SMART SENSOR AR932 Coating Thickness Gauge 0~1500a Film Thickness Gauge

-

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE -

DONGRU DR230 Coating Thickness Gauge can automatically identify ferrous or non-ferrous substrate Film Thickness Gauge$ 287.00SE

DONGRU DR230 Coating Thickness Gauge can automatically identify ferrous or non-ferrous substrate Film Thickness Gauge$ 287.00SE -

US Defelsko PosiTector 6000 FNDS1 Composite Coating Thickness Gauge measurement paints and galvanized layer thickness$ 1575.00SE

US Defelsko PosiTector 6000 FNDS1 Composite Coating Thickness Gauge measurement paints and galvanized layer thickness$ 1575.00SE -

IPRE CT300 paints film thickness Measurement Instrument magnetic Induction/eddy Current dual-use$ 373.00SE

IPRE CT300 paints film thickness Measurement Instrument magnetic Induction/eddy Current dual-use$ 373.00SE -

LEEB leeb252 Coating Thickness Gauge magnetic Induction/eddy Current dual-use automatic identification substrate

LEEB leeb252 Coating Thickness Gauge magnetic Induction/eddy Current dual-use automatic identification substrate

SMART SENSOR AR932 Coating Thickness GaugeSPEC

SMART SENSOR AR932 Coating Thickness GaugeDetails

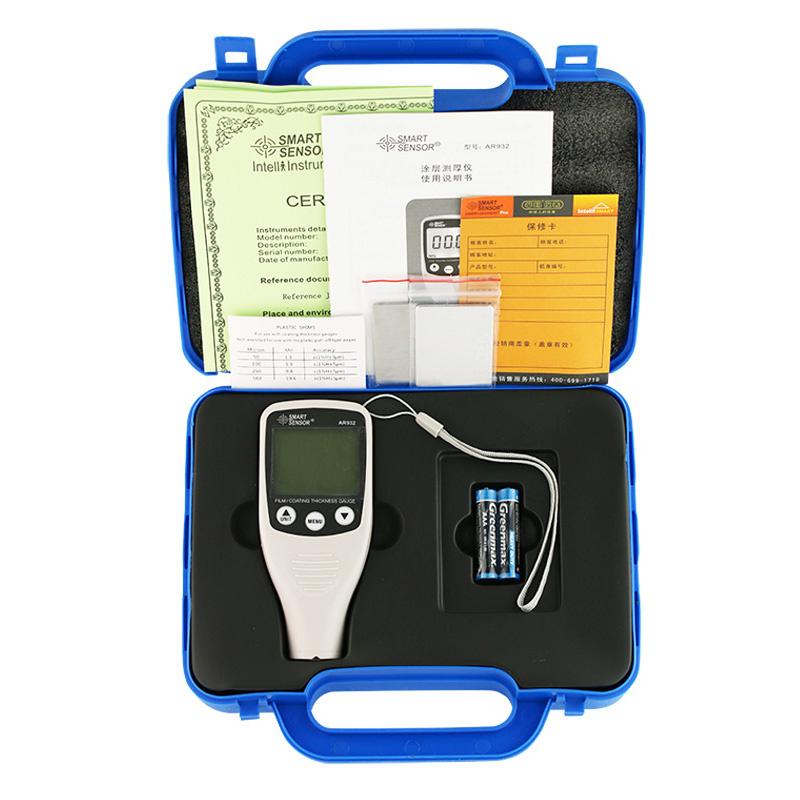

SMART SENSOR AR932 Coating Thickness GaugePacking list

- SKU

- NB009862

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1500μm

- margin of error

- ±1.8~2.2%μm

- resolution

- 0.1μm|1μm

- Minimum measurement surface

- 25*25mm

- Minimum radius of curvature

- Convex 5mm; Concave 30mm

- thinnest substrate

- 0.2mm(F);50μm(N)

- probe

- Integrated probe

- statistical function

- Max/MIN Minimum

- Data storage

- 20 groups

- Power Supply

- 2 * 1.5V AAA battery

- system language

- Chinese

- Display screen

- LCD screen with backlight

- Operating temperature

- 0~50℃

- Weight

- 75g

- Dimension

- 50*30*119mm

- Standard outer box Capacity

- 40PCS

- Standard outer box size

- 52.5*40*49cm

- Standard Gross Weight

- 20KG

- Measurement Repeatability

- ±1um(0-500um);±2um(500-1500um)

- Voltage prompt

- Low power prompt function

- Calibrated mode

- Basic calibrated, zero calibrated, Automatic calibration

- statistical function

- Single measurement, continuous measurement

- Automatic shutdown

- Yes.

- Unit display

- μm/mils

This coating Thickness Gauge adopts the principle of dual-function measurement technology, namely magnetic and eddy current thickness measurement, which can automatically identify magnetic and non-magnetic substrates, and then adopt the corresponding test methods, which can non-destructively measure magnetic metal substrates such as steel and iron. Alloys and hard magnetic rigid wires on the thickness of non-magnetic overlays such as aluminum, copper, enamel, rubber, paint, etc., and non-magnetic metal substrates such as copper. Aluminum, zinc, tin, etc., on the thickness of non-conductive overlays such as enamel, rubber, paint, and has a basic statistical function and stores 20 readings, calculating the maximum, minimum and average values.

This coating Thickness Gauge has the characteristics of small measurement error, high reliability, good stability, simple operation, etc., and is a testing instrument required to control and ensure the quality of product coating, and is widely used in the testing fields of automobile and aircraft shipbuilding, metal processing industry, chemical industry, commodity inspection and so on.

Features or Functions

Install the battery, touch the substrate, automatically turn on, and automatically shut down after 30S.

Automatically recognizes the base material and displays the corresponding base material

Extra-large LCD display

Three simple buttons for easy operation

It can be operated with one hand and has a hand-held anti-slip treatment

Convenient auto-calibration functionAutomatic calibration is performed according to 5 different calibration substrates 0/5/100/250/500

The automatic calibration function of the value can be customized according to the requirements from 0 to 1500 Um

Automatic correction function to prevent calibration misoperation

Dynamically adapt to the environment

The V-groove is suitable for measuring on cylindrical parts

The special probe structure provides better stability

An audible indication that the measurement or calibration is complete

Battery level indication

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 3HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 4GB/T 5209-1985《Paints and varnishes--Determination of resistance to water--Water immersion method》

- 5JB/T 9857-2010《General technical conditions for rock drilling machinery and pneumatic tool painting》

AR932

AR932