Xenon lamp aging Test Chamber: test the light resistance of ink materials

Xenon arc weathering chambers are R&D and quality control tools for testing materials exposed to direct sunlight, sunlight through window glass, or indoor lighting.

Xenon short-arc lamps have a blue-white spectrum and very high UV output.

These lamps are primarily used for UV curing applications, object disinfection and ozone generation.

In this article, we will use the xenon accelerated lightfastness test to test the lightfastness of inks and discuss the correlation between the xenon accelerated lightfastness test and the natural exposure test of the ink.

As a kind of transportation packaging, colored corrugated boxes will inevitably be exposed to the natural environment for a long time.

If the ink printed on its surface has poor light resistance, it will directly affect its appearance.

In order to ensure that colored corrugated boxes produce good color effects over a long period of time, lightfastness testing of inks is required.

Outdoor Aging Factors

Outdoor aging is mainly related to three factors: light, temperature and humidity.

Any one of these factors can cause ink aging, and the combination of the three will cause a greater degree of aging.

1. light

The chemical bonding of polymers is sensitive to different wavelengths of light in sunlight, and short-wavelength ultraviolet rays are the main reason for the aging of most polymer physical properties.

However, for some printing materials and inks, in addition to short-wavelength ultraviolet light, long-wavelength ultraviolet light or even visible light can also affect it, resulting in discoloration or fading.

2. Temperature

Aging is a photochemical reaction, and although temperature does not affect the speed of photochemical reactions, it does affect the speed of subsequent chemical reactions.

Therefore, the effect of temperature on ink aging is non-linear.

3. Humidity

Water directly participates in the aging reaction of ink.

Studies have shown that outdoor materials are exposed to moisture for a long time (up to 8-12 hours per day on average), and dew is the main cause of moisture in outdoor materials.

Xenon lamp accelerated light fastness test principle

1. Sun simulation

As the light source of the xenon lamp aging Test Chamber, the xenon lamp produces ultraviolet, visible light and infrared rays, which can well simulate the full spectrum of sunlight.

The spectrum generated by the xenon lamp needs to be filtered to reduce unwanted UV light before performing accelerated photostability testing.

Different types of filters are used to provide different spectra, especially short UV bands with different cut-off points, which will greatly affect the aging speed of the ink.

The choice of filter depends on the test material and the end-use conditions of the product, but generally three types of filters are used: daylight filters, window glass filters, and extended UV filters.

In the xenon accelerated light fastness test, the window glass filter is generally used.

2. Irradiance Control

The new xenon Test Chamber is equipped with an irradiance control system, and the xenon aging chamber is equipped with a closed-loop solar eye control system to provide more consistent light intensity.

The control of irradiance is very important in the xenon lamp test system.

The spectral range of xenon lamps is generally 295-3000nm, and the new standard requires that the control of light intensity should be based on point control (such as ISO 11341-2004, ASTM G155-05a, ISO 4892-2:2003, etc.). ) and the selection of control points is based on the simulated environment and the physical properties of the test materials and products.

For outdoor environments, 340nm is generally used.

3. Temperature control

Temperature is a direct factor affecting the aging speed of ink, so the temperature of the xenon lamp Tester needs to be strictly controlled.

Xenon Test Chambers are typically used to precisely control the surface temperature of a test sample using a black panel or black standard thermometer.

ISO international standards mostly use black panel thermometers, while some American standards use black panel thermometers.

Some xenon Test Chambers can also control the air temperature in the chamber at the same time, so as to realize the overall control of the exposure environment temperature.

4. Humidity simulation

Generally, the xenon lamp aging Test Chamber simulates the influence of humidity on ink through water spray or humidity control system.

Among them, water spray is used to simulate the thermal shock and stress corrosion of rainwater on outdoor colored corrugated boxes; the humidity control system is used to control the relative humidity during the test.

Xenon Arc Accelerated Lightfastness Test

1. Test conditions

Using the test conditions in the GB/T 22771-2008 standard, the xenon lamp accelerated light fastness test was carried out on 11 different ink samples.

The specific test conditions of the xenon lamp test are shown in Table 1

| Laboratory | Xenon lamp aging Test Chamber |

| Test Conditions | 11 different ink samples named: Sample 1, Sample 2,...Sample 11 |

| standard test | GB/T 22771-2008 |

| radioactivity | 1.10W/㎡@420nm |

| filter | window filter |

| black standard temperature | 50℃ |

| indoor air temperature | 44°C |

| Relative humidity | 50% |

| testing time | 5 hours (Phase 1) 10 hours (Phase 2) 15 hours (Phase 3) 20 hours (Phase 4) 30 hours (Phase 5) 40 hours (Phase 6) |

2. Test results

Measure the color difference of the ink samples before and after the test using the instrument measurement method (using D65 light source, 10° viewing angle)

The test results are shown in Table 2.

3. Results Analysis

Before the xenon-accelerated lightfastness test, we already know that some of the 11 ink samples have good lightfastness, some have average lightfastness, and some have poor lightfastness, with great differences.

The test results confirm this and demonstrate that different lightfastness levels of the ink samples can be differentiated using the xenon arc Tester.

