Leneta Form N2A-2 unsealed cardboard, top black and bottom white

SELENETA Form N2A-2 Opacity ChartSPEC

LENETA Form N2A-2 Opacity ChartDetails

LENETA Form N2A-2 Opacity ChartPacking list

- SKU

- NB000093

- Specifications and Dimensions

- 140*254mm

- Color Style

- Black and white

- type

- Surface unsealed

- Encasement Specifications

- 250 sheets

- Surface coating inks

- Gloss black ink

- Application

- Paints/inks

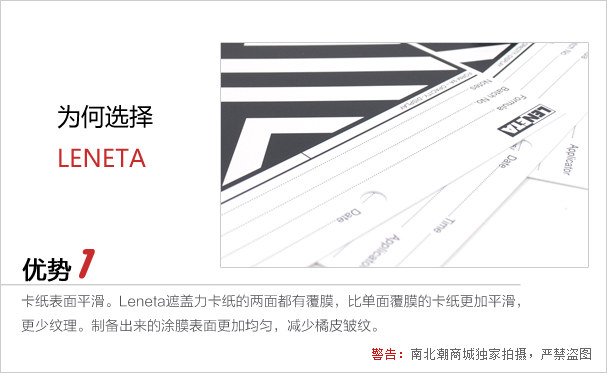

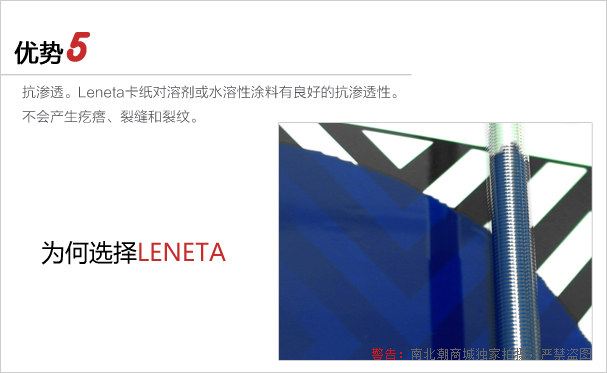

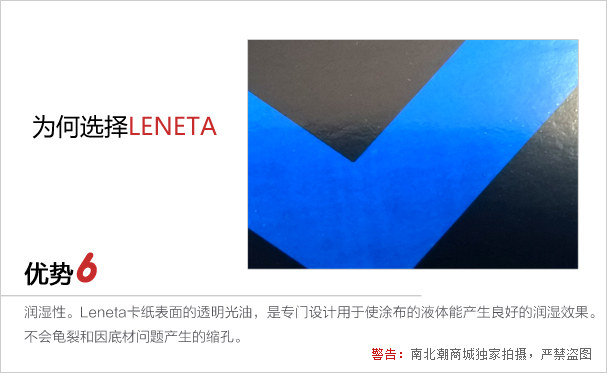

Commonly, users will choose a cover varnish on the surface when choosing a covering force paper, which can prevent the coating ink from penetrating into the jam paper, and LENETA cover varnish covering force paper has good permeation resistance. However, for cartons and other related industries, according to the characteristics of the product when conducting the hiding power test, the covering force paper without cover varnish is generally selected. Leneta Form N2A-2 Uncovered Varnish Cardboard is a black and white covering paper, with no varnish on the surface, which is suitable for carton and other industry applications.

Leneta's Seven Advantages of Concealing Power Paper

Parameters

| Model | N2A-2 | NWK |

| color | Black and white | Pure white |

| Size (mm) | 140x254 | 219x281 |

| Quantity per box (sheets) | 250 | 250 |

| standard | ASTM D 1653 | |

| Material | The surface is not covered with varnish | |

| Application | Paints/inks | |

Measurement of hiding power

The basic considerations for the sale of black and white grid paper using architectural coatings are opacity and yield, i.e., how many coats do you need to apply to a complete coating film?

How many barrels of paint are needed?

Hiding power is a measure of the ability to cover.

