Pushen ZS-300 manual Ink Proofer 300LPI Gravure ink Coating etc

SEPushen ZS-300 Manual Ink ProoferSPEC

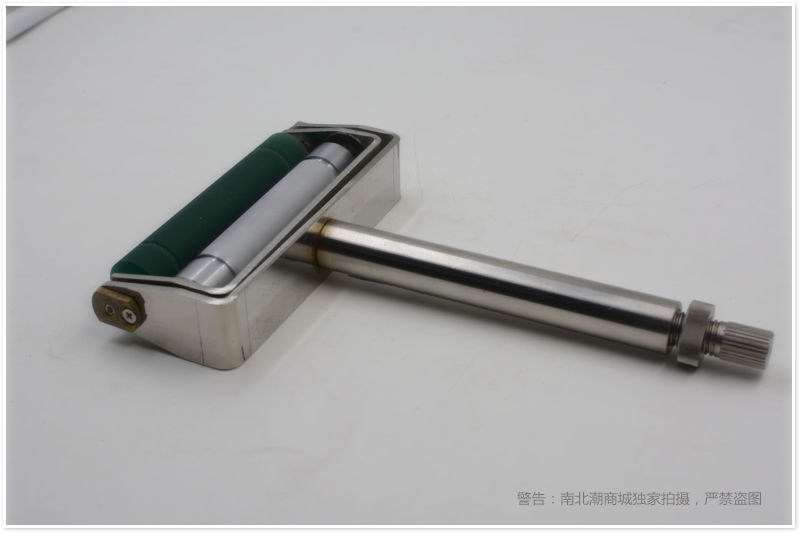

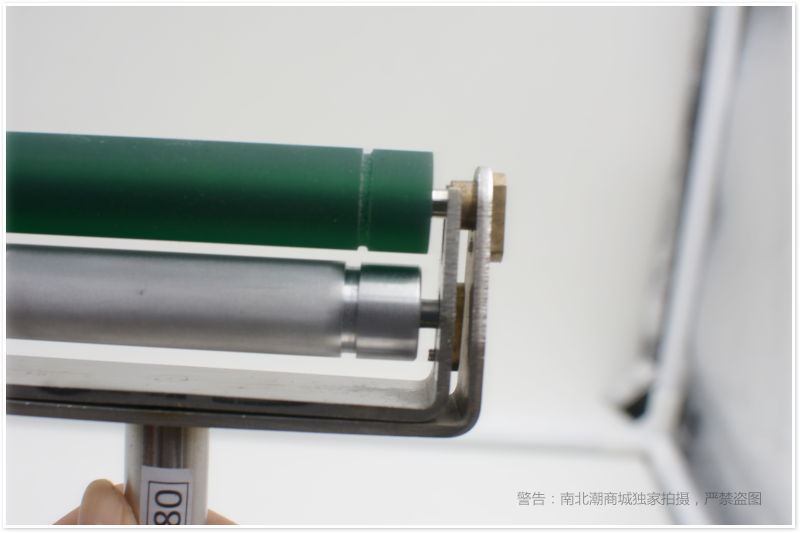

Pushen ZS-300 Manual Ink ProoferDetails

Pushen ZS-300 Manual Ink ProoferPacking list

- SKU

- NB000817

- Number of reticulated lines

- 300 lines

- Mesh shape

- quadrangular pyramid

- Anilox roll material

- stainless steel

- Printing width

- 70mm

- application

- Flexo, gravure

Introduction

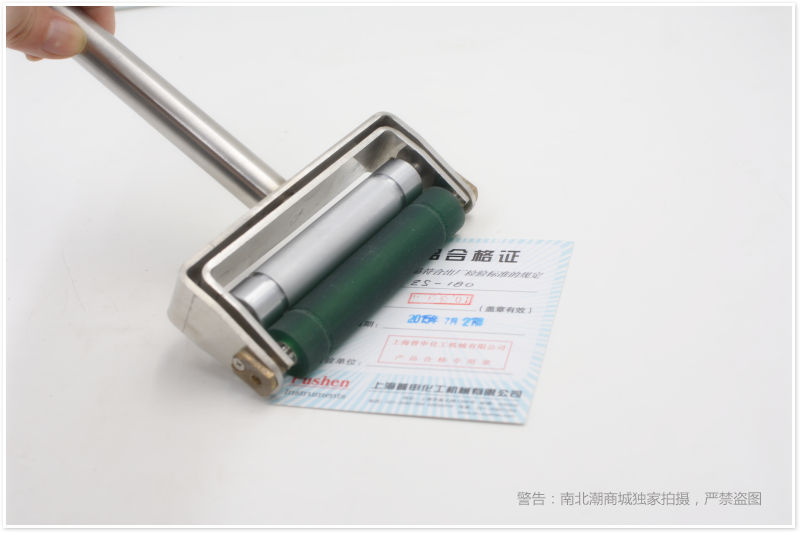

Pushen ZS (28019) color wheel is composed of metal anilox roller, rubber roller and handle, which can apply gravure, aniline ink or other liquid paints on various substrates to obtain reproducible samples. Pushhen ZS(28019) color development wheel has an anilox roll line number of 300LPI and a printing surface width of 70mm. Pushen Zhan color wheel is novel in style, easy to use, intuitive in effect, and strong in proofing authenticity. It is a necessary tool for gravure printing and aniline ink production.

Specifications

| model | Anilox roll line number (LPI) | Printing width (mm) | composition |

| ZS(28019) | 300 | 70 | Handle, metal anilox roller, rubber roller |

Note: The line number unit of the color wheel is represented by LPI, that is, Lines per Inch: line number/per square inch.

( The number of lines of the metal anilox roller is inversely proportional to the thickness of the wet film, that is, the larger the number of lines, the smaller the thickness of the wet film )

real shot

Color wheel maintenance method

1. Use a mesh microscope to check the mesh regularly

2. Check the ink viscosity and clean the anilox roller in time

3. When the ZS ( 2 8 0 19) color development wheel anilox roller is not in use, use the anilox roller protective cover for storage

4. Use a good scraper and control the pressure between the scraper and the anilox roller. If conditions permit, put a magnetic filter in the ink tank to reduce the impurity particles in the ink and reduce the wear of the anilox roller. extend its service life.

How to choose the appropriate anilox roll line number?

1. Solids, lines, text, etc. require a large amount of ink, so choose a lower number of screen lines; a color screen pattern requires a small amount of ink, and choose a higher number of screen lines.

2. The fineness of the printed matter depends on the number of dot lines. It is better to maintain a ratio of about 4:1 between the number of anilox rolls and the number of dot lines of the printing plate.

3. Generally, if the ink absorption is high, choose the one with a low number of texture lines; if the ink absorption is small, choose the one with a high number of texture lines.

Full model parameter table

| model | Anilox roll lines | Printing width | composition |

| ZS ( 2 8 0 11 ) | 100 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 12 ) | 120 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 13 ) | 150 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 14 ) | 160 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 15 ) | 180 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 16 ) | 200 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 17 ) | 220 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 18 ) | 250 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

| ZS ( 2 8 0 19) | 300 (LPI) | 70mm | Handle, metal anilox roller, rubber roller |

ZS-300

ZS-300