Adhesion test standards and methods for coating films

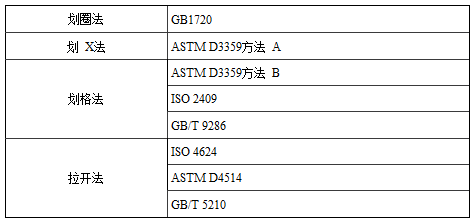

The detection methods of coating adhesion mainly include the circle method, the cross-cut method, the X-cross method and the pull-off method. different detection methods,

The corresponding standards are shown in Table 1. Among them, the circle-drawing method is not suitable for the inspection of the adhesion of the coating film on the coating site, but is only suitable for the detection of the coating film performance in the laboratory.

Table 1 Testing methods and standards for coating adhesion

1. Circle method

The adhesion Tester used in the circle method is evaluated according to the integrity of the paint film within the scratch range, expressed in grades. It is fixed on the Tester according to the prepared tin plate. In order to ensure that the paint film is cut through, add weights as appropriate, and shake the handle clockwise at 80-100r/min evenly to scratch with a circular rolling line. The standard circle 7.5cm long, take out the model, and grade. The following points should be paid attention to in the experiment:

(a) The needle of the Tester needs to be kept sharp, otherwise the difference between grade 1 and grade 2 cannot be distinguished. You should feel whether it is sharp by touching it with your fingers before measuring, or change it as appropriate after measuring several test panels.

(b) Try scratching a few times first, the scratches should just cut through the paint film, if the bottom plate is not exposed, add weight as appropriate; but do not add too much, so as not to increase resistance and wear the needle.

(c) When grading, you can start with level 7 (the innermost layer), or you can rate with level 1 (the outermost circle), and check the integrity of the paint film in each part in sequence. The part is considered intact, otherwise it is considered damaged. For example, if the paint film of part 1 is intact and the adhesion is very good, it is rated as grade 1; if the paint film of part 1 is damaged and the paint film of part 2 is intact, the adhesion is rated as grade 2. By analogy, grade 7 has the worst adhesion. Generally, it is required that the adhesion of a relatively good primer should reach level 1, and the adhesion of the topcoat can be around level 2.

2. Cross-cut method

The cross-hatch test standards mainly include ASTM D3359 Method B and ISO 2409. The test methods and descriptions of the two are basically the same, but the order of the adhesion level is just reversed. ASTM D3359 is 5B~0B for good to bad, while ISO 2409 is 0~5 for good to bad. my country's national standard GB/T9286-1998 is equivalent to ISO2409:1992.

Here mainly introduces the test method of ISO 2409.

The knives used in the ISO 2409 cross-hatch test are both multi-edged and single-edged, single-edged knives are recommended as multi-edged knives do not cut the paint film smoothly for >120μm dry film thickness or harder coatings . In order to avoid human error, an electric cross-cut adhesion Tester can be used, and the tool pressure can be adjusted in advance. Some instrument companies, such as the Model 430 produced by the German Erichzen Instrument Company, can perform tests of various specifications such as single-row, multi-row, star and wedge. With single-edged tools, instruments with different pitches are also required. Transparent pressure-sensitive tape and a 2x or 3x magnifying glass are also indispensable experimental aids.

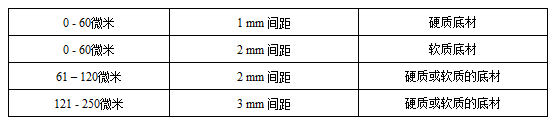

Different paint films determine different grid spacing, and the hardness of the substrate also affects it, see Table 2.

