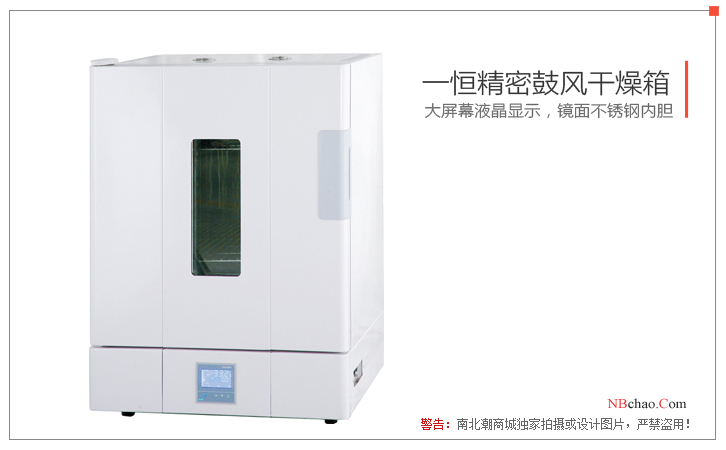

YIHENG BPG-9056A Precision Forced Air Drying Oven Input Power is 750W

SEYiHeng BPG-9056A Drying OvenSPEC

YiHeng BPG-9056A Drying OvenDetails

YiHeng BPG-9056A Drying OvenPacking list

- SKU

- NB000927

- Power

- AC 220V 50Hz

- Input Power

- 750W

- Temperature range

- RT+10~200℃

- Temperature Resolution

- 0.1℃

- Temperature Fluctuation

- ±1℃

- Temperature Uniformity

- ±2.5%

- Shelf (std.)

- 2pcs

- Interior size

- 375*370*370mm

- Volume

- 50L

- Timer

- 1~5999min

- Net Weight

- 47kg

- Gross Weight

- 78Kg

- Packing size

- 700*660*930mm

Introduction of BPG-9056A precision Forced Air Drying Oven

Yiheng BPG-9056A precision Forced Air Drying Oven is a Drying Oven with liquid crystal display, which can monitor data in real time and is convenient for observation and operation. The temperature control range of BPG-9056A precision Forced Air Drying Oven is 10~200°C, the temperature resolution is 0.1°C, and the input power is 750W.

Features

1. Humanized design

● Large-screen LCD display, multiple groups of data displayed on one screen, menu-style operation interface, easy to understand, easy to observe and operate.

● BPG-9056A precision Forced Air Drying Oven adopts mirror stainless steel liner, the four corners are semi-circular transition, and the shelf bracket can be freely loaded and unloaded, which is convenient for the cleaning work of the studio.

2. Multi-segment programmable controller (optional)

● Multi-segment LCD programmable controller, one-screen display of various parameters, and menu-style operation interface can simplify the complicated test process and truly realize automatic control and operation.

● Parameters such as multi-stage temperature, circulating wind speed, time and heating rate can be set and programmed at the same time. It can control the gradient of temperature rise, slowly rise from the initial temperature in the box, and can also preset functions such as automatic startup, standby and shutdown.

● It can be programmed with 7 sections and 63 steps, each section has 9 steps, and the setting time of each section is 1~99 hours and 59 minutes.

3. Self-diagnosis function

● When the drying box breaks down, the LCD will display the failure information, and the fault point of the operation can be seen at a glance.

4. Convenient data processing (optional)

● It can be connected to a printer, 485 communication interface or USB data transfer interface (U disk), and record temperature and time curves with a computer and printer, providing a strong guarantee for data storage and playback during the test.

5. Safety function

● The thickened design of the box wall and door ensures that the temperature of the outer surface of the box is low and protects the safety of users.

● Independent temperature limit alarm system, and sound and light alarm to remind the operator to ensure safe operation without accidents. (optional)

● High or low temperature and over-temperature alarm.

6. Good energy-saving design

● Comprehensive safety performance design prevents high energy consumption from happening.

● The sealing strip of the BPG-9056A precision blast drying box adopts a new type of synthetic silicon sealing strip, which can effectively prevent heat loss and prolong the life of the heating element. Compared with traditional equipment, the thermal power is reduced by more than 25%.

Optional

1. Multi-segment programmable temperature controller

2. Embedded printer

3. RS485 interface and communication software

4. Independent temperature limit controller

5. Wireless alarm system (SMS alarm system)

Pictures

- 1SL 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 2GB/T 9995-1997《Determination of moisture content and moisture regain of textile--Oven-drying method》

- 3GB/T 6102.1-2006《Test method for moisture regain in raw cotton by oven drying》

- 4GB/T 6978-2007《Test method for the determination of scoured yield of greasy wool - Drying oven method》

- 5GB/T 10514-2012《Determination of free water for nitrophosphate - Oven method》

- 6GB/T 24131.1-2018《Rubber, raw—Determination of volatile matter content—Part 1:Hot-mill method and oven method》

- 7GB/T 30648.5-2015《Paints and varnishes—Determination of resistance to liquids—Part 5: Temperature-gradient oven methods》

- 8SL/T 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 9GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 10GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

BPG-9056A

BPG-9056A