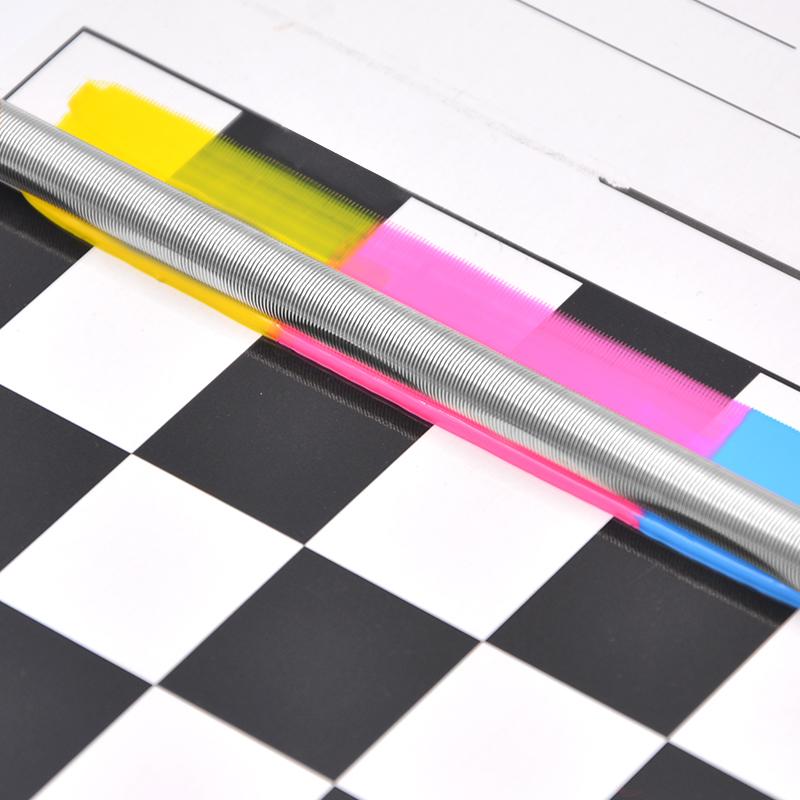

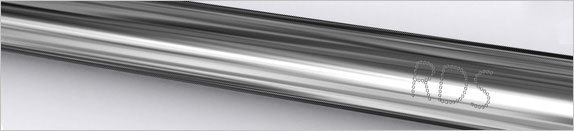

RDS 0 #3/8 "Spreader Smooth Rods film thickness is 0μm

SE9.5Mm diameter, without any wire-wound, smooth steel rod, generally installed in the machine to adjust the Film thickness size.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

RDS 0# 3/8" Applicator rod 3/8 "SPEC

RDS 0# 3/8" Applicator rod 3/8 "Details

RDS 0# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB009110

- Production process

- wire-wound

- WFT

- 0μm

- diameter

- 9.52mm

- Total length

- 400mm

- Wire diameter

- 1.14mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

0# 3/8"

Applicator rod 3/8 "

9.5Mm diameter, without any wire-wound, smooth steel rod, generally installed in the machine to adjust the Film thickness size.

The RDS 0# 3/8" coated light rod is a steel rod with a diameter of 9.5mm, and there is no steel wire winding of any diameter on the surface. It is widely used in the paper industry . RDS 0# 3/8" coated light rod is generally installed on The thickness of the coating film is regulated on the machine. RDS coating rod is made of high-grade stainless steel, which has good wear resistance and long service life.

plan

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QAre there any lines?

A

Yes, there are Smoothing Rods.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QAre all Applicator rods available for inspection in the GB/T 13217.7 standard?

A

Not necessarily, but this 0 #3/8 "Applicator rod can be considered.

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

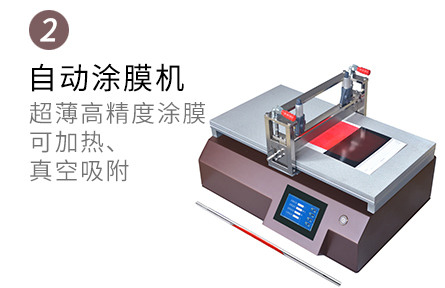

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

Knowledge

- 1Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 2One article introduces RDS Applicator rod type and FAQ

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 13217.1-2009《Test method for colour of liquid ink》