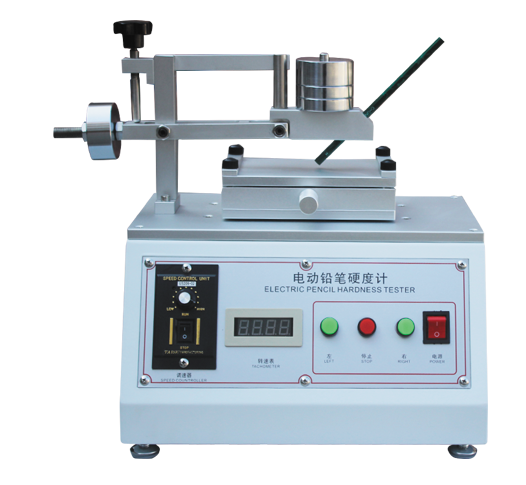

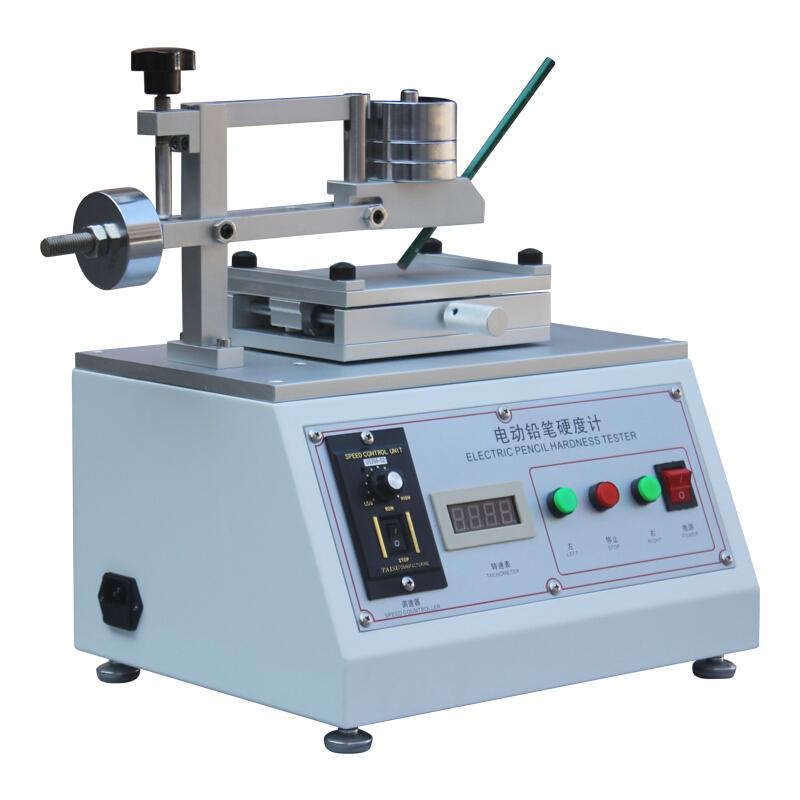

CHINA NBC-5608 Pencil Hardness Tester Pencil Hardness Tester

SEHuiNuo NBC-5608 Pencil Hardness TesterSPEC

HuiNuo NBC-5608 Pencil Hardness TesterDetails

HuiNuo NBC-5608 Pencil Hardness TesterPacking list

- SKU

- NB044534

- test angle

- 45°

- Nominal Mass

- 500g、250g、250g

- Test platform traverse speed

- 5Mm/sec, adjustable

- travel distance

- 40mm

- Platform size

- About 120 * 170mm, can fix the sample

- test fixture

- A set of fixed sample fixtures

- Power Supply

- AC220V、50HZ

- pencil

- Standard pencil 6B~ 6H 1 each, a total of 13 pcs

Instrument introduction

The electric pencil hardness testing machine is specially used to test the spray hardness of various finished products, such as: mobile phone casings, MP3/MP4 casings, laptop casings and other types of home appliance digital product casings. The machine is electric (semi-automatic) controlled. The machine moves through a stepper motor to realize forward and backward movements, with low noise and stability! The Test Travel is adjustable according to specific requirements!

Principle

This instrument is mainly composed of a pencil holder and a test bench. The pencil holder and the column form a four-link structure, which ensures that the weight of the weight acts vertically on the intersection of the pencil lead and the test bench, and makes the pencil and the test bench form a 45° clamp. angle and remain unchanged. The test bench can move horizontally and vertically. Use it to fix the paint sample and slide the sample in the scratch direction, and the pencil will draw the corresponding track on the test piece. Use different pencils to make different marks, based on which the hardness value of the coating film can be determined.

Test instruction

Use a hardness pencil to scratch the surface of the coating to test the surface hardness of the coating. The hardness pencil is fixed at an angle of 45° so that the tip of the pen is in contact with the surface of the coating, and an appropriate load is applied. At a certain speed (JIS standard 0.5mm/second) ) Move the test platform so that the surface of the coating layer moves through the center of the pen. The grade of the soft pencil that will not cause damage (scratches) to the coating layer can be regarded as the hardness of the coating layer.

standard test

JIS-C3003, D0202, (K5400), K5600-5-4, K5651, K6894, K6902, ASTM-D2197, D3363, ISO-15184, GB/T6739

- 1ISO 《Paints and varnishes — Determination of film hardness by pencil test》

- 2JB/T 3078-2015《Varnishes used for electrical insulation.Silicone impregnating varnishes》

- 3SJ 20910A-2018《General specification for powder spraying coating》

- 4WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 5JJF (石化)007-2018《Calibration Specification for Pencil Hardness Testers》

- 6SY/T 4106-2016《Specification of solvent - free polyurethane coatings for steel pipelines and tanks》

- 7 002-2017《Water based polyurethane coatings》

- 8GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 9GB/T 6739-2022《Paints and varnishes—Determination of film hardness by pencil test》

- 10HG/T 4758-2014《Water-based acrylic resin coatings》

NBC-5608

NBC-5608