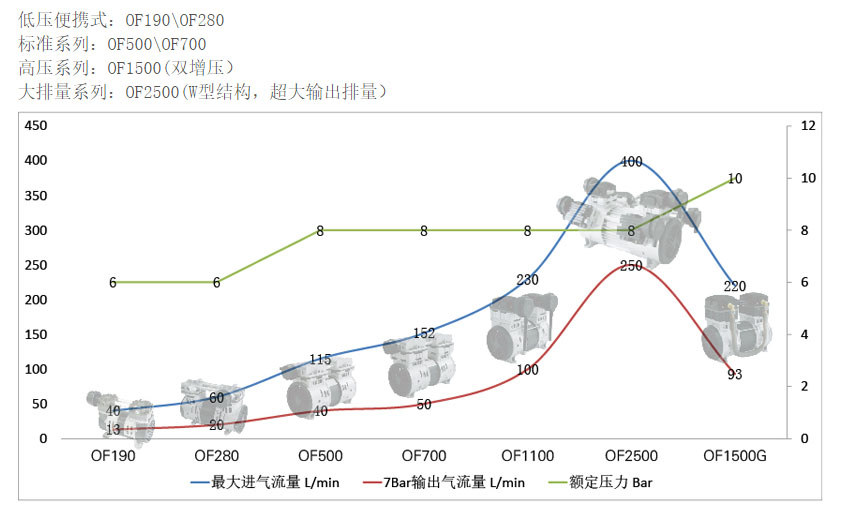

Introduction of OF700 Air Compressor head

OF700 Air Compressor head (also known as pump head) is a pump head produced by Dasheng for use with silent oil-free Air Compressors, suitable for DA700 series Air Compressors. The head OF700 of Dasheng Air Compressor is a new motor, which greatly improves the performance on the basis of the old model. All parts of the machine head, including screws and reinforcing rods, are made of stainless steel, which has better corrosion resistance, and fans are used to blow heat to improve heat radiation.

Note: The pump head is broken during the use of the Air Compressor, and the pump head can be purchased separately for replacement, which saves costs without scrapping the whole machine.

Dasheng Air Compressor classic pump head

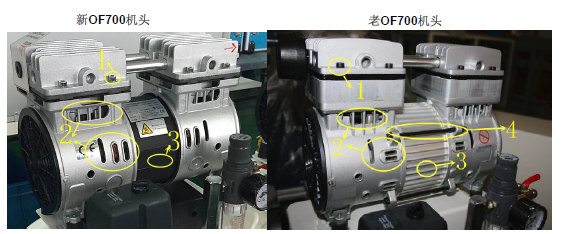

Comparison of old and new Air Compressor heads

1. External update

1) Replace all screws of OF500/OF700 Air Compressor head with stainless steel

2 ) Enlarging cooling holes to improve heat dissipation

3 ) Remove the old aluminum case, the fan blows heat directly through the GAB between the motor case and the black surface. (The old design with aluminum actually blocks the heat, not radiates it, compare 3 in the picture below)

4 ) The reinforcing rod is updated to stainless steel, and enters the inside of the machine head from the external motor.

2. Heat radiation update

1 ) The new model removes the cover so that the fan blows the heat through the gap between the motor housing and the black. The image below shows a partial cleaning of the dust on the black body area, which is where the heat is located.

2 ) Older models had aluminum shrouds over the motors, the old shrouds would actually block the heat instead of radiating it.

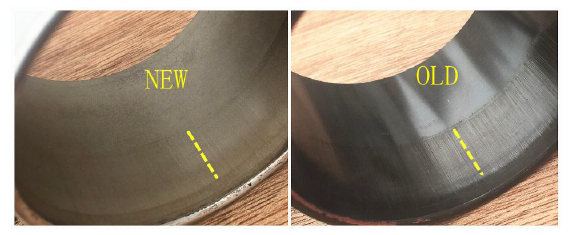

3. Interchange of parts

All parts of the new and old machine heads are interchangeable except the lower cups and cylinder liners.

4. Comparison of life expectancy

1) a. The standard thickness of the leather cup of the new machine head is 0.8mm, and it is still in good condition after 1500 hours of ultimate load test, with 6.3% wear.

b. The standard thickness of the leather cup of the old machine head is 0.8mm, and after 1500 hours of ultimate load test, 55% of it is worn.

2) The new machine head uses 100% copper wires to increase the heat radiation speed and prolong the life of the machine head.

3) a. The new ceramic coated barrel jacket is still in good condition after 1500 hours of testing with no obvious scratches seen.

b. The surface of the old cylinder jacket has obvious scratches and needs to be replaced after 1500 hours of testing.

- 1Pressure barrel conveying system and operation

- 2Introduction to the advantages and disadvantages of pressure vessel feeding

- 3Air Compressor type and working principle

- 4What are the types of commonly used laboratory equipment?

- 5Calculation method of chilling down water consumption of Air Compressor

- 6Factors to consider when choosing an Air Compressor

- 1GB/T 12929-2008《Marine reciprocating Air Compressor for high pressure》

- 2GB/T 25358-2010《Packaged rotary oil-free Air Compressors for petroleum and natural gas industries》

- 3GB/T 13928-2015《Reciprocating minitype Air Compressors》

- 4GB/T 13279-2015《Stationary reciprocating Air Compressors for general use》

- 5GB/T 33625-2017《Oil-free reciprocating Air Compressors on locomotives and power cars》

OF700 (for DA700 series)

OF700 (for DA700 series)