Detailed introduction to film adhesion and comparison of different test methods

Film adhesion is a measure of the bonding force between a coating and a substrate and is used to evaluate the adhesion performance of coatings. Here is a detailed introduction to film adhesion and a comparison of different test methods:

Definition and influencing factors of film adhesion

Film adhesion refers to the degree of bonding between the coating and the substrate, which is affected by physical and chemical factors. Coating wettability and substrate surface roughness also affect adhesion. The quality of adhesion directly affects the durability and protective performance of the coating.

Film adhesion testing method

Film adhesion can be determined by a variety of test methods, including Circle-drawing method, cross-cut method and pull method.

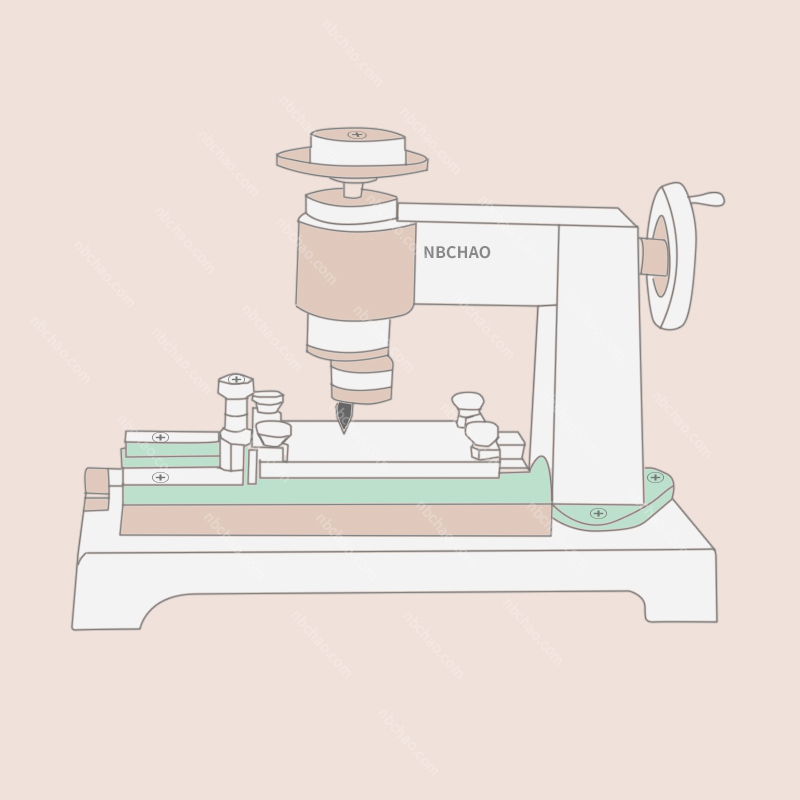

Circle-drawing method: Use the Circle-drawing adhesion Tester to draw a circular roller line on the coating, and evaluate the adhesion grade according to the integrity of the film within the scratch range. Simple operation, suitable for the determination of single coating adhesion.

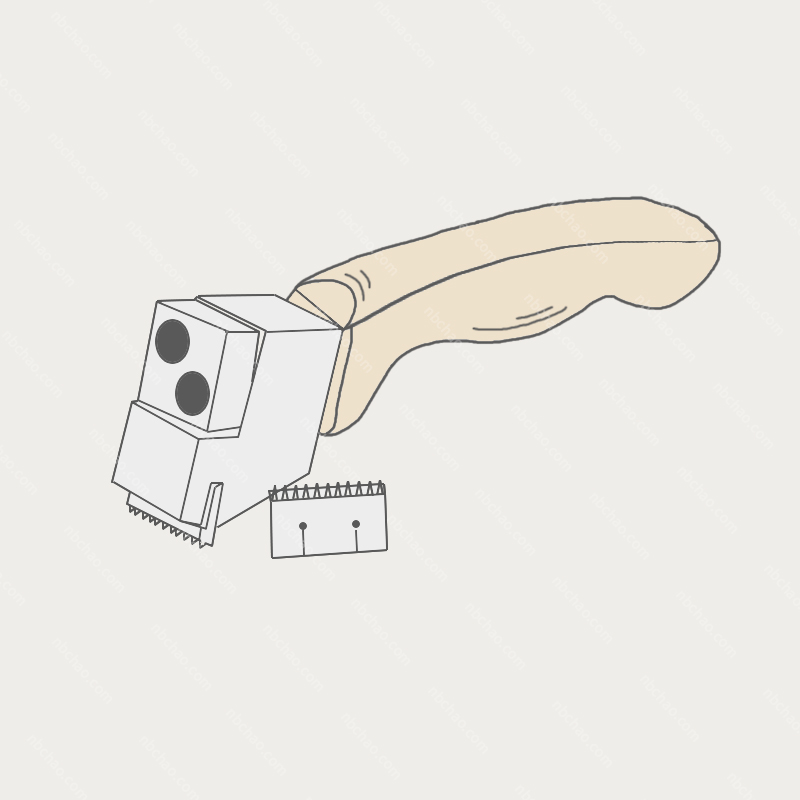

Cross-cut method: Using a high-alloy rigid cross-cut knife, the coating is cut into a crossed lattice. Evaluate the resistance of the coating to separation from the substrate, which is suitable for the determination of thicker coatings.

