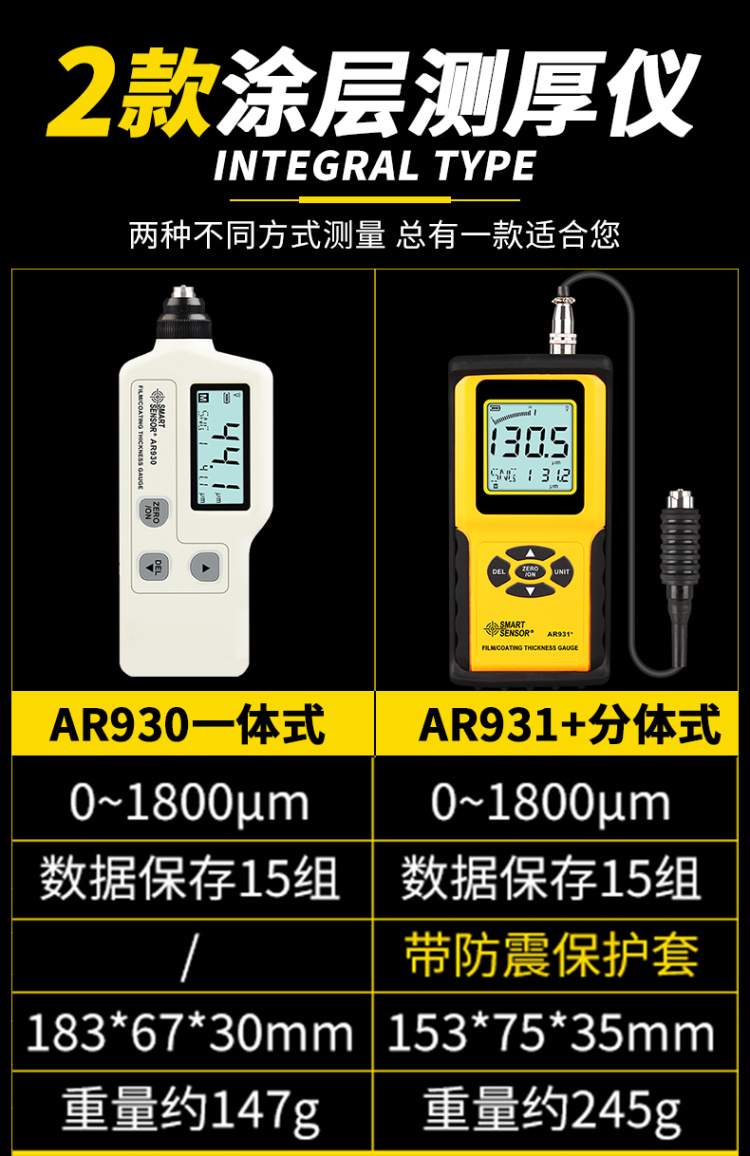

SMART SENSOR AS930 Coating Thickness Gauge magnetic Induction principle 1800μm range, integrated probe

