SITA dynamic Surface Tensiometer with type 4 disposable PTFE capillary tubing

SITA Dynotester+ Surface TensioMeterSPEC

SITA Dynotester+ Surface TensioMeterDetails

SITA Dynotester+ Surface TensioMeterPacking list

- SKU

- NB041799

- Surface tension Measurement Range

- 10~100mN/m

- Bubble life range

- 15-20000ms

- test mode

- Single Mode

- Measurement of liquid temperature

- 0-100℃

- Dimensions

- 168*75*35mm

- Probe length

- 68mm

- Weight

- 230g

- Resolution

- 0.1 mN/m

- Reproducibility

- 0.5 mN/m

- Storage space

- Twenty-five.

- Battery life

- More than 10 hours

product description

The German SITA column surface tensIon Meter can measure the dynamic and static surface tension of liquids, monitor the quality of the bath liquid during the cleaning process, and establish a good foundation for R&D and cleaning processes to obtain high-quality results.

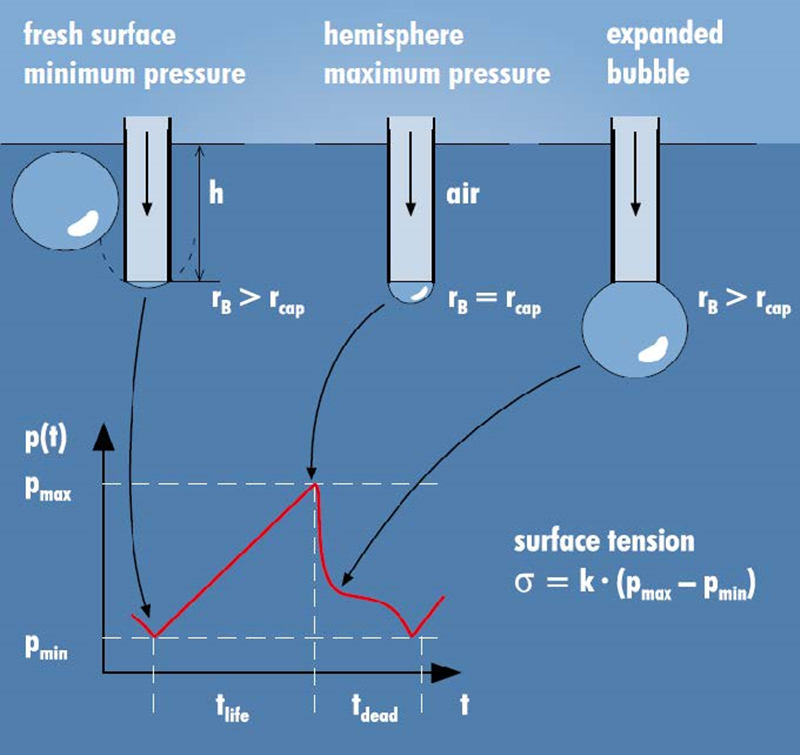

Principle

The bubble pressure method is used to measure the dynamic and static surface tension of liquids without the need to precisely control the capillary immersion depth. The measurement accuracy is high and the operation is flexible. Air is blown through the capillary tube into the liquid to be measured. The pressure inside the bubble continuously changes as the bubble radius changes. Therefore, surface tension can be calculated from the difference between the maximum and minimum pressure values. The instrument can be automatically calibrated using pure water.

Features

The test time only takes 30 seconds to obtain dynamic or static surface tension, making the test quick and easy

Accurate and automatic control of bubble life to achieve stable and high-precision dynamic testing

Preset test parameters and can directly store measurement data for easy operation. The test data is consistent with all SITA Surface Tensiometers.

use

During the cleaning process, monitor the surface tension (surfactant concentration) of the cleaning bath liquid to stabilize the cleaning quality.

In factories and laboratories, monitoring the surface tension of surfactant liquids for R&D and quality inspection

Test the quality of inkjet and ink

Quality control of incoming raw materials for surfactants and additives

It is portable and can achieve stability and high precision, and is suitable for use in many occasions such as laboratory research and development, quality inspection and production sites.

Dynotester+

Dynotester+