Anticorrosive coatings adhesion detection method

In the field of painting of Anticorrosive coatings, film adhesion is a crucial performance indicator. Film adhesion refers to the degree of adhesion between the coating and the substrate, which is directly related to the stability, durability and protective effect of the coating. Therefore, it is particularly important to accurately evaluate film adhesion and choose an appropriate detection method. This article will introduce the significance of film adhesion, common detection methods and their importance in practical applications.

Meaning of film adhesion

Film adhesion is an indispensable performance indicator in the process of Coating painting, and its quality directly determines the lasting performance of the film. Excellent adhesion can ensure that the coating is not easy to disbonding or peeling in different environments, thereby effectively protecting the substrate from corrosion. Not only that, film adhesion can also reflect the mass of the Coating itself, such as the choice of Resin and the rationality of the coating process. Therefore, by accurately detecting film adhesion, the mass of the Coating and the Reliability of the coating process can be evaluated, providing a strong guarantee for the mass of the painting.

Common film adhesion detection methods

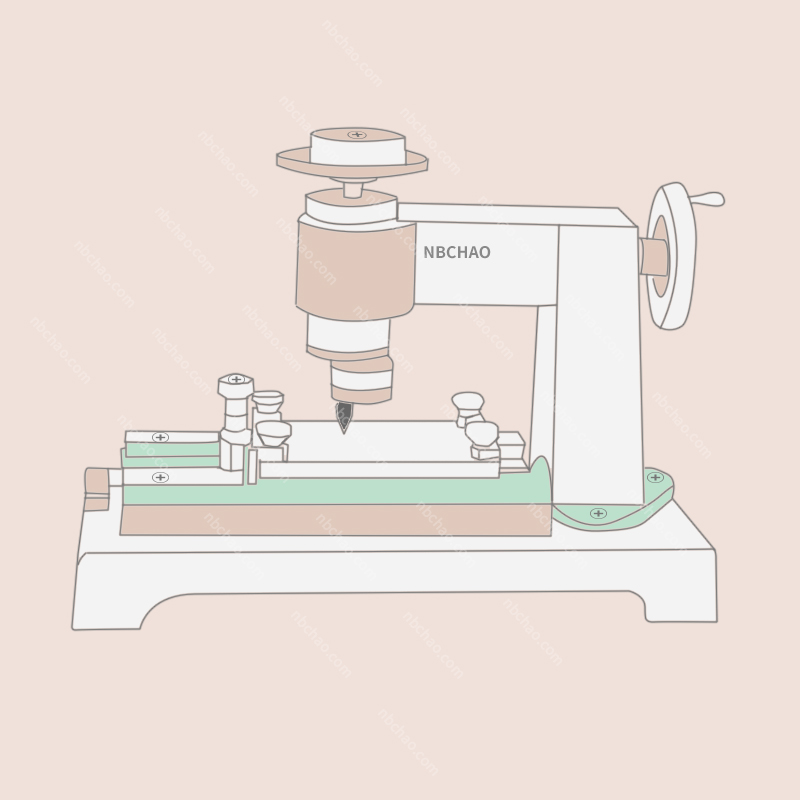

Circle-drawing method

This is a commonly used on-site rapid detection method. Circles are drawn on the film surface and rated according to the integrity of the scratch to judge film adhesion. Although easy to operate, the results may not be accurate due to operator skills and the sharpness of the scratch tool.

Cross-cut method

Use a cutter to draw a certain distance of cuts on the film, and then grade the film according to the condition of the cut film. This method can be applied in the laboratory and in the field, and the evaluation results are relatively accurate, and it is suitable for different film thicknesses and substrates.

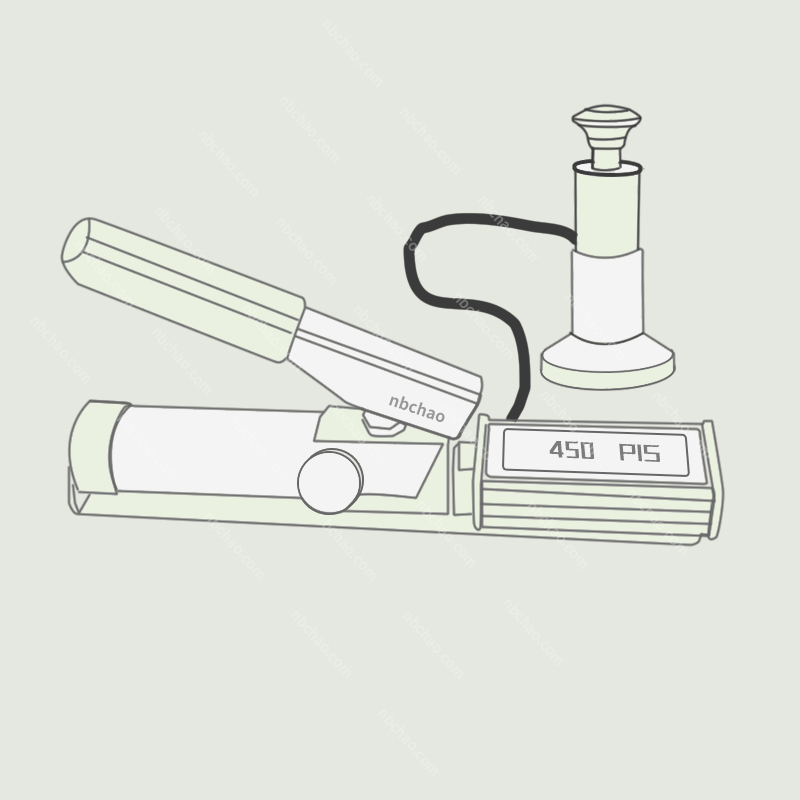

Pull method

Determine the force required for coating adhesion to break by applying a vertical pull force at a certain rate. This method not only evaluates the adhesion of the film to the substrate, but also detects the adhesion between coatings. Especially suitable for thick coatings.

Importance of film adhesion detection method

Film adhesion detection method has important value in practical applications. First of all, it can help Manufacturers and construction units to ensure Coating mass. By performing adhesion detection after neutralizing painting during the painting process, poor Coating or coating process problems can be detected in time to ensure the stability and protective effect of the coating. In addition, film adhesion detection method is also of great significance in the field of maintenance and repair. For example, when coating a new Coating on an existing coating, it is necessary to ensure that there is sufficient adhesion between the old and new coatings to avoid coating disbonding. Through adhesion detection, the durability and life of the coating can be evaluated to provide a basis for coating maintenance.

NBchao conclusion: The film adhesion detection method is one of the key links in evaluating the performance of Anticorrosive coatings. Selecting an appropriate detection method, combined with practical application requirements, can comprehensively evaluate the adhesion of coatings, ensure the painting mass, and improve the protective performance and service life of coatings.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof