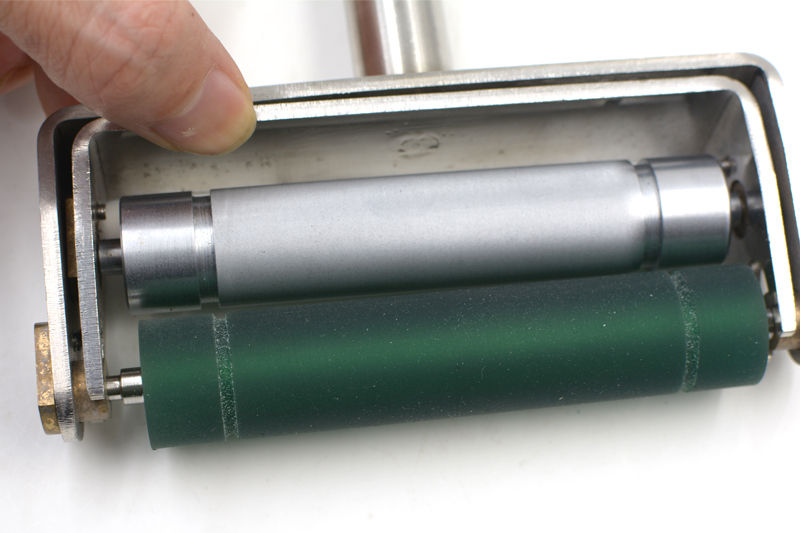

Pushen 100 line manual Ink Proofer metal anilox roller, quadrilateral pyramid mesh shape

SEPushen 100 line manual Ink Proofer metal roller is an important component of manual Ink Proofer, which affects the ink supply by the number of lines of the anilox roller. The number of anilox lines is 100LPI, the shape of the net is quadrilateral pyramid, and the width of the print surface is 70mm.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

Pushen 100 lines Manual Ink ProoferSPEC

Pushen 100 lines Manual Ink ProoferDetails

Pushen 100 lines Manual Ink ProoferPacking list

- SKU

- NB000819

- number of reticulated lines

- 100LPI

- Hole shape

- quadrilateral pyramid

- print width

- 70mm

100 lines

Manual Ink Proofer

Introduction

Pushen 100-line developing color wheel metal roller is an important component of the developing color wheel, and the amount of ink supply is affected by the number of lines of the anilox roller. The anilox roller transfers ink quantitatively and evenly to the graphic part of the printing plate. The uniformity and accuracy of ink transfer by anilox rollers are determined by parameters such as the number of anilox lines, cell shape, cell opening, depth, opening degree, anilox angle and cell volume.

Note: The number of lines of the metal anilox roller is inversely proportional to the thickness of the wet film, that is, the greater the number of lines, the smaller the thickness of the wet film.

Specifications

| model | Product name | Number of lines | Cell shape |

| 100 lines | Metal anilox roller | 100LPI | quadrangular pyramid |

Product actual pictures

FAQ

QDo you have the manual Ink Proofer metal roller required by GB/T13217.1 standard?

A

This 100-wire manual Ink Proofer metal roller will do.

QWhat is the relationship between the ink supply of the anilox roller and the number of anilox lines? What ratio is better between the number of anilox lines and the number of dot lines?

A

Hello, in theory, the ink supply of the anilox roller decreases with the increase of the number of anilox lines. The higher the number of anilox lines, the smaller the ink supply and the better the relative uniformity. In addition, for the proportional relationship between the number of anilox lines and the number of dot lines of the anilox roller and the number of dot lines of the printing plate, it is better to maintain a ratio of about 4:1.

QWhat is the mesh shape of this metal anilox roller? Can it be used for scraper-type flexographic printing ink supply?

A

Hello, this Pushen metal anilox roller is a quadrilateral pyramid-shaped mesh hole, which is generally used in the form of a double-roller ink supply. For the scraper-type ink supply form, it is recommended to use the mesh shape of a quadrilateral prism and a hexagonal prism.

QIs the rubber rod above or below? How to use?

A

The metal anilox roller is on the top and the rubber roller is on the bottom. The manual Ink Proofer uses a movable handle with two linked rollers, one metal anilox roller and the other rubber roller in contact with the sample fluid. The coating is injected between the two rollers and rotated to the equipment through the two rollers.

Knowledge

Standard

100 lines

100 lines