SMART SENSOR AR931 Coating Thickness Gauge Measurement range 0~1800a

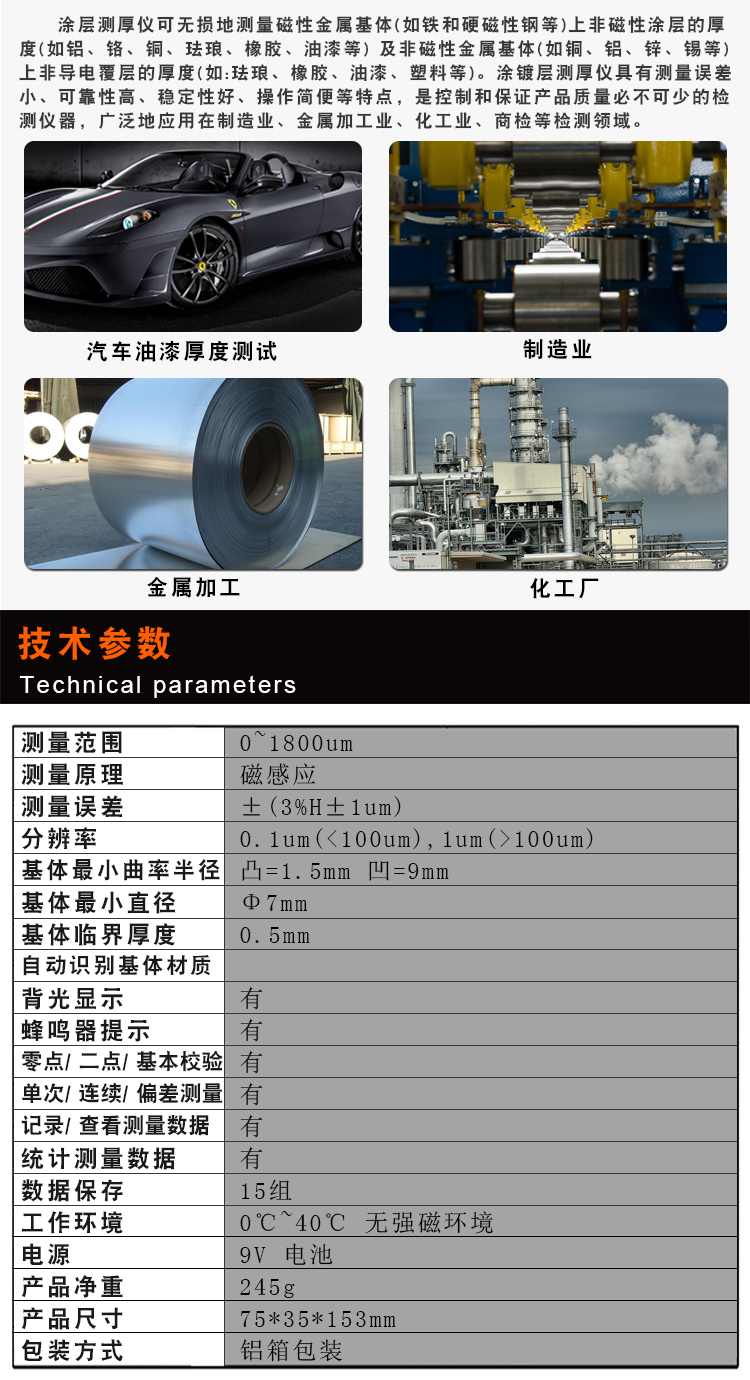

Measurement range of SMART SENSOR AR931 Coating Thickness Gauge is 0~1800um. CHINA AR931 Coating Thickness Gauge is widely used in manufacturing, metal processing, chemical industry, commodity inspection and other testing fields.

Model:

Similar products

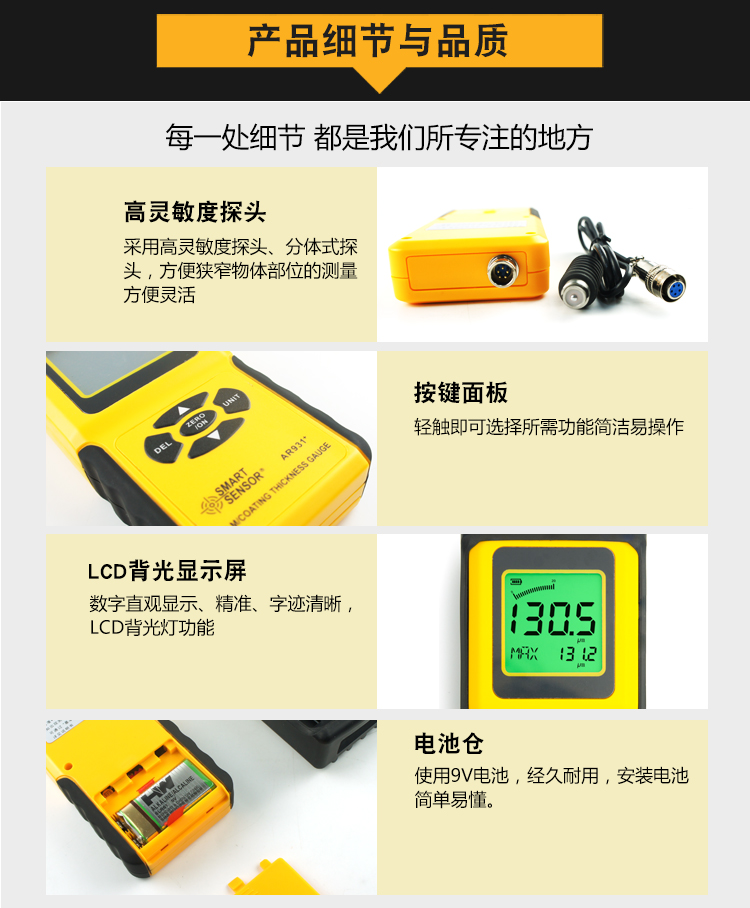

SMART SENSOR AR931 Coating Thickness GaugeSPEC

SMART SENSOR AR931 Coating Thickness GaugeDetails

SMART SENSOR AR931 Coating Thickness GaugePacking list

- SKU

- NB009863

- Measurement principle

- magnetic Induction

- Measurement range

- 0~1800μm

- margin of error

- ±3%

- resolution

- 0.1μm|1μm

- Data storage

- 15 groups

- Unit display

- μm/mils

- Voltage prompt

- Low power prompt function

- Calibrated mode

- Zero point calibrated, two point calibrated

- statistical function

- MAX Maximum, MIN Minimum, Average, Standard deviation

- statistical function

- Average/Margin Function

- Measurement mode

- Single/continuous measurement

AR931

Coating Thickness Gauge

The coating Thickness Gauge can non-destructively measure the thickness of non-magnetic coatings (such as aluminum, chromium, copper, enamel, rubber, paint, etc.) on magnetic metal substrates (such as iron and hard magnetic steel, etc.) and the thickness of non-conductive cladding (such as enamel, rubber, paint, plastic, etc.) on non-magnetic metal substrates (such as copper, aluminum, zinc, tin, etc.). The coating Thickness Gauge has the characteristics of small measurement error, high reliability, good stability and easy operation, and is a testing instrument required to control and ensure product quality, and is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields.

FAQ

QWhat is the big deviation of the data measured by this thickness gauge?

A

Hello, if the measurement data deviation is large, you can try to calibrate the thickness gauge before measurement.

Standard

AR931

AR931