AMITTARI FG-107-50K Digital Display Force Gauge Tester 490N

SE-

Santo SHB-500 Electronic Digital Force Gauge Range 500N Graduation 0.1N$ 286.00SE

Santo SHB-500 Electronic Digital Force Gauge Range 500N Graduation 0.1N$ 286.00SE -

Small Force Gauge HF-500 Hypertherm with Built-in Sensors +/- 0.5%$ 276.00SE

Small Force Gauge HF-500 Hypertherm with Built-in Sensors +/- 0.5%$ 276.00SE -

Shandu SHB-500B digital tensile testing device maximum load 500N$ 356.00SE

Shandu SHB-500B digital tensile testing device maximum load 500N$ 356.00SE -

SUNDOO SP-500 Color Screen Display Force Gauge Range 500N Graphic Monitoring$ 433.00SE

SUNDOO SP-500 Color Screen Display Force Gauge Range 500N Graphic Monitoring$ 433.00SE -

AMITTARI FG-104-50K Digital Display Force Gauge high-precision miniature tensile Tester$ 222.00SE

AMITTARI FG-104-50K Digital Display Force Gauge high-precision miniature tensile Tester$ 222.00SE

AMITTARI FG-107-50K Digital Force GaugeSPEC

AMITTARI FG-107-50K Digital Force GaugeDetails

AMITTARI FG-107-50K Digital Force GaugePacking list

- SKU

- NB009774

- Measuring range

- ±50kgf//±490N/±110Lbf

- resolution

- 0.01kgf//0.1N/0.1Lbf

- Accuracy

- Level 0.2

- Error of indication

- ± 0.2% FS (range) ± 1 digital peak

- unit

- KgfNLbfgf

- A measurable value

- Peak, instantaneous value

- display

- Four-digit large LCD, positive dual display

- shutdown mode

- 10 minutes automatic shutdown or manual shutdown

- Allowable load

- 150% F.s (buzzer alarm when over 110% F.s)

- Data output

- USB, Bluetooth

- Power

- 2 AA batteries, or 6V DC Power

- Allowable Operating Temperature

- 0 ~ 40℃

- Allowable Relative Humidity

- <80%

- Operating Environment

- No source and corrosive medium around

- Net Weight

- 390g

- Dimensions

- 211x80x36mm

Introduction

AMITTARI FG-107 digital push-pull gauge is a small, simple, multi-functional and high-precision thrust and pull force testing instrument, which has the advantages of high precision, easy operation and portability. It also has a peak hold test mode, which is convenient for the Tester to use, and the test data can be stored and input to the computer for statistical analysis. It can be combined with various test benches and fixtures to form a testing machine for different purposes.

Features

* High precision and high resolution.

* Digital display, no parallax.

* N (Newton), kg (kilogram), lb (pound), g (gram) are available for selection and mutual conversion.

* Peak hold function. Keep peak display until manually cleared.

* Data storage function, can store 99 test values.

* Data output function, the data can be input into the computer through the data line or bluetooth for various analysis.

* Green and environmentally friendly, it can be set to automatically shut down without any operation for 10 minutes; it can also be shut down manually.

* It can be powered by alkaline batteries; it can also be powered by 6V DC power supply.

Models

| model | FG-107-1K | FG-107-2K | FG-107-5K | FG-107-10K | FG-107-20K | FG-107-50K | FG-107-100K |

| Measuring range | ±1kgf | ±2kgf | ±5kgf | ±10kgf | ±20kgf | ±50kgf | ±100kgf |

| ±1000gf | ±2000gf | ±5000gf | |||||

| ±9.8N | ±19.6N | ±49N | ±98N | ±196N | ±490N | ±980N | |

| ±2.2Lbf | ±4.4Lbf | ±11Lbf | ±22Lbf | ±44Lbf | ±110Lbf | ±220Lbf | |

| resolution | 0.001kgf | 0.001kgf | 0.001kgf | 0.001kgf | 0.01kgf | 0.01kgf | 0.01kgf |

| 1gf | 1gf | 1gf | |||||

| 0.01N | 0.01N | 0.01N | 0.01N | 0.1N | 0.1N | 0.1N | |

| 0.001Lbf | 0.001Lbf | 0.01Lbf | 0.01Lbf | 0.01Lbf | 0.1Lbf | 0.1Lbf |

Applications

Widely used in electronic appliances, construction hardware, light industry textiles, auto parts, lighters and other ignition devices, fire fighting equipment, pen making, lock making, fishing gear, chemical industry, power machinery, scientific research institutions and other industries for push-pull load, insertion and withdrawal force testing, Destructive testing, etc.

