TQC VF2110 double-channel Fineness gauge 0-15µm/1.5µm with calibrated certificate

SE-

CHINA QXD-15 double-channel Grindometer Zirconia Ceramic Material 0~15μm$ 459.00SE

CHINA QXD-15 double-channel Grindometer Zirconia Ceramic Material 0~15μm$ 459.00SE -

TRUIT TR 1202/015 double-channel Fineness ruler 0~15μm$ 187.00SE

TRUIT TR 1202/015 double-channel Fineness ruler 0~15μm$ 187.00SE -

TQC VF2104 single-channe grinding Fineness of Grinding Gauge 0~15μm with calibrated certificate$ 1044.00SE

TQC VF2104 single-channe grinding Fineness of Grinding Gauge 0~15μm with calibrated certificate$ 1044.00SE -

Pushen 0-15um double-channel Fineness gauge 0~15μm$ 214.00SE

Pushen 0-15um double-channel Fineness gauge 0~15μm$ 214.00SE -

PUSHEN /Pushen QXD-15um single-channe fineness grindometer 0-15μm$ 285.00SE

PUSHEN /Pushen QXD-15um single-channe fineness grindometer 0-15μm$ 285.00SE

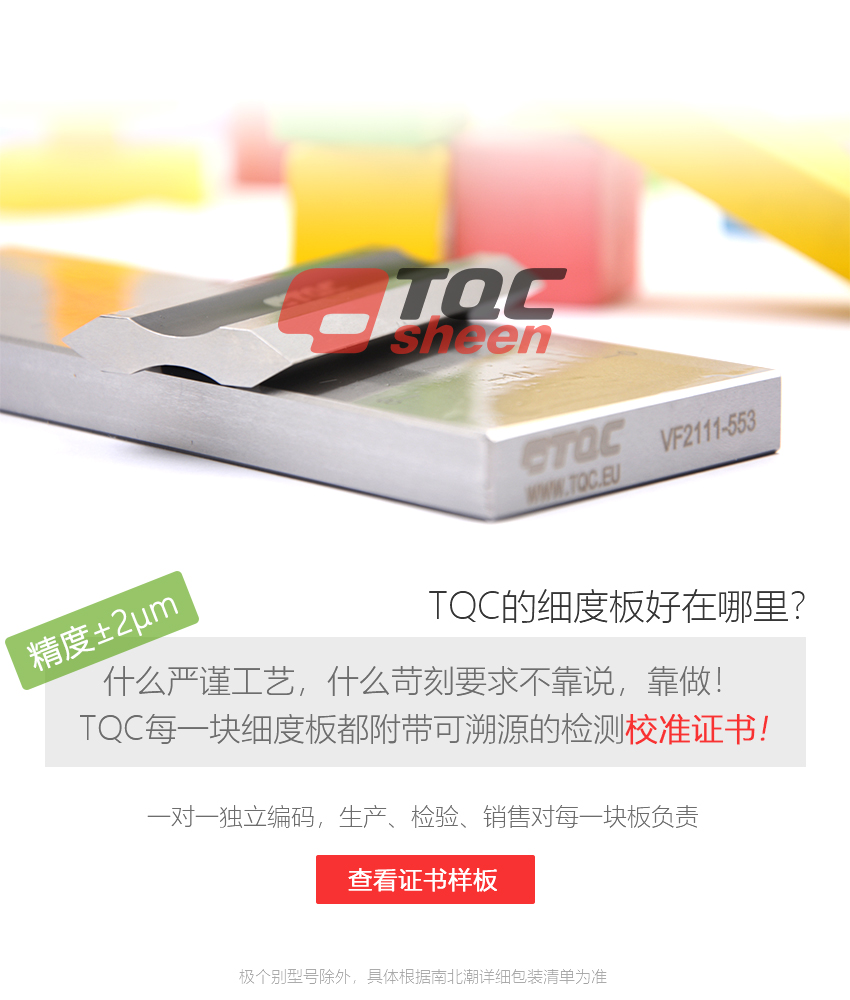

TQC sheen VF2110 Double-channel Fineness gaugeSPEC

TQC sheen VF2110 Double-channel Fineness gaugeDetails

TQC sheen VF2110 Double-channel Fineness gaugePacking list

- SKU

- NB000516

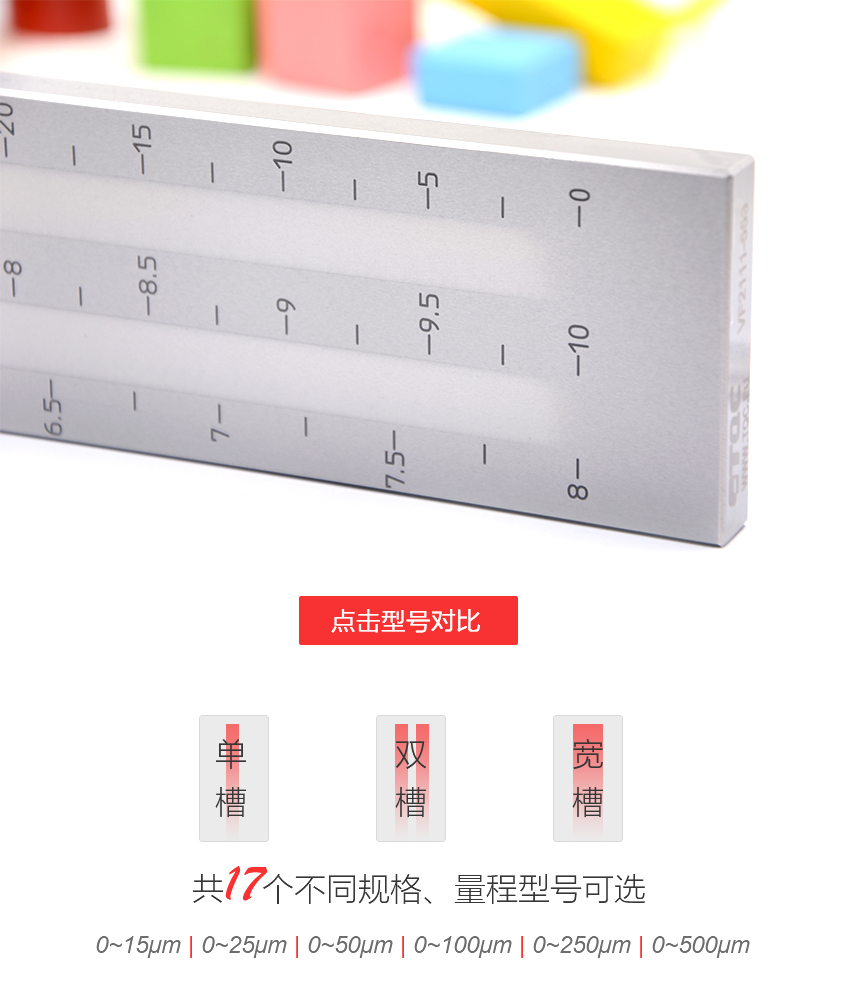

- Scraper type

- double-channel

- Number of grooves

- 2

- range

- 0~15μm

- Scale unit

- μm、Hegman、PCU

- Accuracy

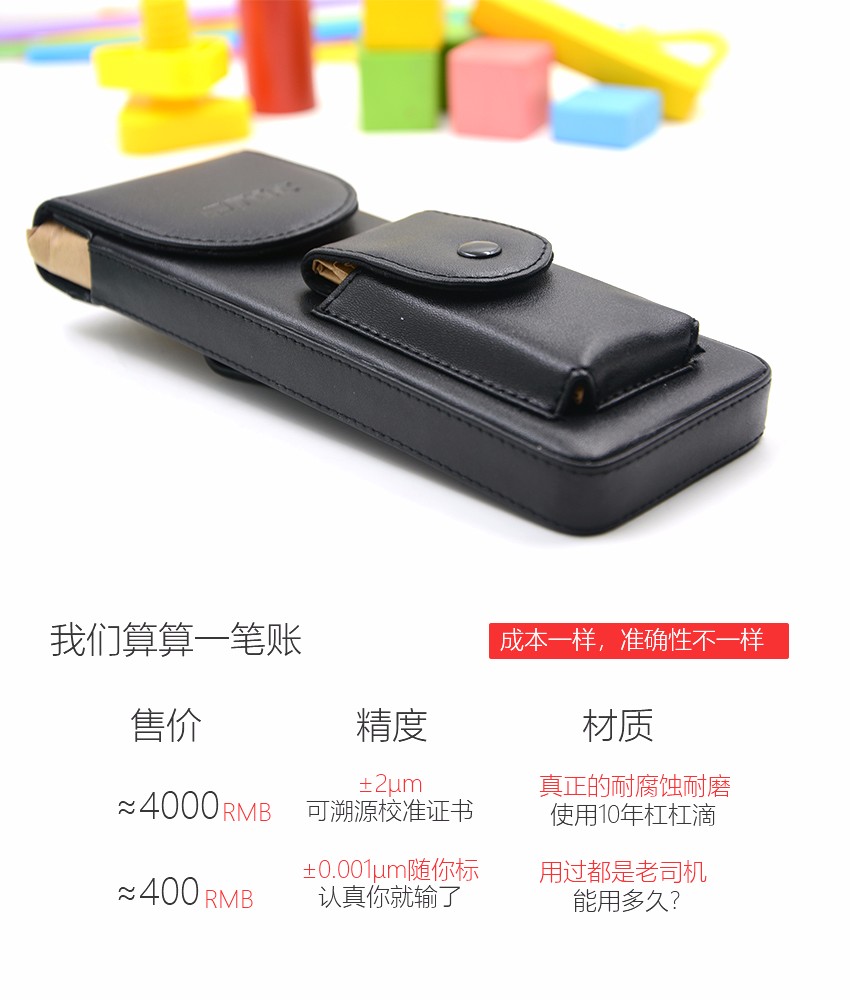

- ±2µm

- scraper material

- Swiss 1.2085 tool steel

- Scraper size

- 175*60*12mm

- Groove width

- 12mm

- Drawdown blade size

- 75*38*8mm

- Applicable standards

- ASTM D1210, ASTM D1316, DIN 53203, DIN EN ISO NF21524, FTMS 141 a, M.4411.1, NF T 30-046, ASTM D1084, ISO 1524, ГОСТ 6589

- Graduation

- 1.5μm

- Calibrated Certificate

- With Certificate

Overview of double channel Fineness gauge

