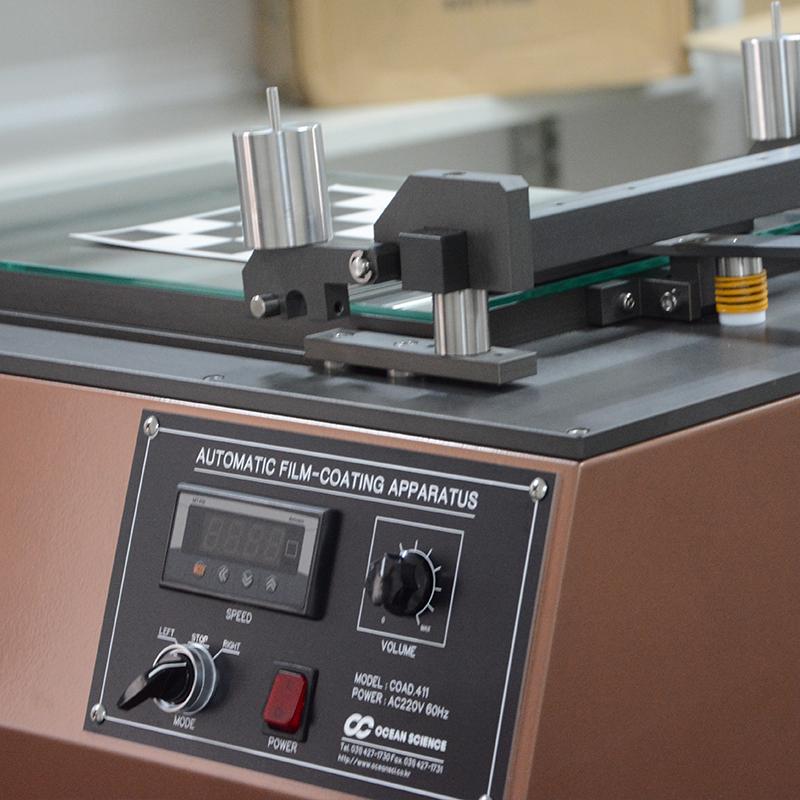

Automatic Film Applicator 411a (Drawdown Vacuum Plate + Heating Plate) OCEAN SCIENCE baseplate with heating function and adjustable temperature

-

China Heating Automatic Film Applicator TBJ-A2-XB Glue Coater bar type, with imported bar$ 1951.00SE

China Heating Automatic Film Applicator TBJ-A2-XB Glue Coater bar type, with imported bar$ 1951.00SE -

China Vacuum chuck bar heating film instrument hot-melt adhesive coater TBJ-X4-XB with imported bar$ 3360.00SE

China Vacuum chuck bar heating film instrument hot-melt adhesive coater TBJ-X4-XB with imported bar$ 3360.00SE -

China TBJ-A2 Heating Wire Rod Lab Film Applicator with Heating Scraping Machine$ 1794.00SE

China TBJ-A2 Heating Wire Rod Lab Film Applicator with Heating Scraping Machine$ 1794.00SE

OCEANSCIENCE 411A (Drawdown Vacuum Plate + heating plate) Automatic Film ApplicatorSPEC

OCEANSCIENCE 411A (Drawdown Vacuum Plate + heating plate) Automatic Film ApplicatorDetails

OCEANSCIENCE 411A (Drawdown Vacuum Plate + heating plate) Automatic Film ApplicatorPacking list

- SKU

- NB001225

- Coating method

- Wire Rod Coating

- Coating size

- 300*450mm

- Application width

- 300mm

- Spreader trip

- 330mm

- Coating speed

- 10~100mm/s

- Weight application

- 2*500g

- Pore specification

- φ 1mm, 20x20mm, with vacuum pump

- Heating Temperature range

- RT+~150℃

Introduction

OCEAN SCIENCE Automatic Coating Machine 411a (Vacuum Plate + Heating Plate) is a fully automatic coating machine imported from South Korea, with vacuum adsorption plate and Heating Plate, to achieve the heating function of the bottom plate, and the vacuum plate fixes the substrate well, which can adjust the temperature of the bottom plate during the coating process.The automatic coating machine is a special coating equipment that evenly coats a layer on film, paper, cardboard and other substrates through liquid objects such as paints, paints, inks, adhesives, polymers, etc., and can test the performance of the coating after drying. The automatic coating machine has a constant speed and uniform pressure application, and is capable of stable coating tests.