Hiding power (%) = Y black/Y white * 100 (%)

100% is completely covered, i.e. there is no difference between the black and white areas of the black and white cardboard.

Directions:

1. Evenly coat the paint on the covering force paper according to the coating steps.

2. After the coating film is fully dried by air, the instrument is used for objective evaluation.

3. The value of the hiding force can be measured within 1 second and displayed automatically.

The hiding power test paper is not only limited to the measurement of the hiding power of the coating, but also the corresponding hiding power test method can also be applied to the detection of the hiding rate of transparent films and plastic products.

Coverage coating rating

1. Match the coated stripes with the grooves on the anti-sagging.

2. Ignore the edges of the front and trail and look 150 mm (5-1/2 inches) in the center of the stripe, which is equivalent to the black area of the Form 7B.

3. The lowest (thickest) stripe that does not touch the stripe below is the logo stripe, and the corresponding number of grooves is the anti-sag index of the paint.

4. To get a more accurate anti-sag index, you need to add the number of grooves to the value of the increment and non-integration coefficient between the gaps (the coefficient that blends into the stripes below).

The non-integration coefficient can be estimated from the table below:

| Degree of integration | Non-integration coefficient |

| completely | 0 |

| Close to average | 0.25 |

| Less than average | 0.50 |

| More than average | 0.75 |

LENETA cardboard main types

Opacity test strips: Large patches of black and large patches of white are used to test the hiding power of the coating

Penopac Strips: Permeability and hiding tests are performed simultaneously in one table

Display: Uses a twill pattern to help show the hiding power of the coating

Opacity display: A combination of large black, large white, and twill patterns

Coating rate test strip: larger than other cards, used to measure the coating rate of coatings

Covering force paper leveling test operation

A. Equipment

1.Leneta leveler, product number LTB-2;

2. Coating leveling standard, product number LS-2;

3. Leveling test coating plate, product number DP-2;

4. Covering force cardboard Form WB for light paint, Form 7B for dark paint;

5. Padding, Form CP-2

6. Pre-cutting equipment, see page 36 of the catalog;

B. Preparation of paints

1. Stir completely and adjust the temperature to 23°C (73°F);

2. Filter and adjust viscosity if necessary;

3. Use one of the attached Pre-Shear Method descriptions to perform pre-cutting, and then test immediately.

C. Painting

1. Place the pad paper on the coating board.

2. Place the masking force paper next to the left guide edge of the coating plate.

3. The leveler is placed at the top of the cardboard, and its long arm is next to the left guide side and towards the operator.

4. Place 8-10 ml of pre-cut paint on the tip of the leveler and apply quickly and evenly at a rate of approximately 60 cm/s (2 ft/s).

5. At 23°C (73°F), keep horizontal to dry.

D. Ratings

1. After drying, cut out a 3 x 5 inch (75 x 125 mm) piece of cardboard with stripes parallel to the long side.

2. Compare it with a Leneta coated leveling standard under suitable oblique light.

3. The matching standard number is the coating leveling value of Leneta. The high level of the rating is 10 and the lowest level is 0.

E. Practical Significance of Rating Values

This is based on subjective judgment. The following table is based on the consensus of an experienced laboratory collective:

| Anti-sag index | Resistance to sagging |

| 3 4 5 6 7 8 10 12 | Very Poor Poor Poor-Fair (Poor~Fair) Fair (General) Fair-Good (Fair~Good) Good Very Good Excellent |

- 1Summary of determination methods for hiding power of coatings

- 2Hiding power/transparency measurement

- 1HG/T 3834-2006《Comparison resistance to bleeding of pigments》

- 2YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 3GB/T 13217.5-2023《Inks drying inspection method》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 7HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 8HG/T 5065-2016《Finishing varnishes for architectural coatings》

- 9GB/T 9757-2001《Solvent-thinned coatings for exterior wall》

- 10GB/T 9756-2018《Synthetic resin emulsion coatings for interior wall》

Form N2A-2

Form N2A-2