How does the pencil Hardness Tester test the hardness of coated insulating glass?

The film hardness of the coated insulating glass is an important content of the physical properties of the coated glass. Hardness generally refers to the ability of a certain part of a material to resist other hard objects pressing into its surface. Generally speaking, when foreign objects invade the part of the coated glass film layer, the stronger the resistance of the coated glass film layer, the greater the hardness of the coated glass film layer. During the use of the coated heat-insulating glass film, it is also possible to be touched, rubbed, scratched, scratched, etc. by external objects. Therefore, the greater the hardness of the coated heat insulating glass film layer, the better the self-protection ability will be shown during use, and the longer the service life will be.

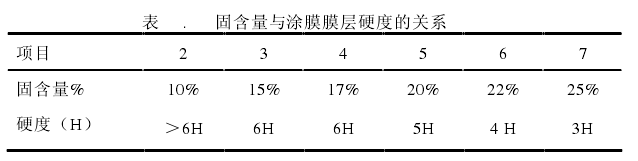

Use a pencil Hardness Tester to test the hardness of the film layer of the coated glass, and compare it to the standard stipulated in "GB/T6739-1996 Coating Film Hardness Test Method". The test results (as shown in Table 3-4) show that the solid content of ATO has a great influence on the film hardness of the coated glass during the process of synthesizing the coating. The higher the solid content, the lower the hardness of the coating. When the solid content is 17%, the hardness of the film layer reaches 6H, and when the solid content is between 20-25%, the hardness of the film layer is between 3-5H.

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What performance subjects are tested for water-based floor coating materials and how do they meet the standards?