Diphenyl ether viscosity

Diphenyl ether viscosity refers to the flowability and viscosity of diphenyl ethers. Diphenyl ether is an organic compound commonly used as a solvent, catalyst and intermediate. Its viscosity affects the transport performance of liquids during reaction and separation. By adjusting the composition, temperature and rheological performance of diphenyl ethers, satisfactory flowability and catalytic effect can be achieved in different chemical processes.

Diphenyl ether viscosity Testing instrument

Diphenyl ether viscosity refers to the flowability or viscosity of an organic compound such as a diphenyl ether. It is commonly used in the chemical industry and laboratories. Test methods typically include the use of a Viscometer to measure the flowability of diphenyl ethers under specific conditions.

Diphenyl ether viscosity Application Articles

Key characteristics of inks and their impact

Inks have various characteristics, viscosity, yield value, etc. affect printing. Viscosity is related to transfer, yield value is related to flow and outlets, thixotropic transfer is shaped, drying method varies with linker, need to coordinate mass preservation.

Coating viscosity determination by Zain Viscometer method

Coating viscosity measurement by Zain Viscometer method is introduced in this paper. The instrument has simple structure, operation needs to pay attention to liquid state and temperature, and can be corrected by temperature Linear dispersion and standard oil.

Study on micromixing measurement in magnetic stirred reactor

In view of the key effect of micromixing on the rapid complex reaction, the feed concentration, Flow rate, Rotation speed, viscosity and other factors were investigated by using the iodide-iodate system.

Rotational viscometer - principle, classification, application and calibrating

This paper mainly refers to the knowledge of many parties to organize and summarize the working principle, type, different application industries and error calibrating of rotational viscometers.

Comparison and Application of Magnetic Stirring and Mechanical Stirring

Magnetic Stirrer and mechanical Stirrer have their own advantages and disadvantages, and are suitable for different experimental scenarios. Magnetic Stirrer is suitable for small-scale, low-viscosity reactions, while mechanical Stirrer is more suitable for large-scale, high-viscosity or high-volume reactions.

Determination of coating viscosity Flow Cup

In this paper, the construction of Tu-4 Viscometer and ISO flow cup, the factors affecting the accuracy of test and the calibration method are deeply analyzed.

Application of NDJ-8S digital Rotational Viscometer in viscosity measurement of cosmetic raw materials

The NDJ-8S digital rotational viscometer is a highly efficient instrument designed for viscosity measurement of cosmetic raw materials.

NDJ-5S digital Rotational Viscometer accurate measurement of natural oil viscosity

The NDJ-5S digital rotational viscometer is a high performance instrument designed for viscosity measurement of natural oils and other fluids

Application of RVDV-1H Viscometer in epoxy resin viscosity measurement

The RVDV-1H Viscometer is used to measure epoxy resin viscosity with wide range, high-precision and precise temperature control. Linear dispersion can be monitored throughout the viscosity-temperature process.

Application of NDJ-5S Viscometer in Pesticide Suspension

This paper discusses the application of NDJ-5S Viscometer in viscosity measurement of pesticide suspension, emphasizing its optimization of formulation and quality control.

Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

This article is aimed at testing the viscosity of polypropylene (PP) amide. Can NDJ Viscometer be used to measure the viscosity of polypropylene (PP) amide?

Application of SNB-1 + L0 digital swirl/spin Viscometer in Oil Industry

This paper introduces the SNB-1 + L0 digital display swirl/spin Viscometer and its application in the oil industry. SNB-1 + L0 has the advantages of efficient and fast measurement, adapting to low viscosity samples, easy operation and high Repeatability.

Application of HBDV-1H swirl/spin High Temperature Viscometer in Viscosity Determination of Plastic Particles

The HBDV-1H swirl/spin High Temperature Viscometer offers significant advantages in the field of plastic particle viscosity determination with its high-precision, wide-range measurement and intelligent operation functions. Measurement accuracy of +/- 1% FS ensures the accuracy of test results.

Rotational viscometer selection guide: How to choose the right viscosity equipment for you?

This article details the selection recommendations and Precautions for use of rotational viscometers, covering application scenarios such as laboratory, industrial production and field testing, emphasizing the importance of equipment calibrating and maintenance, helping users choose the right equipment and ensure Measurement accuracy.

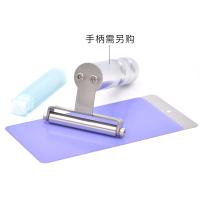

Technology and application of bar prepative template

Coating thickness can be controlled by adjusting the wire diameter and coating mixture. This method is widely used in product quality control and R & D process to ensure coating uniformity and adaptability to different substrates, suitable for a variety of painting needs.

Diphenyl ether viscosity Relevant standards

ActiveTAPPI T 254

Cupriethylenediamine disperse viscosity of pulp (falling ball method)

ActiveTAPPI T 230

Viscosity of pulp (capillary viscometer method)

ActiveASTM E2975-23

Standard Test Method for Calibration or Calibration Verification of Concentric Cylinder Rotational Viscometers

ActiveISO TS 289-4

Rubber, unvulcanized - Determinations using a shearing-disc viscometer - Part 4: Determination of the Mooney stress-relaxation rate

ActiveISO 19613

Fine ceramics (advanced ceramics, advanced technical ceramics) - Measurement of viscosity of ceramic slurry by use of a rotational viscometer

ActiveISO 2555

Plastics - Resins in the liquid state or as emulsions or dispersions - Determination of apparent viscosity using a single cylinder type rotational viscometer method

ActiveISO 12058-1

Plastics - Determination of viscosity using a falling-ball viscometer - Part 1: Inclined-tube method

ActiveISO 307

Plastics - Polyamides - Determination of viscosity number

ActiveISO 1628-2

Plastics — Determination of the viscosity of polymers in dilute solution using capillary viscometers — Part 2: Poly(vinyl chloride) resins

ActiveISO 23581

Petroleum products and related products — Determination of kinematic viscosity — Method by Stabinger type viscometer

ActiveISO 3104

Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity and calculation of dynamic viscosity

ActiveISO 1628-1

Plastics — Determination of the viscosity of polymers in dilute solution using capillary viscometers — Part 1: General principles

ActiveISO 20965

Plastics — Determination of the transient extensional viscosity of polymer melts

ActiveASTM D5125-10(2020)e1

Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups

ActiveASTM D5478-13(2022)

Standard Test Methods for Viscosity of Materials by a Falling Needle Viscometer

Diphenyl ether viscosity Instrument terminology

Diphenyl ether viscosity Testing FAQ

- How to choose the viscosity cup?

- What Viscometer Does the Cosmetics Industry Use?

- Can Viscometer measure the viscosity of paints?

- How does a rotational viscometer detect high viscosity samples?

- What is the viscosity range of Spreader liquids for laboratory coaters?

- How to calibrate Digital Viscometers?

- What is the difference between Viscometer 5s and 8s?

- Is the Viscometer accurate in measuring the protein content of yogurt?

- How to tell if a Viscometer is accurate?

- What can be used to clean kinematic viscosity meters?