Film Cupping Test: an important indicator of coating mass and performance

In modern industrial production, coatings are one of the important means to protect the surface of materials, enhance Appearance and improve durability. However, the mass and performance of coatings are often affected by various factors such as adhesion, hardness and abrasion resistance. In order to accurately evaluate the performance of coatings, paint film cupping test has become an indispensable experimental method.

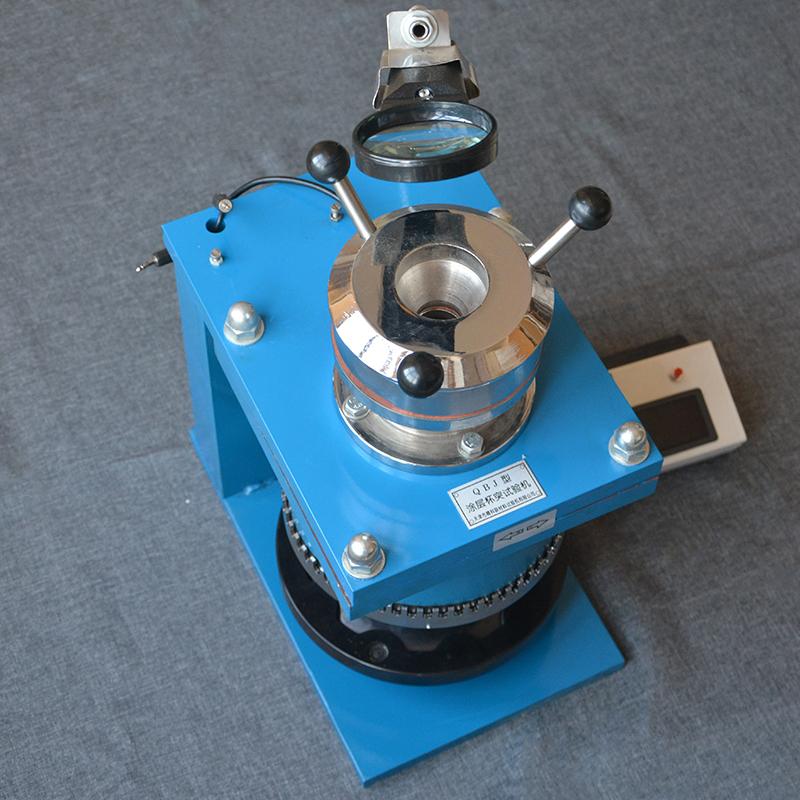

Introduction to paint film cupping test

Paint film cupping test is an experimental method to evaluate coating adhesion, hardness and durability by applying pressure. This test measures the performance change of coatings under pressure by applying standardized pressure on the surface of the coating to make it sinkage or protrusion. Paint film cupping test is widely used in Coatings, paint films, coating materials and other fields to study the mass, hardness, abrasion resistance, adhesion and other characteristics of coatings.

Testing principles and methods

The basic principle of the paint film cupping test is to insert a round or conical cup-shaped tool (usually metal) into the coating surface under standard test conditions, apply a certain pressure, and observe the performance of the coating. During the test, the pressure gradually increases. When the coating appears sinkage, cracking or protrusion, record the required pressure value, which is the paint film cupping value, also known as protrusion hardness or sinkage hardness.

The test method varies according to the type of coating and the shape of the cup. Common cup shapes include spherical, conical, etc. These shapes can simulate different types of stress. In addition, factors such as the thickness of the coating and the nature of the substrate need to be considered during the test to obtain more accurate test results.

Significance of test results

The results of the film cupping test provide important information for the performance of the coating. First, the film cupping value can be used to evaluate the hardness of the coating. Hardness is a key indicator of coating abrasion resistance and scratch resistance, which can reflect the resistance of the coating. For different types of coating materials, the hardness value will also vary.

Secondly, the film cupping value can also be used to evaluate the adhesion of the coating. Adhesion is the bonding strength between the coating and the substrate, which directly affects the durability and service life of the coating. Through the film cupping test, it is possible to evaluate whether the coating is easy to peeling and disbonding under the action of external forces.

In addition, the film cupping test can also be used to study the performance changes of coatings under different environment conditions. For example, in harsh environments such as high temperature, humidity or chemical corrosion, the performance of coatings may change, and the film cupping test can simulate these environments and provide a reference for the practical application of coatings.

Application and Significance

Paint film cupping test has a wide range of application values in many fields. In the Coating industry, it can be used to evaluate the performance differences of different formulations of Coatings and optimize the formulation of Coatings; in the automotive manufacturing industry, it can be used to inspect the mass and durability of automotive Appearance coatings; in the aerospace field, it can be used to test the performance of aircraft external coatings at high altitudes.

In addition, the film cupping test also has a wide range of applications in scientific research, material development and other fields. By comparing and analyzing the film cupping test results of different coating materials, researchers can better understand the performance differences of materials, so as to guide the development and application of New materials.

Conclusion

As an important coating performance evaluation method, paint film cupping test provides reliable data support for all walks of life. By measuring coating hardness, adhesion and durability, paint film cupping test can help people better understand the performance characteristics of coatings, guide the optimization of Coating formulations and the development of New materials. In the continuous development of science and technology, paint film cupping test will continue to play an important role in the field of coatings research, contributing to the performance improvement and application innovation of various coatings

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Application of shakeout Tester in organic polymer film abrasion resistance testing

- 6Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 7Optical inspection device Anti-reflection film adhesion Measuring method

- 8Automatic scratch test to evaluate film strength, hardness, adhesion

- 9Comparison of film adhesion determination methods