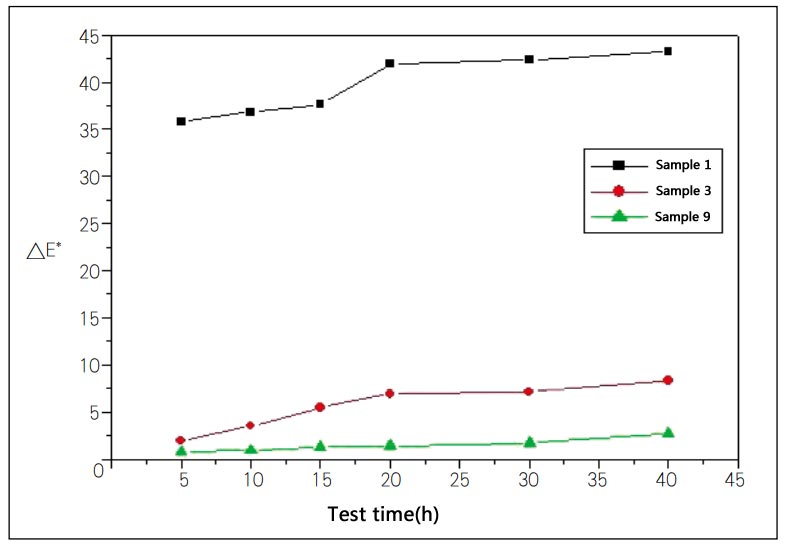

As shown in Table 2, sample 9 has better light fastness, sample 3 has average light fastness, and sample 1 has poor light fastness.

The changes of these three ink samples at different test stages are shown in Fig. 1

Xenon Arc Accelerated Lightfastness Test Results

Schematic diagram of ΔE changes of sample 1, sample 3, and sample 9 at different test stages

Test Procedures and Results of Natural Exposure Tests

In addition to xenon-accelerated lightfastness testing, ink samples were also tested for natural exposure.

Eleven ink samples were placed next to a window pane near the factory warehouse to simulate the harsher conditions the ink samples would encounter in real-world applications.

The test results are shown in Table 3.

Natural Exposure Test Results

Correlation Between Xenon Accelerated Lightfastness Test and Natural Exposure Test

Table 2 and Table 3 respectively show the color difference ΔE* of the xenon accelerated lightfastness test and the natural exposure test of 11 ink samples before and after the test.

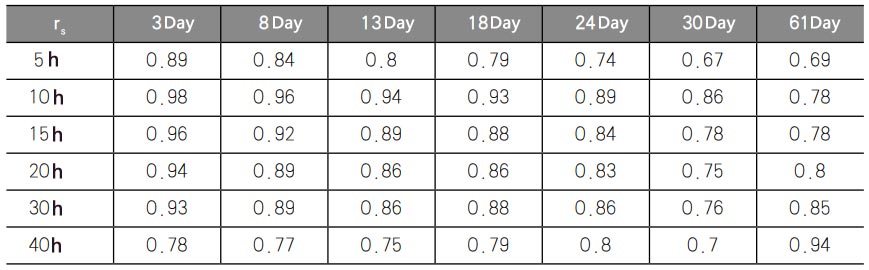

Correlation coefficients (rs) between xenon-accelerated lightfastness tests and natural exposure tests at different test stages were calculated (see Table 4).

The correlation coefficient refers to the correlation of test results obtained when testing the same set of ink samples using two different test methods.

The calculation formula of the correlation coefficient rs is rs = 1-6∑di 2 / [n(n2 – 1)], where n represents the number of ink samples, and di represents the difference of each row of data in the two columns.

The closer rs is to 1, the better the correlation between xenon accelerated lightfastness test and natural exposure test.

It can be seen from Table 4 that the correlation coefficients of the xenon accelerated light fastness test and the natural exposure test are greater than 0.70 in all test stages, which has a good correlation.

The correlation coefficient between the 10-hour xenon accelerated light fastness test and the 3-day natural exposure test is as high as 0.98.

From the results in Tables 2 and 3, it can be seen that the color difference between the 61-day natural exposure test and the 40-hour xenon accelerated lightfastness test is not as large as the color difference between the ink samples.

Based on the color difference of the ink sample after 61 days of natural exposure, we converted the time required for each ink sample to achieve the same color difference in the xenon accelerated lightfastness test, and then took the arithmetic mean

The end result is:

29 hours of xenon lamp accelerated light resistance test is equivalent to the effect of 61 days of natural exposure test.

This means that xenon accelerated lightfastness testing is 50 times faster than natural exposure testing.

Of course, this multiplier only applies to the 11 ink samples studied in this paper and may not apply to other ink samples or other packaging materials.

- 1Basic Principle, Functional Characteristics and Application of xenon arc aging Test Chamber

- 2Introduction of working principle and application scope of water-cooled xenon arc weathering Test Chamber

- 3The difference between fluorescent UV Lamp and xenon arc: Two Light sources in artificial accelerated aging

- 4Xenon arc weathering vs UV weathering: differences in ray of light simulation

- 5Rubber aging talk: xenon arc aging, ultraviolet light aging, ozone aging

- 6Xenon arc aging Test Chamber common faults and solutions, how to maintain?

- 7Application of xenon arc aging Test Chamber in coil coatings

- 8Application of xenon arc weathering Test Chamber in sealing parts

- 9Application of xenon arc weathering box in gluing agent