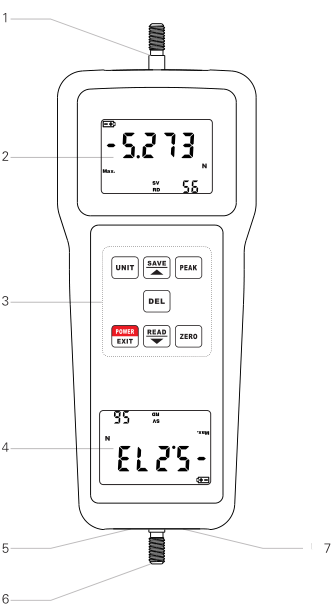

Product Structure

1. Sensing screw: It is the force-measuring and sensing structural part of the entire instrument, and its function is to transmit the push or pull force received by the tension gauge. It can be connected with tension hooks, flat probes, conical probes, V-groove probes , V-wedge probes, extended connecting rods and other accessories.

2. Display A: used to display measurement readings, measurement units, prompt information during operation, etc.

3. Operation button area: all operation buttons are distributed, and the button operation of the whole instrument is completed here.

4. Display B: used to display measurement readings, measurement units, prompt information during operation, etc. Its main role is to facilitate readings in multiple directions.

5. Data line interface: It can be connected to the specially equipped USB data line, and cooperate with the data acquisition software to realize the data acquisition function .

6. Fixing screw: The fixed structural part of the push-pull force gauge can cooperate with other components to fix the instrument.

7. Power interface: It can be connected to 6V DC power supply to realize DC power supply.

8. Fixing screw hole: The fixed structural part of the push-pull force gauge can cooperate with other components to fix the instrument.

9. Back battery box: the place where the battery is installed to realize battery power supply.

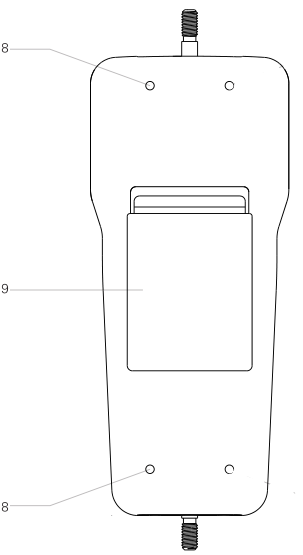

Display parameter diagram

10. Battery indicator

11. Measured value: push force (pressure) defaults to a positive value (does not display "+"); tension defaults to a negative value (displays "-")

12. Peak indicator MAX

13. Storage indicator SV

14. Read indicator RD

15. Unit of measurement

16. Number of data sets

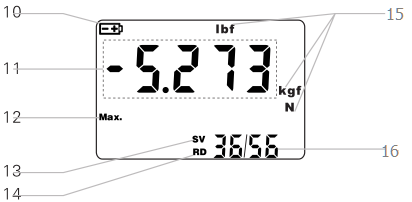

Button panel structure diagram

17. Unit key (UNIT)

18. Delete key (DEL)

19. Power/Back key (POWER/EXIT)

20. Read/minus key (READ/▼)

21. Save/add key (SAVE/▲)

22. Peak key (PEAK)

23. Zero key (ZERO)

Pictures

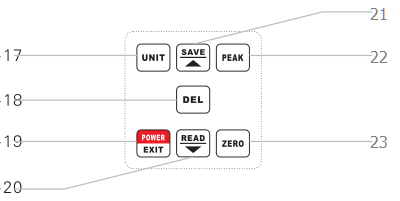

FG-107-50K

FG-107-50K