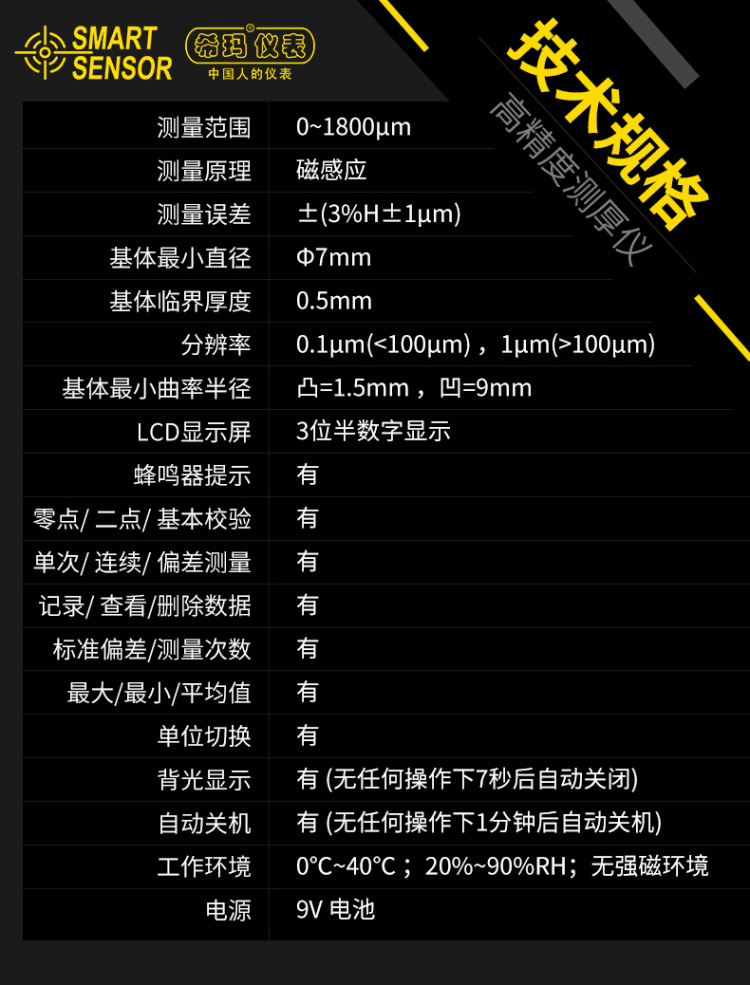

SMART SENSOR AS930 Coating Thickness GaugeSPEC

SMART SENSOR AS930 Coating Thickness GaugeDetails

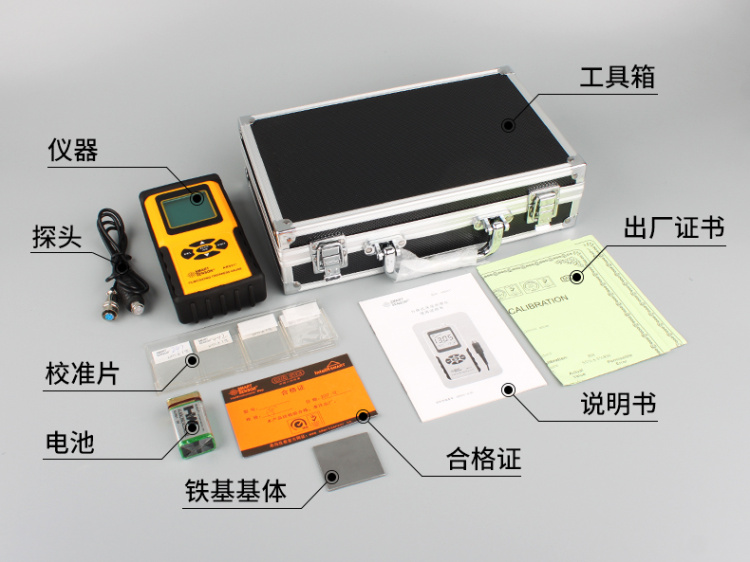

SMART SENSOR AS930 Coating Thickness GaugePacking list

- SKU

- NB009859

- Measurement principle

- magnetic Induction

- Measurement range

- 0~1800μm

- margin of error

- ±3%

- resolution

- 0.1μm|1μm

- Minimum measurement surface

- Φ7mm

- Minimum radius of curvature

- Convex 1.5mm; Concave 9mm

- thinnest substrate

- 0.5mm

- Data storage

- 15 groups

- Power Supply

- 9V battery

- Display screen

- LCD screen

- Operating temperature

- 0~40℃

- Operating temperature

- No strong magnetic environment

- Weight

- 147g

- Dimension

- 183*67*30mm

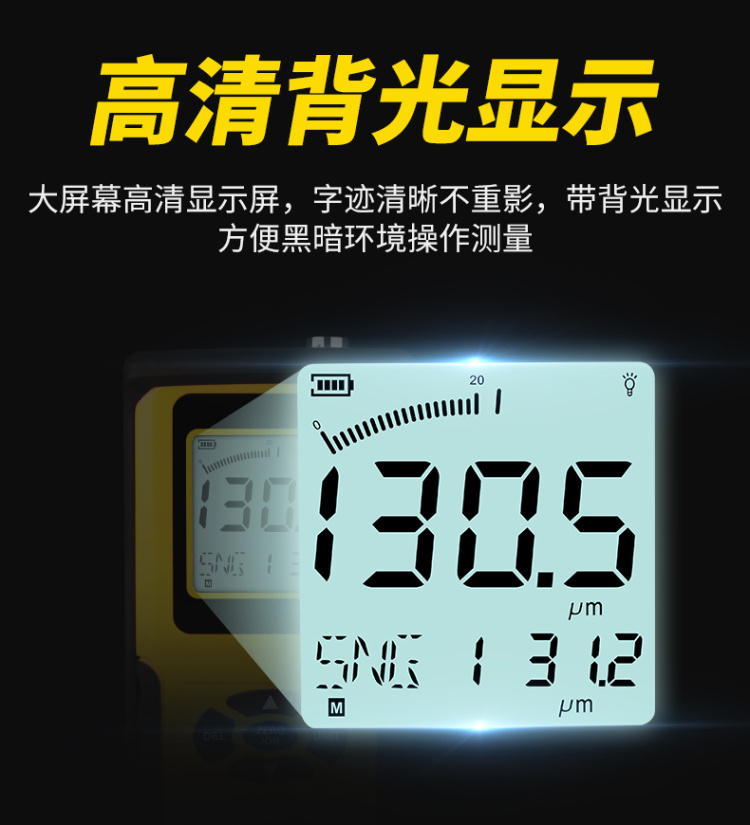

- backlit display

- Yes.

- Buzzer prompt

- Yes.

- Calibrated mode

- Zero point/two point/basic check

- statistical function

- Single measurement, continuous measurement