The Dutch TQC VF2110 / VF 2111/ VF 2112/ VF 2113 double channel Fineness gauge is a scraper Fineness Meter with four different measuring ranges. The measured fineness ranges are 0~15μm , 0~25μm, 0~50μm, 0 ~100μm, the measured fineness accuracy is ±2 microns. The material of TQC double channel Fineness gauge is Swiss high-quality stainless steel, which has good wear resistance and corrosion resistance. VF2110/ VF 2111/ VF 2112/ VF 2113 double channel Fineness gauge is a double groove design.

Features

1. The TQC double-slot fineness plate scraper is made of hardened stainless steel. The surface is delicate, smooth and easy to maintain. It can be operated by hand during use.

2. The double-groove fineness gauge has double grooves and has 3 different parameters: micron, Hegemann, and North slope, which is a graded slope design.

3. In addition to measuring the fineness of paint, the TQC fineness plate scraper can also measure the fineness of many materials such as coatings, pigments, raw materials, plastics, printing inks, etc.

4. TQC fineness plates can also be used to test the fineness of products in chocolate, ceramics, paper, food and other industries, and there are more application areas.

Overview of fineness testing

During the fineness testing process of pigments, the pigments need to be ground into finer particles for dispersion in fluid equipment. The physical properties of the final dispersion are usually called "fineness", which not only depends on the actual size of the individual particles, but also depends on them. The extent to which it is dispersed. The pigment fineness can be quickly measured using the pigment fineness board.

Instructions

To summarize: Pour a little more of the sample to be measured into the deep end of the groove, and use the matching scraper to scrape the sample to be measured toward the shallower end of the groove at an appropriate angle and at a steady speed. After scraping, you can see many rough particles on the surface of the fineness plate, which are the corresponding test points.

