SMART SENSOR AR860 Ultrasonic Thickness Gauge measurement range 1.0~300mm

SE-

SMART SENSOR AR850 + Ultrasonic Thickness Gauge measurement range 1.2-225 mm$ 235.00SE

SMART SENSOR AR850 + Ultrasonic Thickness Gauge measurement range 1.2-225 mm$ 235.00SE -

SMART SENSOR AS840 Ultrasonic Thickness Gauge Measurement Range 1.2-225 mm$ 127.00SE

SMART SENSOR AS840 Ultrasonic Thickness Gauge Measurement Range 1.2-225 mm$ 127.00SE -

SMART SENSOR AS850 Ultrasonic Thickness Gauge measurement range 1.2-225 mm$ 170.00SE

SMART SENSOR AS850 Ultrasonic Thickness Gauge measurement range 1.2-225 mm$ 170.00SE -

SMART SENSOR AS860 Ultrasonic Thickness Gauge 1.2-225 mm Range 1% accuracy$ 216.00SE

SMART SENSOR AS860 Ultrasonic Thickness Gauge 1.2-225 mm Range 1% accuracy$ 216.00SE -

LEEB322 Ultrasonic Thickness Gauge resolution 0.01mm

LEEB322 Ultrasonic Thickness Gauge resolution 0.01mm

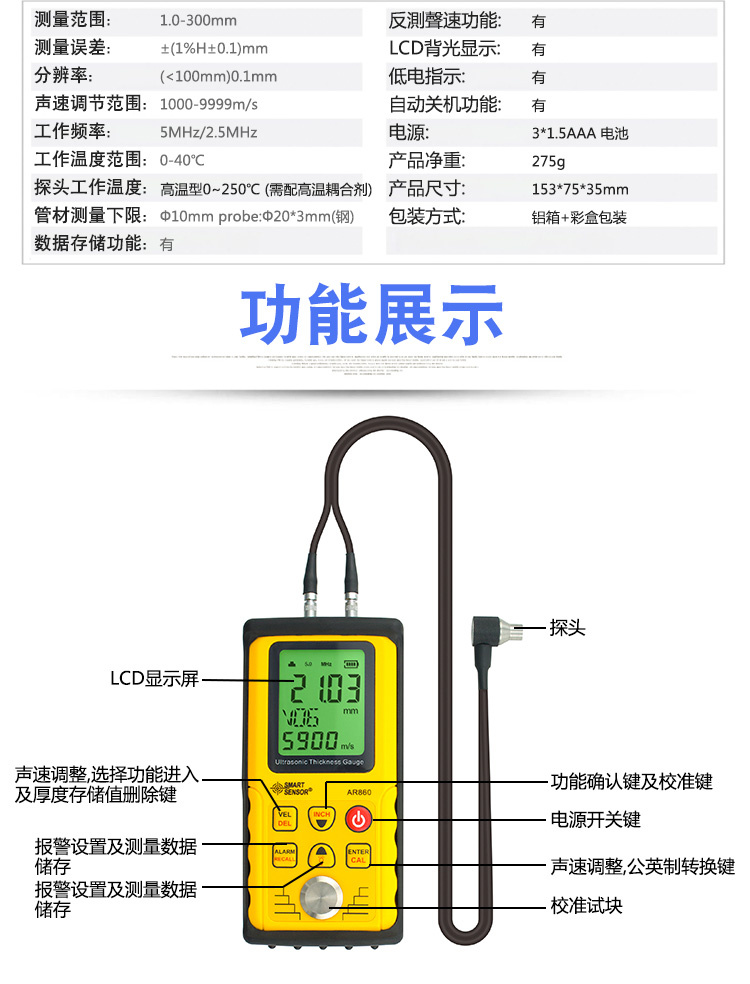

SMART SENSOR AR860 Ultrasonic Thickness GaugeSPEC

SMART SENSOR AR860 Ultrasonic Thickness GaugeDetails

SMART SENSOR AR860 Ultrasonic Thickness GaugePacking list

- SKU

- NB009865

- Measurement range

- 1.0-300mm

- Probe Frequency

- 5MHz

- Lower limit of pipe measurement

- Ф10mm probe:Ф20*3mm (verified); Ф6mm probe:Ф12*2mm (verified)

- Measurement error

- ±(1%H±0.1)mm

- Display resolution

- (<100mm)0.1mm

- Speed of sound

- 1000~9999m/s

- Speed of sound storage

- Yes.

- Display

- LCD backlight display

- Ambient Temperature

- 0-40℃

- Power

- 3 * 1.5AAA battery

- Weight

- 275g

- Probe operating temperature

- Room temperature type 0~60 ℃ High temperature type 0~250 ℃ (high temperature coupler is required)

- Speed of sound

- support

- Alarm function

- Yes.

