Pencil Hardness Tester tests the hardness of water-based wood coatings

Coating hardness reflects the ability of a coating to resist constant indentation, scratching, scoring and penetration by a hard object. Due to the different emphases of the testing methods, different methods will get different results when testing the hardness of the material, and each method has its own scale to determine the hardness characteristics of the material. Because of the different emphases, there is no special scale that can unify the hardness measured by different methods, but the results obtained by one method are comparable. Commonly used methods for measuring the hardness of wood coatings include pencil hardness method and pendulum hardness method. Some people also use Shore A (Shore A) hardness to compare the hardness of tough and soft thick coatings. This article mainly introduces the pencil hardness method.

The hardness measured by the pencil hardness method focuses on reflecting the coating's resistance to depression, scratching and scratching. Although some people think that the technical content of pencil hardness is very low, because of its simplicity and practicality, it can be directly measured on wood, so the pencil hardness method is still widely used in the coating industry. Before the sample preparation, the wood should be polished and cleaned. The dry film thickness of the coating should be 25-40 μm, and it should be dried for 7 days after painting. Coating film thickness and drying time affect the test results of hardness.

The test set of pencils consisted of the hardest 9H to the softest 6B. Commonly used are 4H, 3H, 2H, H, F, HB, B, 2B, 3B, 4B, 5B, 6B, a total of 12 branches. F is the intermediate hardness level, "H" means "hardness", and "B" means "blackness". The hardness of a pencil is determined by the ratio of graphite and clay used in making the lead. The more graphite, the darker and softer the lead. The more clay, the harder the lead. The hardness number of the pencil is used to indicate the hardness of the coating film.

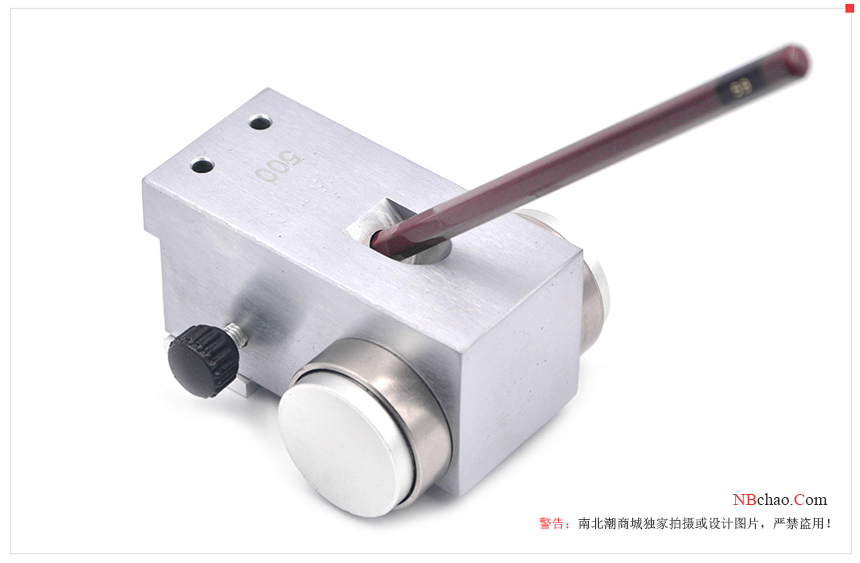

To test the pencil, cut off the wooden pole to expose a lead core about 3mm long. The pencil is drawn vertically on the sandpaper to make a flat surface, and the edge should be sharp. Hold the pencil so that it is at an angle of 45° to the paint surface to be tested, apply pressure, and push the pencil lead forward on the paint surface. The pencil of each hardness is measured on the sample 5 times, each time with a new lead with sharp edges, find out the number of the pencil that scratches or scratches the coating film at least 2 times in the 5 tests, and then use a softer pencil No. pencil test, if no more than one scratch or scratch is obtained, set the latter pencil No. as the hardness of the coating. In order to eliminate the deviation caused by uneven force and inaccurate angle of holding a pencil, various pencil Hardness Testers have been launched on the market.

The range of differences between the pencil hardness grades is relatively large, which cannot reflect the small hardness difference between the coating films. That is to say, the actual softness and hardness of the coating films with the same pencil hardness may be significantly different. However, the pencil hardness comprehensively considers the anti-sag and anti-scratch properties of the coating, which has great practicability.

The pencil hardness test method of the coating film can refer to the Chinese standard GB/T 6739-2006 "Determination of coating film hardness by pencil method for paints and varnishes" and the American standard ASTM D 3363-05 "Standard Test Method for Film Hardnees by Pencil Test".

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What performance subjects are tested for water-based floor coating materials and how do they meet the standards?