Pushen ZS-120 manual Ink Proofer Roller 120LPI line number Colorimeter, proofing roller

SEPushen ZS-120 Manual Ink ProoferSPEC

Pushen ZS-120 Manual Ink ProoferDetails

Pushen ZS-120 Manual Ink ProoferPacking list

- SKU

- NB000810

- number of reticulated lines

- 120 lines

- Hole shape

- quadrilateral pyramid

- Anilox roll material

- stainless steel

- print width

- 70mm

- application

- Flexo printing, gravure printing

Introduction

PrussiaZS(28012) color wheelThe metal anilox roller is 120 threads, with a quadrangular prism mesh shape, which is completed by electronic engraving technology and has a wide range of applications. The color wheel is composed of metal anilox roller, rubber roller and handle, and the width of the printing surface is 70mm, which is simple and convenient to operate, and evenly coated. The color wheel is widely used in ink, flexo, gravure ink proofing and other industries.

Parameters

| Model | Number of Anilox Roller Lines (LPI) | Print width | compose |

| ZS(28012) | 120 | 70mm | Handles, metal anilox rollers, rubber rollers |

Note: The unit of the number of lines of the color wheel is expressed by LPI, i.e., Lines per Inch: number of lines per square inch.

(The number of threads of the metal anilox roller is inversely proportional to the thickness of the wet film, that is, the larger the number of threads, the smaller the thickness of the wet film)

Features

1. PushenZS(28012)The color wheel is composed of a handle, a metal anilox roller and a rubber roller.

2. It adopts the shape of a quadrangular pyramid and the width of the printing surface is 70mm.

3. The color wheel is novel in style, simple to use, convenient and intuitive in effect, and strong in proofing.

4. The color wheel is a tool required for the production of gravure and aniline inks.

5. The unit of the number of lines of the color wheel is represented by LPI, that is, Lines per Inch: the number of lines / per square inch.

Live shot

Pushen ZS (28012) 120 lines of color wheel inner packaging display diagram

Pushen ZS (28012) 120 lines of the color wheel overall display diagram

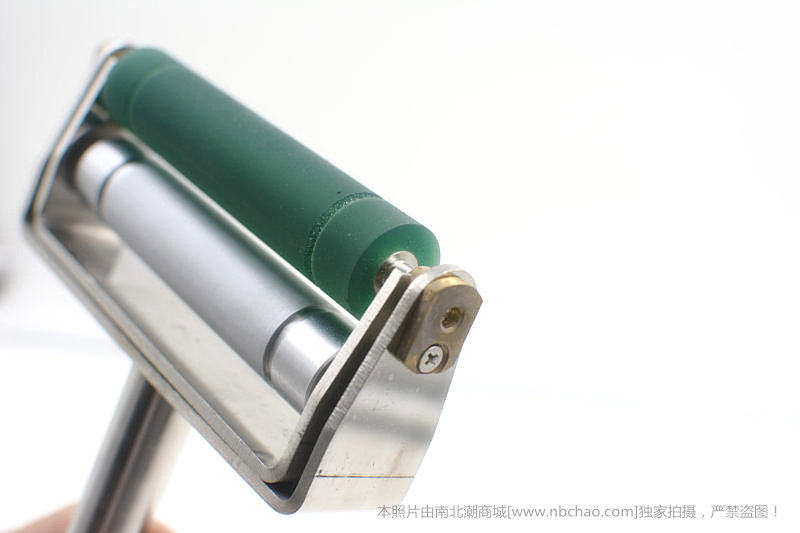

Pushen ZS (28012) 120 line color wheel anilox roller details

Pushen ZS (28012) 120 line color wheel handle display diagram

Pushen ZS (28012) 120 line exhibition color wheel side display

Pushen ZS (28012) 120 line color wheel product certificate

Applications

ZS(28012)ColorGravure, aniline inks, or other liquid coatings can be applied to a variety of substrates to produce reproducible samples.

How to maintain the color wheel

1. Use a mesh microscope to inspect the mesh holes regularly.

2. Test the viscosity of the ink and clean the anilox roller in time.

3. When the anilox roller is not in use, it should be stored with a protective sleeve of the anilox roller to keep the surface clean and play a role in buffering and absorbing vibration.

4. Use a good squeegee to control the pressure between the squeegee and the anilox roller, and put a magnetic filter in the ink groove under possible conditions to reduce the ink impurity particles, reduce the wear of the anilox roller, and prolong the service life.

Parameter table of all models

| Model | Number of anilox roller lines | Print width | compose |

| ZS(28011) | 100(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28012) | 120(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28013) | 150(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28014) | 160(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28015) | 180(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28016) | 200(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28017) | 220(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28018) | 250(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

| ZS(28019) | 300(LPI) | 70mm | Handles, metal anilox rollers, rubber rollers |

ZS-120

ZS-120