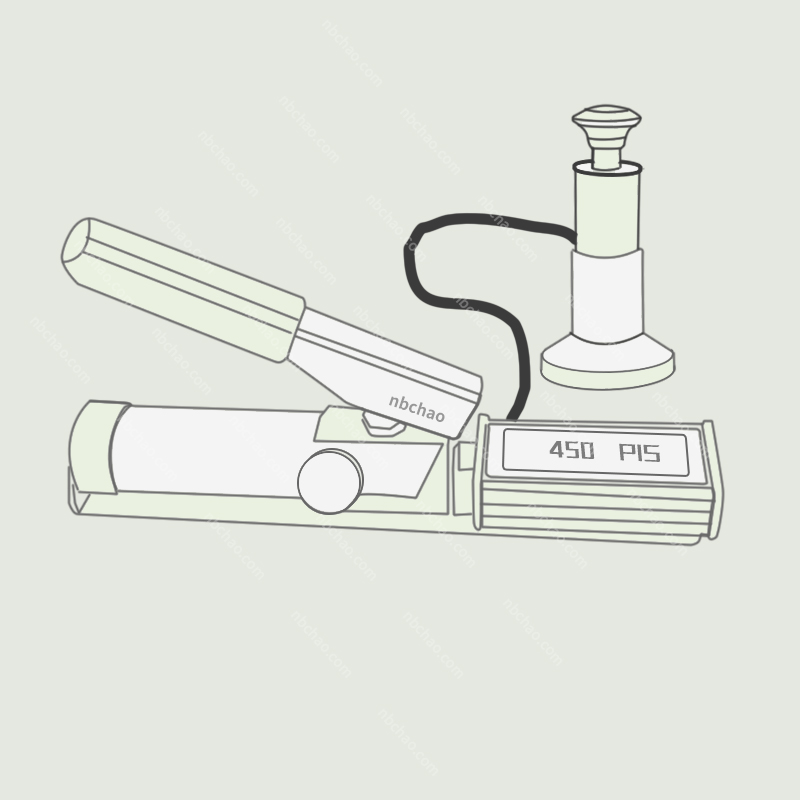

Pull method: At a specified speed, apply a vertical uniform tension to measure the force required for adhesion failure between coatings or between coatings and substrates. Suitable for the determination of thicker coatings.

Advantages and disadvantages of the three major adhesion testing methods

Circle-drawing method and cross-cut method are indirect measurement methods, the results obtained not only reflect the adhesion, but also include the deformation and damage resistance of the coating, but the operation is simple and widely used.

The pull-off method is a direct measurement method, which can numerically represent the adhesion of the coating. It is a method to inspect the compatibility of the coating and comprehensively evaluate the overall adhesion effect of the coating. However, the operation process is complicated, and the test can only be carried out after the Adhesive is completely cured.

Applicable standards for adhesion testing

Commonly used adhesion testing standards in CHINA include:

GB/T 5210 "Determination of coating adhesion - Pull-open method"

GB/T 9286 "Paints and varnishes paint film cross-cut test cross-cut method"

GB/T 1720 "Determination of paint film adhesion, circling method"

How to measure film adhesion

Paint film adhesion testing can use different methods, such as Circle-drawing method, cross-cut method and pull method. These methods choose the appropriate test method according to the thickness of the coating, the application environment and other factors.

Circle-drawing method: Use Circle-drawing adhesion Tester to scratch the paint film on the sample plate and observe the position of film peeling to determine the adhesion grade.

Cross-cut method: use a high-alloy diamond cross-cut knife to cut the grid of the coating transaction fork, evaluate the resistance of the coating to separate from the substrate, and apply to thicker coatings.

Pull method: At a specified speed, apply a uniform tensile force to determine the force required for coating adhesion failure. Suitable for thicker coatings, it can also be used for adhesion determination between coatings.

In short, film adhesion testing is an important part of evaluating coating performance, and different test methods are suitable for different types of coatings and application scenarios. Choosing an appropriate test method can accurately evaluate the adhesion performance of coatings, thereby ensuring the mass and service life of coatings.

-

RUNJIE RJ-M Adhesion Tester 14mm$ 1237.00

-

-

-

-

-

-

-

-

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof