Elcometer Elcometer 307 Ultrasonic precision Thickness GaugeSPEC

Elcometer Elcometer 307 Ultrasonic precision Thickness GaugeDetails

Elcometer Elcometer 307 Ultrasonic precision Thickness GaugePacking list

- SKU

- NB001633

- Measurement range

- Interface echo (IE): 1.65~ 25.40mm; Echo echo (EE): 0.15~ 10.15mm; Plastic mode (PLAS): 0.15~ 5.00mm

- Probe style

- Split probe

- Probe Frequency

- 15MHz single crystal

- Measurement error 1

- Interface echo (IE ): +/- 0.015mm (1.65-2 ); +/- 0.5% (3.00-25); Echo (EE ): +/- 0.015mm (0.15-2 ); +/- 0.5% (3.00-10);

- Display resolution

- 0.1/0.01mm

- Measurement mode

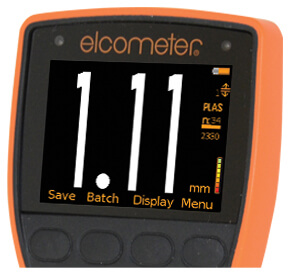

- Interface Echo (IE), Echo Echo (EE), Plastic Mode (PLAS)

- Data storage

- 100,000 readings in 1000 alphanumeric data set

- statistical function

- Number of readings (n), mean (average) (x), standard deviation (sigma), lowest reading (Lo), highest reading (Hi), coefficient of variation (CV%)

- Operating language

- Chinese, English, French, German

- Display

- LCD screen

- Application Software

- Yes.

- Host size

- 145*73*37mm

- Weight

- 210G (7.4oz) - Battery included, Sensors not included

- Power Supply

- 2 * 5 AA battery

- Measurement speed

- 4, 8 & 16Hz (4, 8 & 16 readings per second)

- Environmental temperature

- -10~50℃

- Interface

- USB、Bluetooth

- Operating Time

- Alkaline battery: about 15h; lithium battery: about 28h

- Measurement error 2

- Plastic mode (PLAS ): +/- 0.015mm (0.15-2 ); +/- 0.5% (3.00-5)

The new Elcometer 307 Ultrasonic Precision Thickness Gauge is designed to provide accurate measurements of thin materials.

Highly accurate measurement of thin materials

The new Elcometer 307 is flexible, easy to use with ±1% accuracy, measuring from 0.15mm (0.006") to 25.40mm (1.000") across three measurement modes; Interface Echo (IE), Echo Echo (EE) and Plastic Mode (PLAS).

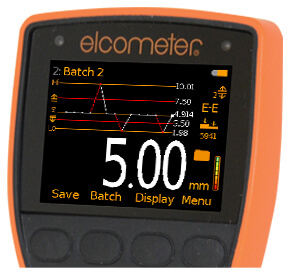

Select and customize the reading display

The new Elcometer 307 has a display mode selection that allows users to choose the one that suits their needs; Readings, Selected Statistics, Histograms, Trend Charts, or Difference Patterns.

User-defined limit pass/fail indication

Limits can be set on a new Elcometer 307 for individual readings or for each batch with a visual pass/fail warning.

Each measurement is stored for further analysis

Up to 100,000 readings can be saved to the instrument store as per measurement, which can later be downloaded to the inspection app or ElcoMaster® for further analysis and reporting.

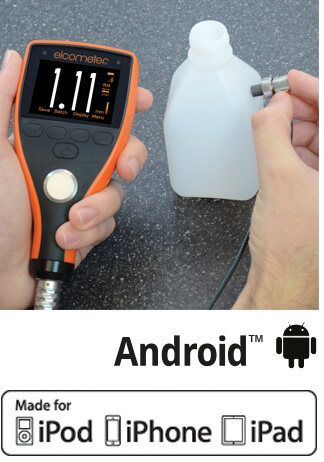

Data output to a computer, Android or iOS mobile device

Connect your new Elcometer 307 to a computer, Android or iOS mobile device via Bluetooth®, Bluetooth or USB, download data to an inspection app or access ElcoMaster® to generate reports instantly.

Key features of the Elcometer 307 Ultrasonic Precision Thickness Gauge include:

The high-low limit indicators provide an indication of the problem area

The high-low limit indicators provide an indication of the problem area

2-point, 1-point, material, velocity, thickness settings with factory calibration options allow for accurate measurement of a wide range of materials

Up to 3 programmable calibration memories allow the user to select a saved calibration method without having to recalibrate the instrument

4, 8, 16Hz selectable measurement rate (4, 8, 16 readings per second)

In 16Hz scan mode, it is used to measure large surfaces

Up to 100,000 readings can be stored, and up to 1,000 sequential batches can be used for further analysis and downloaded to a PC or mobile device

USB and Bluetooth® data output to an ElcoMaster® PC or ElcoMaster® mobile app to generate reports instantly

Comes with an auto-identification smart sensor to ensure correct probe identification when the sensor is changed. The Elcometer 307 is available with or without a 15MHz 1/4" Spiral Right Angle Single Element Thickness Sensor. Click here for a full list of sensors.

