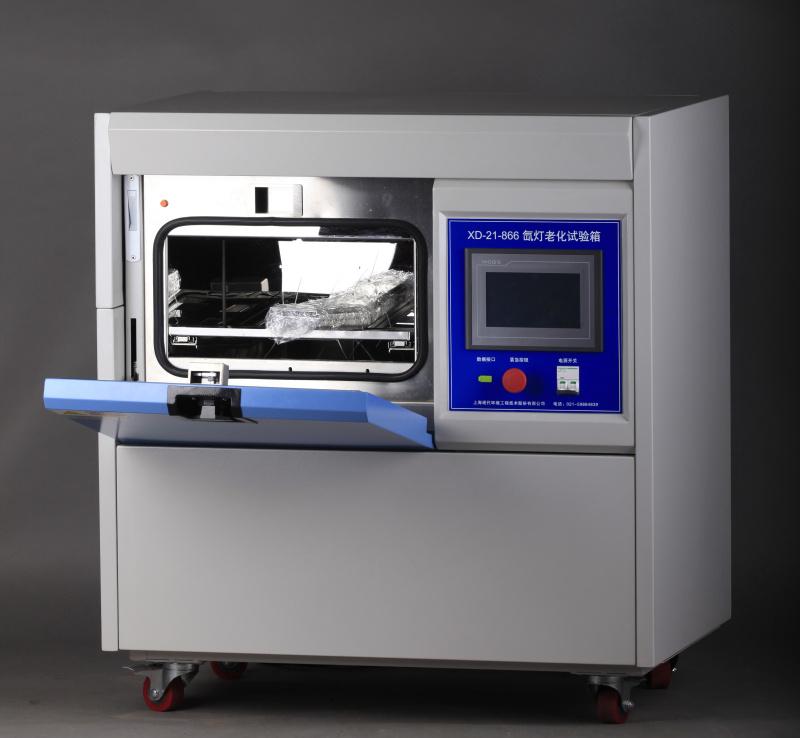

Application of xenon arc accelerated weathering Test Chamber in powder coatings industry

The xenon arc aging Test Chamber is a commonly used testing equipment that can be used to evaluate the weather resistance and durability of various materials under light, humidity, temperature and other environmental factors. In the field of powder coatings, xenon lamp aging Test Chambers can be used to evaluate performance indicators such as weather resistance, color stability, adhesion and corrosion resistance of powder coatings in outdoor environments.

Specifically, the application of xenon lamp aging Test Chamber in the field of powder coating mainly includes the following aspects:

Light resistance test: The xenon lamp aging Test Chamber can simulate the aging of powder coatings under different light intensities and wavelengths, and evaluate the light resistance and color stability of powder coatings. The test results can judge the light resistance of the sample by comparing the color difference value of the sample, which is helpful for the selection and development of powder coating materials with more light resistance.

Weather resistance test: The xenon lamp aging Test Chamber can simulate the aging of powder coatings under different environmental conditions, such as high temperature, high humidity, cold and hot cycles, etc., to evaluate the durability and corrosion resistance of powder coatings. The test results can judge the weather resistance performance of the samples by comparing the surface state, adhesion, cracks, yellowing, peeling and other indicators of the samples, which helps to select and develop more weather-resistant powder coating materials.

Anti-corrosion performance test: The xenon lamp aging Test Chamber can simulate the aging of powder coatings under different environmental conditions, such as salt spray, acid rain, etc., to evaluate the anti-corrosion performance of powder coatings. The test results can judge the anti-corrosion performance of the samples by comparing the corrosion, peeling, adhesion and other indicators of the samples, which is helpful for the selection and development of powder coating materials with more anti-corrosion properties.

Adhesion test: The xenon lamp aging Test Chamber can simulate the aging of powder coatings under different light and humidity conditions, and evaluate the adhesion of powder coatings. The test results can judge the adhesion performance of the sample by comparing the adhesion index of the sample, which helps to select and develop a powder with more adhesion performance

Final coating material.

Thermal stability test: The xenon lamp aging Test Chamber can simulate the aging of powder coatings at high temperatures and evaluate the thermal stability of powder coatings. The test results can be used to judge the heat resistance of the samples by comparing the heat stability indicators of the samples, which is helpful for the selection and development of powder coating materials with more heat resistance.

To sum up, the xenon arc aging Test Chamber is widely used in the field of powder coatings, which can help manufacturers evaluate the light resistance, weather resistance, anti-corrosion performance, adhesion and thermal stability of powder coatings, so as to optimize powder coatings The formulation and manufacturing process improve product quality and performance. In addition, the xenon lamp aging Test Chamber can also help manufacturers predict and control the performance of powder coatings in the actual use environment, thereby improving the market competitiveness and user satisfaction of products.

NBCHAO reminds you: the test results of the xenon lamp aging Test Chamber can only provide relatively quantitative information, but cannot completely replace the experimental data in the actual outdoor environment. Therefore, when designing and manufacturing powder coating products, it is necessary to comprehensively consider the test results of the xenon arc aging Test Chamber, the laboratory test results and the data in the actual use environment to ensure the quality and performance of the product. In addition, when performing the xenon lamp aging test, it is also necessary to strictly control the test conditions, such as light intensity, temperature, humidity, etc., to ensure the accuracy and repeatability of the test results.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Basic Principle, Functional Characteristics and Application of xenon arc aging Test Chamber

- 4Working principle and application of UV coating Cupping testing device

- 5Introduction of working principle and application scope of water-cooled xenon arc weathering Test Chamber

- 6Principle and Application Analysis of Film Adhesion Tester

- 7Optical inspection device Anti-reflection film adhesion Measuring method

- 8Automatic scratch test to evaluate film strength, hardness, adhesion

- 9Comparison of film adhesion determination methods