Product Operation

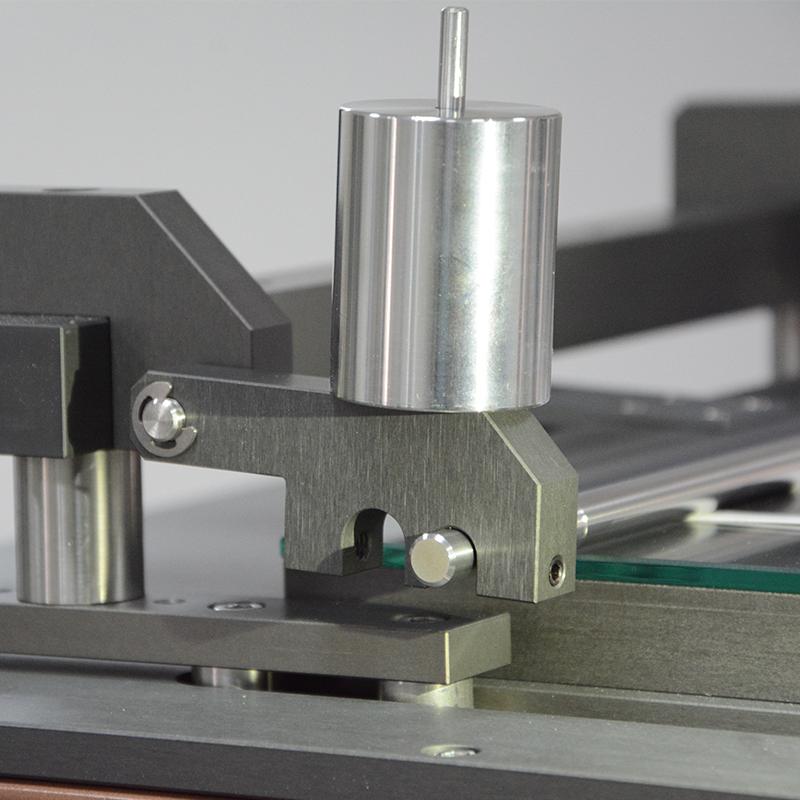

1. Place the substrate flat on the top of the coating plate and fix it with a fixing fixture.

2. Install the coating rod for the test to its fixture and fix it.

3. Open the speed button and adjust to the desired speed.

4. After the setting is completed, the coating solution is evenly and appropriately applied to the starting position of the substrate and the coating rod. Turn on the start button to perform the coating test. When the coating is completed, the wire rod is in the stop position and does not move, so as to prevent repeated testing results from affecting the test results.

5. After the test is completed, the coated substrate will be dried and related tests. This product is disassembled and cleaned in time.

Precautions for use

1)411aAutomatic coating machine Rest on a stable, level platform.

2) Try to use the dropper to configure the position and appropriate amount of the coating solution to avoid splashing the coating solution and affecting the use of the equipment.

3) After use, please do not rotate when the coating rod returns to its original position to avoid affecting the life of the coating rod.

4) Attention411aAutomatic coating machine Check the power supply and start-up, clean and manage after use.

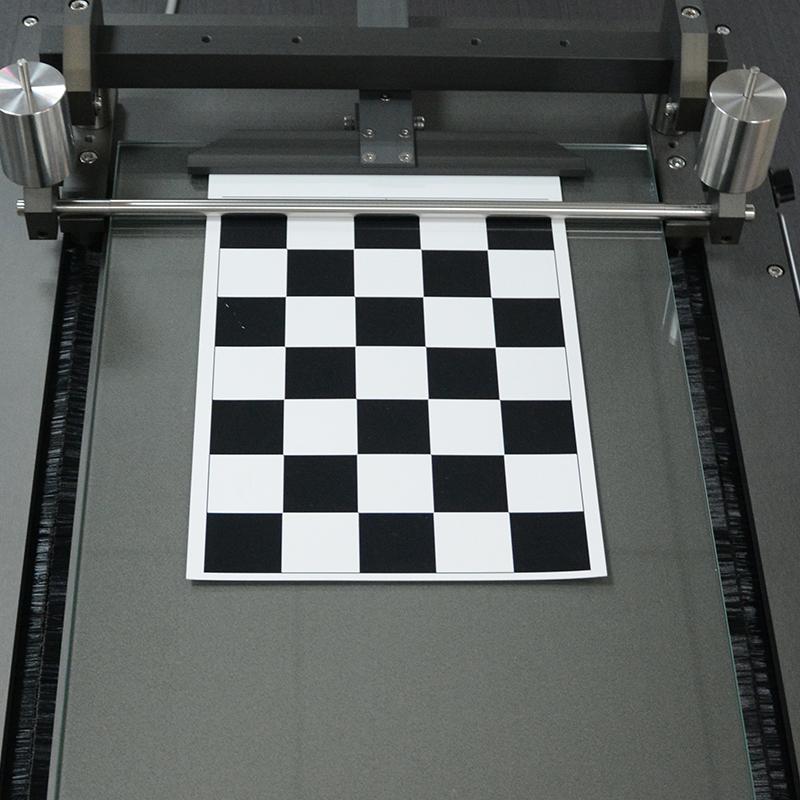

Actual picture of the product

Optional

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2HG/T 3355-2003《Various colour nitrocellulose primer》

- 3HG/T 4914-2016《Over laminated pressure sensitive adhesive tape》

- 4GB/T 9756-2018《Synthetic resin emulsion coatings for interior wall》

- 5ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

- 6GB/T 9756-1995《Synthetic resin emulsion coatings for interior wall》

411A (Drawdown Vacuum Plate + heating plate)

411A (Drawdown Vacuum Plate + heating plate)