Features | |

Easy-to-use multilingual menu structure | ■ |

| Strong, impact-resistant, waterproof, dustproof; Equivalent to IP54 | ■ |

| bright color screen; With automatic or manual brightness adjustment | ■ |

| Scratch and solvent resistant displays; 2.4" (6cm) TFT | ■ |

Large feedback button | ■ |

Powered via USB from a computer | ■ |

| Update instrument software via ElcoMaster® Software 1 | ■ |

Data output | |

USB; to the computer | ■ |

Bluetooth®; To the computer, Android™ > iOSǂ devices | ■ |

ElcoMaster® PC software | ■ |

| 2-year instrument warranty2 | ■ |

| limits; 40 audible and visual pass/fail warnings can be defined | ■ |

Automatic sensor recognition | ■ |

|

Measurement mode

Measuring range 4

Accuracy5

Interface Echo (IE)

1.65-25.40mm

(0.065-1.000”)

±0.015mm (1.65-2.99mm)

±0.5% (3.00-25.40mm)

±0.0006” (0.065 0.117”)

±0.5% (0.118-1.000”)

Echo Echo (EE)

0.15 - 10.15mm

(0.006 - 0.400”)

±0.015mm (0.15-2.99mm)

±0.5% (3.00-10.15mm)

±0.0006” (0.006-0.117”)

±0.5% (0.118-0.400”)

Plastic Pattern (PLAS)

0.15 - 5.00mm

(0.006 - 0.197”)

±0.015mm (0.15-2.99mm)

±0.5% (3.00-5.00mm)

±0.0006” (0.006-0.117”)

±0.5% (0.118-0.197”)

| ■ |

Units of measurement | |

Millimeters and inches | ■ |

m/s, inch/µs | ■ |

Repeatability/stability indication | ■ |

Display mode | |

reading | ■ |

Selected Statistics, Scan Thickness Histogram, Trend Chart, Readings and Differences | ■ |

Selectable reading resolution | |

Lo; 0.1mm (0.01 Inch), 10m/s (0.001 in/μs) | ■ |

Hi; 0.01mm (0.001 Inch), 1m/s (0.0001 in/μs) | ■ |

statistics | |

Number of readings (n), average (average) (x), Standard Deviation (σ), Lowest Reading (Lo), Highest Reading (Hi), Coefficient of Variation (CV%) | ■ |

Low/High Limit , Reading Range , Nominal , | ■ |

Calibration options | |

1 point and 2 point | ■ |

material selection; 39 preset materials | ■ |

Factory; Reset to factory calibration | ■ |

Speed of sound (speed of sound) | ■ |

A known thickness value | ■ |

calibration characteristics; | |

calibration memory; 3 programmable memories with optional PIN code calibration lock | ■ |

Calibration warnings other than measurements | ■ |

Data Logging | |

100,000 readings in 1000 alphanumeric data sets | ■ |

Fixed data group capacity mode; With data set links | ■ |

Date and time stamping, review, purge, and delete data groups | ■ |

Data set recap chart | ■ |

Technical Specifications: | ||||

Part number | Description | certificate | ||

C307CDL | Elcometer 307 Ultrasonic Precision Thickness Gauge | • | ||

C307CDL-TXC | The Elcometer 307 Ultrasonic Precision Thickness Gauge features a 15MHz 1/4" helical right angle single element sensor | • | ||

Sensor probe type | Single crystal | |||

Measurement mode | Measuring range 4 | Accuracy5 | ||

Interface Echo (IE) | 1.65 - 25.40mm (0.065 - 1.00”) | ±0.015mm (1.65-2.99mm) ±0.5% (3.00-25.4mm) | ±0.0006” (0.065-0.117”) ±0.5% (0.118-1.000”) | |

Echo Echo (EE) | 0.15 - 10.15mm (0.006 - 0.400”) | ±0.015mm (0.15-2.99mm) ±0.5% (3.00-10.15mm) | ±0.0006” (0.006-0.117”) ±0.5% (0.118-0.400”) | |

Plastic Pattern (PLAS) | 0.15 - 5.00mm (0.006 - 0.197”) | ±0.015mm (0.15-2.99mm) ±0.5% (3.00-5.00mm) | ±0.0006” (0.006-0.117”) ±0.5% (0.118-0.197”) | |

resolution | 0.1mm (0.01") or 0.01mm (0.001") switchable | |||

Measurement rate | 4, 8 & 16Hz (4, 8 & 16 readings per second) | |||

Operating temperature | -10 to 50°C (14 to 122°F) | |||

Data output | USB & Bluetooth® | |||

power supply | 2 x AA batteries | |||

| Battery life6 |

Alkaline battery: about 15 hours | |||

Instrument weight | 210g (7.4oz) - Batteries included, sensors not included | |||

Instrument size | 145 x 73 x 37mm (5.7 x 2.87 x 1.46") - Sensors not included | |||

Packing list | Elcometer 307 Ultrasonic Precision Thickness Gauge , 15MHz Transducer (C307CDL-TXC Only) , Ultrasonic Couplant , Carry Bag , 3 x Screen Protector, Wrist Sling, 2x AA Batteries, Instruction Manual, Transport Case, Calibration Certificate & 2 Year Warranty Extension Card, ElcoMaster® Software CD & USB Cable | |||