Standard specific operations:

1. Wash the scraper and scraper with the specified solvent and wipe them dry with cotton gauze.

2. Mix the sample that meets the standard viscosity of the product thoroughly with an oil knife.

3. In the deepest part of the groove of the scraper Fineness Meter, drop a few drops of the sample so that it can fill the groove with a little excess.

4. Hold the spatula with the thumb, index and middle fingers of both hands. Place it horizontally on the upper end of the scraper Fineness Meter, make the scraper perpendicular to the surface of the scraper Fineness Meter, and pull the scraper from the deep part to the shallow part of the groove at a suitable speed, so that the paint sample fills the groove without leaving any excess on the plate. Excess paint.

5 Immediately (no more than 5 seconds) hold the Fineness Meter horizontally and tilt it so that the line of sight is at an angle of 15-30 degrees to the groove plane and observe the scale value where the particles in the groove are evenly exposed. The reading value is the fineness of the sample being measured. Spend.

Take you into the Dutch TQC

- 1SJ/T 10454-2020《Dielelectric paste for multilayer lay out of thick film hybrid integrated circuits》

- 2GB/T 21894-2008《A kind of photosensitive emulsion for plate making on fabric rotary screen printing》

- 3HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 4HG/T 5175-2017《Water-based decorative coating for glass and ceramic products》

- 5ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

- 6QB/T 5477-2020《Water-based printing ink for decorating paper》

- 7ASTM D1210-05-2022《Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage》

- 8JB/T 9385-2017《Scraper fineness gauges》

- 9ASTM D1316-2020《Standard Test Method for Fineness of Grind of Printing Inks By the NPIRI Grindometer》

- 10JJG 905-2010《Fineness of Grind Gage》

VF2110

VF2110