- Record/view measurement data

- Yes.

- statistical function

- Yes.

- Standard outer box Capacity

- 10

- Standard outer box size

- 39*32*44cm

- Standard Gross Weight

- 9.35KG

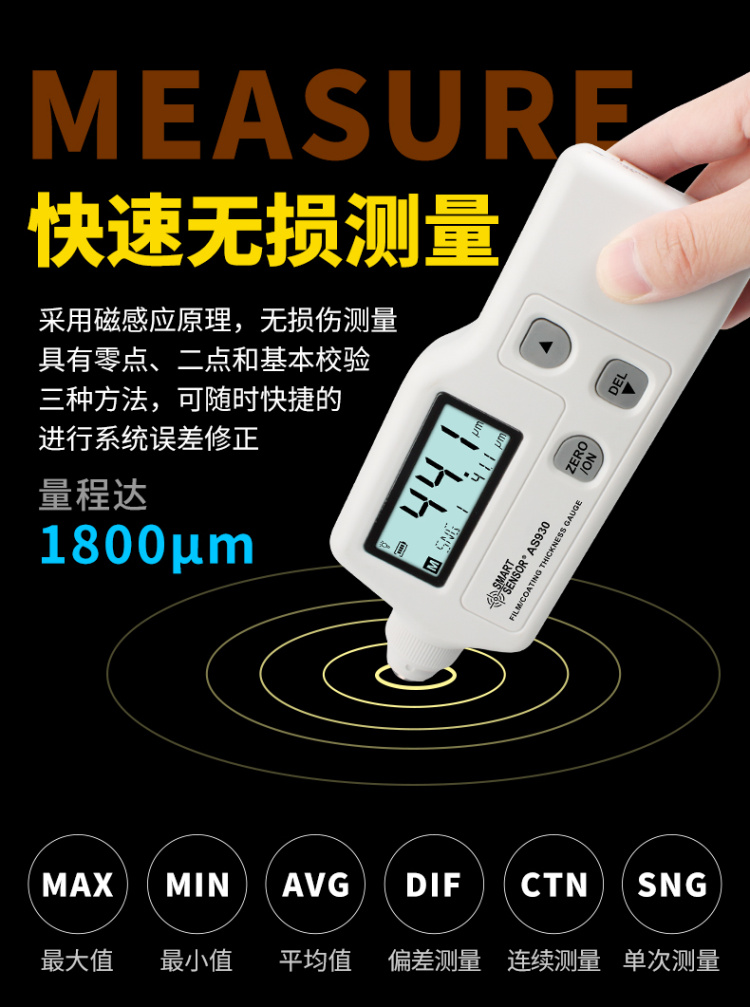

The C-MER AS930 Coating Thickness Gauge provides non-destructive measurement of magnetic metal substrates (Such as iron and hard magnetic steel, etc.)The thickness of the non-magnetic coating (e.g., aluminum, chromium, copper, enamel, rubber, paint, etc.) and the thickness of the non-conductive cladding on the non-magnetic metal matrix (e.g., copper, aluminum, zinc, tin, etc.) (e.g., enamel, rubber, paint, plastic, etc.). The coating Thickness Gauge has the characteristics of small measurement error, high reliability, good stability and easy operation, and is a testing instrument required to control and ensure product quality, and is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields.