- Low Voltage indication

- Yes.

- shutdown mode

- Yes.

- Host size

- 153*75*35mm

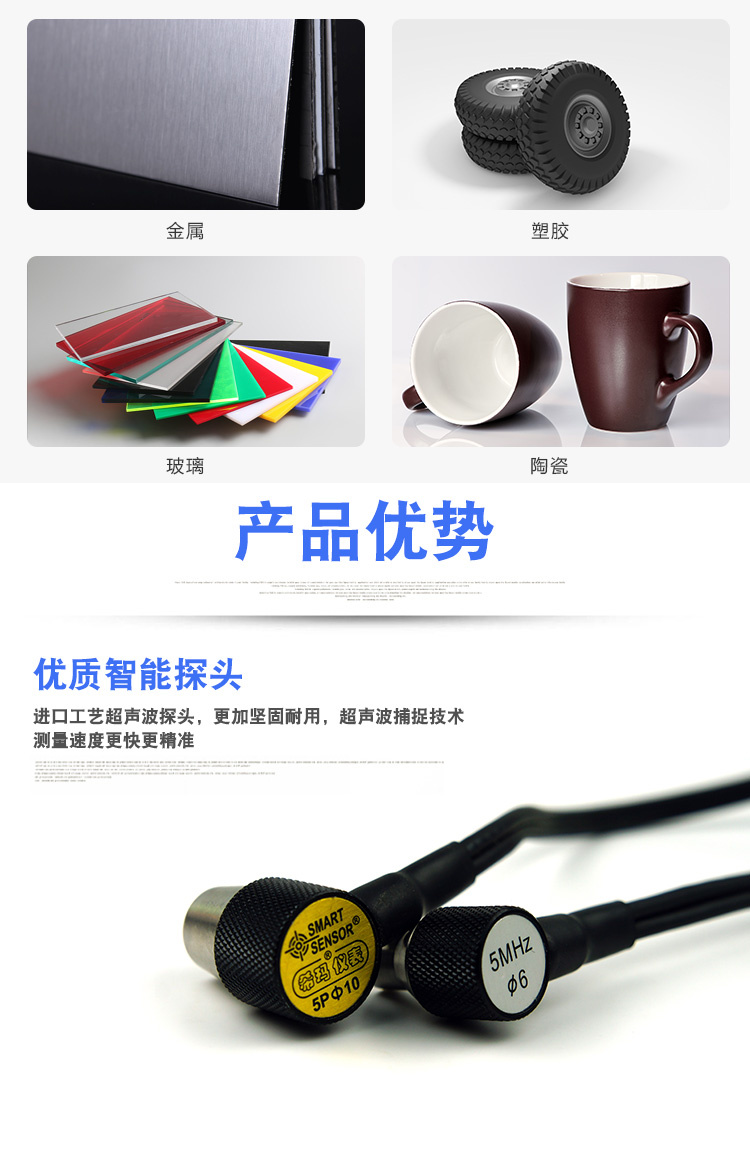

SIMA AR860 Ultrasonic Thickness Gauge adopts the principle of ultrasonic measurement and is suitable for measuring the thickness of various Accurate measurement of various processing parts, another important aspect is that it can monitor , and monitor their thinning degree after being corroded during use. It can be widely used in petroleum, Chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields.

Fundamental

The principle of ultrasonic measurement of thickness is similar to the principle of light wave measurement. The ultrasonic pulse emitted by the probe reaches the target object and propagates in the object. When it reaches the material interface, it is reflected back to the probe. It is determined by accurately measuring the propagation time of ultrasonic waves in the material . The thickness of the material to be measured.

The main function

① System error calibration function.

② The sound velocity measurement function can directly measure the sound velocity according to the actual thickness of the sample block, which can improve the accuracy of thickness measurement.

③Preset 12 kinds of sound velocity of materials, which can be adjusted and selected to facilitate measurement.

④ Coupling state prompt, wet observation of its stable state can know the coupling state.

⑤ It can store 12 thickness values, and it can be consulted and deleted.

⑥ The upper and lower limit thickness alarm setting function.

⑦ Backlight function.

⑧Battery low power indication function.

⑨ Automatic shutdown, timing automatic shutdown will save you power.

Application

Metal, plastic, pottery paste, Joanne and any other good conductors of ultrasonic waves, as long as there are two parallel surfaces above and below, the thickness can be measured with this instrument, such as steel, aluminum, copper, gold, resin, water, glycerin, etc. .Calcium iron is not suitable for using this instrument because its internal particles are too thick!

AR860

AR860