Table 2 The grid spacing corresponding to different paint film thicknesses and substrates

0 - 60 microns 1 mm spacing on rigid substrates 0 - 60 microns 2 mm spacing on soft substrates 61 - 120 microns 2 mm spacing on hard or soft substrates 121 - 250 microns on 3 mm spacing rigid or flexible substrates Substrate

The cross-hatch test procedure is as follows:

(1) Measure the thickness of the paint film to determine the appropriate cutting spacing

(2) Cut the paint film at a constant speed with a stable pressure and an appropriate spacing to ensure that each knife cuts the surface of the substrate

(3) Repeat the above operation, and cut the paint film in parallel and equal numbers again at an angle of 90° to form a grid

(4) Sweep the surface with a soft brush. Unroll the tape in a steady state and cut off a 75mm length

(5) Put the middle of the tape on the grid, parallel to the scribed line, leave at least 20mm of length outside the grid to hold it with your hands, and smooth the tape with your fingers

(6) Hold one end of the tape and tear off the tape at an angle close to 60° within 0.5~1.0s. Keep the tape as a reference to check the condition of the cut

It is stipulated in ISO 12944 that the adhesion must reach level 1 to be qualified; in GB/T 9286-1998, the first 3 levels are satisfactory, and the first 3 levels are also used as the evaluation requirements for passing/failing assessment .

3. Draw X method

ASTM D3359 formulated by the American Society for Testing and Materials applies to dry film thicknesses higher than 125 microns, and there is no limit to the maximum paint film thickness, while the corresponding cross-hatch method is usually applicable to dry film thicknesses below 250 microns.

The tools required for the test are relatively simple, sharp blades, such as utility knives and scalpels; 25mm (1in.) translucent pressure-sensitive tape; an eraser at the end of a pencil, and a lighting source, such as a flashlight.

The test procedure is as follows:

(1) The surface of the coating should be clean and dry, high temperature and high humidity will affect the adhesion of the tape

(2) The soaked sample should be cleaned with a solvent, but the coating should not be damaged, and then allowed to dry

(3) Use a knife to stably cut the paint film to the substrate along a straight line, the included angle is 30-45°, the length of the line is 40mm (1.5 in.), and the intersection point is in the middle of the line length

(4) Use lighting to check the reflection of the steel substrate, and make sure that there are no scratches on the substrate; if not, re-cut at another position

(5) Remove the two circles above the pressure-sensitive tape, then pull the tape at a steady rate to cut off a 75mm (3in.) long tape

(6) Put the middle part of the tape on the intersection point of the cut, smooth it with your fingers, and then smooth the tape with an eraser. The color of the transparent tape can help us see the degree of density in contact with the paint film.

(7) Within 90±30s, tear off the tape from the surface of the paint film at 180°, and observe the state after the coating is pulled apart. Five states are defined in the standard for reference, among which 5A-3A is the acceptable state of adhesion.

5A: No flaking or peeling

4A: There are traces of peeling or peeling along the knife mark

3A: There are notches on both sides of the knife mark, which fall off up to 1.6mm

2A: There are notches on both sides of the knife mark, which fall off up to 3.2mm

1A: Most of the area X under the tape has come off

0A: The shed area exceeds the X area

4. pull apart

The pull-off method is a good test method to evaluate the adhesion. The aluminum alloy cylinder is glued to the surface of the coating with an adhesive. After the adhesive is completely cured, the adhesion is tested with a pull-off test instrument.

Applied standards are GB5210 (equivalent to ISO 4624), and ASTM D4514.

There are two types of pull-off test instruments: mechanical and hydraulic/pneumatic. Typical test instruments are Elcometer106 (mechanical) and Elcometer108 (hydraulic). The Elcometer106 manual mechanical pull-off method Tester, because it affects the accuracy of the test results due to the instability of manual operation, so the mechanical pull-off method Tester is no longer used in the marine anti-corrosion engineering standard NORSOK M501.

