Qiwei FS-1100D Experimental Disperser (Digital Display High Speed)

SE-

Qiwei GFJ-0.7 (GFJ-750) Coating Disperser High Speed Frequency Conversion$ 655.00SE

Qiwei GFJ-0.7 (GFJ-750) Coating Disperser High Speed Frequency Conversion$ 655.00SE -

Qiwei JFS-550 High Speed Inverter Disperser 550W$ 478.00SE

Qiwei JFS-550 High Speed Inverter Disperser 550W$ 478.00SE -

MODERNER KS-370D Coating Rapid Dispersion Tester, Floor-to-Floor Bottle Clamp

MODERNER KS-370D Coating Rapid Dispersion Tester, Floor-to-Floor Bottle Clamp -

Qiwei JFS-550 high-speed frequency conversion Disperser 550W with 2.5L single-layer material bucket$ 489.00SE

Qiwei JFS-550 high-speed frequency conversion Disperser 550W with 2.5L single-layer material bucket$ 489.00SE -

Qiwei JFS-550 high-speed frequency conversion Disperser 550W with 5L Mixing Tank$ 557.00SE

Qiwei JFS-550 high-speed frequency conversion Disperser 550W with 5L Mixing Tank$ 557.00SE

QiWei FS-1100D Disperser (digital display high speed)SPEC

QiWei FS-1100D Disperser (digital display high speed)Details

QiWei FS-1100D Disperser (digital display high speed)Packing list

- SKU

- NB000984

- Motor power

- 1.1KW

- Speed regulation range

- 100~8000rpm

- Lifting stroke

- 250mm

- throughput

- 2~5kg

- Impeller diameter

- F50 / 60 / 80mm

- Power Supply

- 220V 50HZ

- Dimensions

- 450*400*800mm

- Host Weight

- 40kg

- Pillar shape

- square column

- Maximum Max. Viscosity

- 100000mPa.s

- Grinding disk diameter

- F60mm

- Timer

- No Timer function

- Barrel

- 1.5L

- Lifting method

- Double axis constant force lifting system

- motor

- Series motor

- explosion-proof

- without

- Optional

- 2.5 liter single-layer barrel, 5 liter Mixing Tank

Introduction

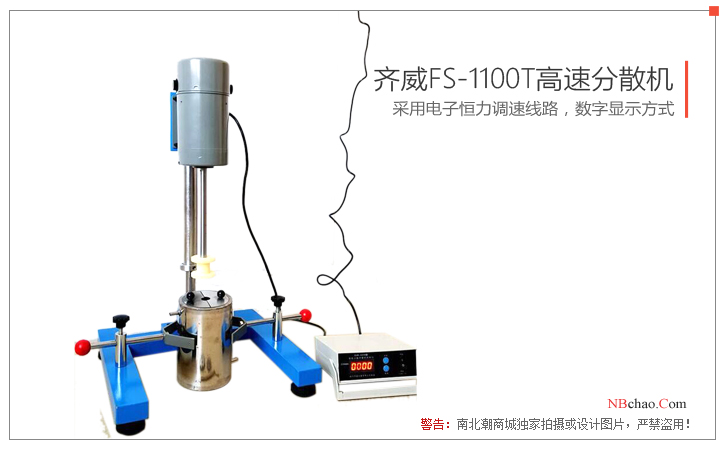

Qiwei FS-1100D dispersing machine (digital display high-speed) has a motor power of 1.1KW, which integrates dispersing and stirring functions, and completes the two processes of dispersing and homogenizing with one machine and one container. It has high efficiency, good mixing effect and easy cleaning. The feature of manual lifting is simple and convenient. FS-1100D dispersing machine is widely used in the dispersing and mixing of materials in liquids such as factories, scientific research institutions, colleges and medical institutions.

Note: FS-1100T does not have a chain, it is a cylindrical rod, and the height can be controlled by pressing directly. FS-1100D is a chain, height-adjustable, square column pole.

Principle

The disperser equipment adopts electronic constant force speed regulation circuit, the number directly displays the rotational speed of the rotating shaft, and is equipped with a dispersing impeller and a sanding disc. It can adapt to the needs of different experiments in the laboratory, and can provide correct process data for large-scale production according to the relationship between the displayed rotating shaft speed, material viscosity and chemical reaction rate.

The dispersing head of the FS-1100D disperser is driven by the motor at high speed to generate a high rotational speed in the tangential direction. Under the action of huge centrifugal force, the material produces strong hydraulic shearing and high-frequency mechanical effects, so that the fluid material can bear every minute Thousands of shearing and high-frequency mechanical effects achieve efficient mixing, dispersion, and homogeneity.

Application

FS-1100D disperser is suitable for fluid material experiments in containers.

structure function

The components of FS-1100D dispersing machine are: 1. Motor; 2. Intelligent motor speed control device; 3. Stainless steel barrel; 4. Lifting bracket; 5. Dispersing and sanding head.

Pictures

product installation

1. Put the two holders on the fixing frame, fix the stainless steel barrel, and the hole of the barrel cover coincides with the motor shaft.

2. Connect the motor to the five-pin aviation plug on the governor. (note the notch direction)

3. Connect the ground wire

Use and Maintenance Measures

1. When using, fix the selected sanding disc or dispersing impeller with the rotating shaft.

2. Adjust the high position of the rotating shaft and the capacity, lock the motor base and the container, put in the material and cover the container.

3. Turn on the power, turn on the switch, wait for the display screen to reset to zero, and then press the touch button to increase or decrease the required speed.

4. The FS-1100D dispersing machine is a series-excited motor, and sparks will be produced by the brushes when rotating, so it is not suitable for use in explosion-proof workshops.

5. It is not suitable to turn on the empty machine when the speed is greater than 4000r/min.

6. When the motor brush is less than 10mm, it should be replaced.

- 1ISO 8780-3-1990《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 3: Dispersion using a high-speed impeller mill》

- 2HG/T 5164-2017《Textile dyeing and finishing auxiliaries - Water-borne polyurethane emulsions for textile coating》

- 3GB/T 21868.4-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 4:Dispersion using a bead mill》

- 4GB/T 21868.1-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 1:Introduction》

FS-1100D

FS-1100D