Test Optical Film UV Curing Hard Coating with Pencil Hardness Tester

In recent years, various optical parts based on polyester film (PET) have been widely used due to the development of raw materials and processing technology. PET materials have excellent properties, such as good mechanical properties, heat resistance and high transparency. The efficiency and other aspects are superior to many other materials; however, due to the low surface hardness and poor wear resistance of PET materials, it is necessary to coat wear-resistant protective coatings to improve their service life. The influence of photocurable resin, reactive diluent, photoinitiator and other factors on the coating performance was studied, and a UV curable hard coating material applied to PET optical film was prepared.

Preparation of wear-resistant coatings

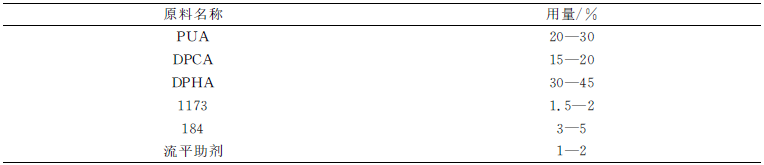

Add the photocurable resin and active monomer into the high-speed dispersion kettle according to the ratio, stir at 60°C for 30 minutes at high speed, add the measured photoinitiator and leveling aid, disperse at high speed for 10 minutes and filter for later use. The basic formula is shown in Table 1. .

Basic formulation of light-curing wear-resistant coatings

Preparation of PET hard coat

The prepared wear-resistant coating sample is evenly coated on the PET substrate by the RDS type wire Bar Coater, and the infrared leveling is performed at a temperature of 60°C for a certain period of time, and then UV curing is carried out on a UV curing machine. The thickness of the coating is 3 μm-4 μm, and a PET plus hard film is obtained.

Hardness: pencil Hardness Tester, measured according to GB/T 6739-2006;

Wear resistance: Use RCA paper tape wear Tester, load 500G, rub 1000cycles, and then measure the transmittance;

Flexibility: Measured according to GB/T1731-1993;

Adhesion: Test according to GB9286-1998;

Surface tension: measured with a dyne pen;

in conclusion

Using the UV curing reaction system, an optical film coating material with excellent physical and chemical properties is prepared, which solves the contradiction between the surface hardness and flexibility of the UV hardened coating. The experimental results show that the more suitable formula is light The amount of curing resin is 25%-30% of the system, the amount of reactive diluent is 55%-60% of the system, the ratio of DPHA to DPCA is 7:3, and the amount of photoinitiator is 5%-7% of the system. The appropriate ratio of initiator 1173 and 184 is 3:7, and the amount of leveling aid is 1.5%-1.8% of the system; the prepared coating has a hardness of 5H and an adhesion of 100%. After abrasion, there is no loss of visible light transmittance. The obtained PET coating has low surface tension, high gloss, very good flexibility and good chemical resistance.

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What performance subjects are tested for water-based floor coating materials and how do they meet the standards?