Features

The LCD visually displays the measured value and measurement status

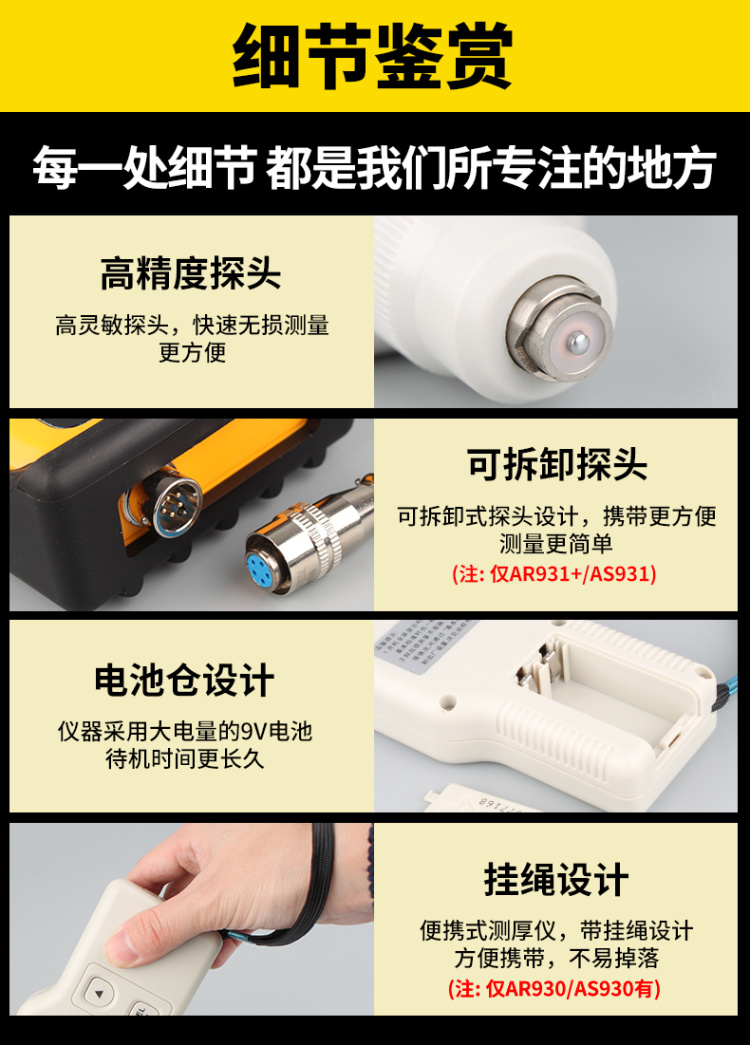

The use of high-sensitivity probes ensures accurate measurements

There are three verification methods, two points and basic, which can be carried out quickly and quickly at any timeSystematic error correction

There are three measurement methods: single and deviation

Measurement data can be recorded, stored and viewed

The sum of the measured data can be countedNumber of measurements

Buzzer prompt function

Metric to Imperial conversion function

Low power indication function

Auto-shutdown function

LCD backlight function

The design is simple and compact, making it easy to carry around

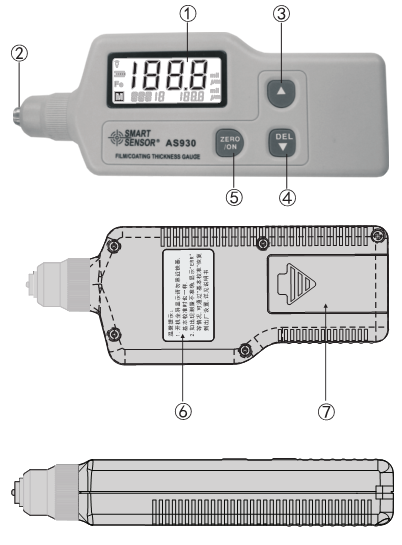

Structural description

(1) LCD screen

(2) Probe

(3) Menu Single Measurement, Continuous Measurement, Average,Maximum value Scroll up and basic calibration keys

(4) Menu (Single Measurement, Continuous Measurement, Average,Maximum) Scroll up and delete all data keys

(5) Power on/zero point calibration

(6) Simple function indication

⑦Battery door

- 1QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4SY/T 0315-2013《Technological specification of external fusion bonded epoxy coating for steel pipeline》

- 5GB/T 8923.1-2011《Visual assessment of surface cleanliness of steel surface preparation before coating - Part 1: Rust grade and treatment grade of uncoated steel surfaces and steel surfaces after full removal of the original coating》

- 6GB/T 11374-2012《Thermal spraying coating - Nondestructive methods for measurement of thickness》

AS930

AS930