Film performance test -- wear resistance

Coating wear resistance is an important physical property of the coating to withstand mechanical wear in the use environment, and it is also one of the most widely used and most effective properties in the actual use process. Sum. The wear resistance of the coating is essentially the embodiment of the comprehensive effect of the hardness, adhesion and cohesion of the coating. The quality of the wear resistance of the coating is related to the substrate material, surface treatment, coating type and the process of the installation process. Conditions. Therefore, the measurement of the wear resistance of the coating is one of the important contents of the coating performance test, especially when the main purpose of the coating is wear resistance, it is more necessary to understand its wear resistance and then test it. .

The wear resistance test of the coating is generally to simulate the working conditions of wear, and conduct a comparative wear test to evaluate the wear resistance of the test layer. In practical applications, there are many types of wear, and the corresponding wear test methods There are many, the most commonly used are the following.

Abrasive Wear Test

There are generally two types of abrasive wear tests, one is the rubber wheel abrasive wear test, and the other is the pin-on-disk abrasive wear test.

Rubber wheel abrasive wear test

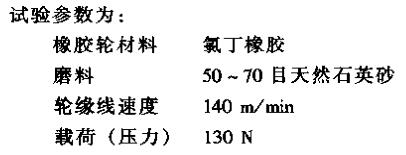

Abrasives with a certain particle size fall between the rotating grinding wheel and the square sample at a fixed speed through the feeding tube. The rim of the grinding wheel is rubber with a specified hardness. On the grinding wheel, the normal layer surface of the sample is in contact with the rubber wheel surface. The direction of rotation of the rubber wheel should be consistent with the flow direction of the material. During the rotation of the abrasive, the abrasive produces low stress on the sample. Abrasion. After a certain warehousing stroke, measure the weight loss of the sample, that is, the amount of coating reduction, and use this to evaluate the wear resistance of the coating. (Related instruments: wear testing machine)

A typical sample is a rectangular test piece of 50mmx75m, with a thickness of 10mm. Prepare the coating on its plane, and use a surface Grinder to grind the layer flat. The grinding direction should be parallel to the length of the sample, so that there is no crack on the surface of the coating. Deposition or iron sinking. Generally used

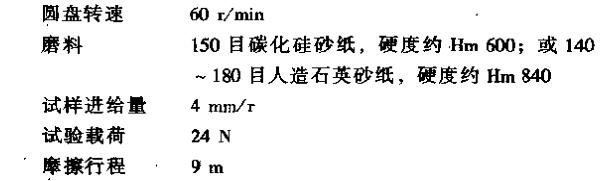

Pin-on-disk abrasive wear test

Put sandpaper or emery cloth on the disc as the abrasive of the testing machine. The sample is made into a pin type, and pressed on the return disc under a certain load pressure, and the coating of the sample is consistent with the disc sandpaper. Return Gold rotation. The sample moves linearly along the radial direction of the disc. After a certain friction stroke, the weight loss of the sample, that is, the wear amount of the coating, is measured to evaluate the wear resistance of the coating. The test equipment usually uses a pin Disk-type book material richness and loss testing machine. The sample adopts a cylindrical shape with a diameter of 4mm. Coatings are made on one plane end of the sample, and the book on the French layer is washed and cooled to make the surface free of any defects and attachments. The end face of the specimen should be perpendicular to its axis. The suggested test parameters are as follows:

Sand blowing test

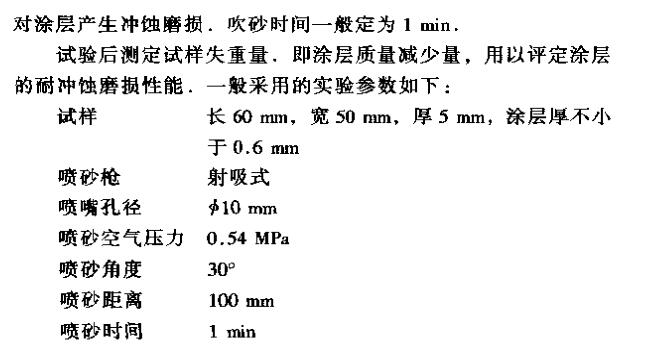

Erosion wear is the wear . These particles can be carried by gas or liquid and impact the surface of the part at a certain speed. The impact wear resistance of the part layer can be used Sand blowing test to evaluate.

During the test, put the sample in the sandblasting room, with the coating facing up, and fix it on the electromagnet disk . The surrounding area is protected by a rubber plate, and then the sandblasting gun is used to blow the sand with the sandblasting gun. Keep the sand angle and distance height unchanged, and maintain a certain sand blasting air pressure and sand supply rate. The abrasive is generally made of corundum sand. During the sand blowing process, the abrasive will cause erosion and damage to the coating. The sand blowing time is generally set at 1min. (related instrument: impact Tester)

Friction and wear test

Various frictional relative motions produce wear. There are many factors that affect wear, such as the material of friction parts, surface shape, friction motion form, working conditions, and sliding methods. It is difficult to test the wear resistance of the coating, and it is generally necessary to test the wear resistance of the coating by simulating the actual working conditions as much as possible.

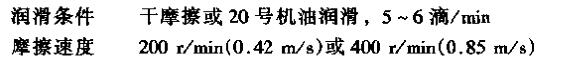

The test generally uses an abrasion testing machine. The sample is formed into a ring shape of 40mmx10 mm, and a ring groove with a width of 9 mm and a depth of 0.5 mm is pre-processed on the ring surface, and then various coatings are made on the ring cleaning, and the ring surface is placed on the mushroom bed. Grind to the size of the sample, clean up and test.

After the test, the weight loss of the sample is determined at temperature, that is, the reduction of the coating, and the resistance to decoating is evaluated based on this. Generally, the following test parameters can be used:

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Application of shakeout Tester in organic polymer film abrasion resistance testing

- 6Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 7Optical inspection device Anti-reflection film adhesion Measuring method

- 8Automatic scratch test to evaluate film strength, hardness, adhesion

- 9Comparison of film adhesion determination methods