拉开法附着力测试时,使用的胶黏剂有两种,环氧树脂胶黏剂和快干型氰基丙烯酸酯胶黏剂。环氧胶黏剂在室温下要24 小时后才能进行测试,而快干型氰基丙烯酸酯胶黏剂室温下15 分钟后即能达到测试强度,建议在2 小时后进行测试。

透明胶带的作用主要是用来固定刚黏上的铝合金圆柱,以免胶黏剂没有固化到一定牢度而使圆柱偏离原来的黏着位置。

切割刀具用来切割铝合金圆柱周边的涂层与胶黏剂,直至底材,这样可以避免周边涂层影响附着力的准确性。如果干膜厚度低于150μm 时,可以不进行切割处理。

为了便利起见,ISO4624 中规定了一系列符号来描述其状态:

A = 底材的内聚力破坏

A/B = 底材与第1 道漆间的附着力破坏

B = 第1 道漆的内聚力破坏

B/C = 第1 道涂层与第2 道涂层间的附着力破坏

n = 多道涂层系统中第n 道涂层的内聚力破坏

n/m = 多道涂层系统中第n 道涂层与第m 道涂层系统的附着力破坏

-/Y = 最后1 道涂层与胶黏剂间的附着力破坏

Y = 胶黏剂的内聚力破坏

Y/Z = 胶黏剂与测试圆柱间的附着力破坏

附着力的强度以 N/mm2(MPa)来表示,在常用的Elcometer 108 上面显示的是MPa。比如一个涂层系统的拉开应力为20MPa,在圆柱上面和第一道涂层上有30%的涂层内聚力破坏,第一道涂层与第二道涂层的附着力破坏达到70%的圆柱面积,则可以表述为:

20MPa,30%B,70%B/C

在NORSOK M501 中,对有机涂层的附着力测试规定要求需要使用自动拉开式仪器,而不能使用手动机械式。防腐蚀涂料体系通常至少要求达到5.0MPa。对于防火涂料,水泥型的要求达到2.0MPa,对于环氧类产品要求为3.0MPa认可为合格。

ISO 12944-6 中对于涂层系统(干膜厚度大于250微米时)的附着力要求为按照ISO 4624拉开法附着力测试,至少要达到5MPa。

For the maintenance of the old coating, the reference value must reach at least 2MPa, and it can be considered that the original coating has a certain adhesion and can be retained. Otherwise the old coating shall be removed.

The adhesion between anti-corrosion coatings and concrete surfaces of newly built structures is generally not less than 1.5MPa. GB5210-85 is formulated with reference to the international standard ISO4624-1978, and the adhesion of coatings is in kg/cm2.

The rules for the form of damage are as follows:

Adhesion damage: the damage of the interface between the coating and the substrate and the composite coating, represented by A;

Cohesive failure: the coating itself is destroyed, represented by B;

If the adhesive itself is destroyed or the topcoat part of the tested coating is torn, it indicates that the adhesion between the coating and the substrate or the interfacial adhesion between the coatings has no value, expressed in C.

Bonding failure: The adhesive is detached from the uncoated test column, or completely detached from the topcoat of the coating to be tested, represented by D; when the failure mode is A, B or C, the measurement result is consistent with the adhesion required by the test. If there are two or more damage forms, the percentage of the damage area should be indicated, and greater than 70% is effective. When D appears, the selection, process and quality of the adhesive should be inspected or replaced. When C appears, it indicates that the strength of the adhesive cannot meet the requirements, and materials with higher strength can be replaced.

The test results are expressed in the form of adhesion and destruction, such as 75kg/cm2 A

The pull-off method is a destructive coating inspection method. In order not to damage the coating, it can be used in the adhesion pull-off test.

The basic requirement is to specify a certain pull-off strength, and the test can be stopped as long as this strength is reached, so as to avoid

A new point of weakness is created on the coating, and if the coating is torn off, it is a non-compliance. This is more convenient for on-site coating testing

Reasonably favorable.

- 1Principle and Application Analysis of Film Adhesion Tester

- 2GB/T 1720 Determination of paint film adhesion: Circle method

- 3Advantages and disadvantages of three methods of film adhesion

- 4Talking about ASTM D4541 film adhesion drawing test

- 5What are the tips to prevent sand inclusion and dry spray of paint film?

- 6Analysis of surface defects of blisters/blisters-anti-corrosion coatings

- 7Two defects of paint film adhesion - saponification and undercutting

- 8Operation steps of QFZ circle method paint film adhesion Tester

- 9Resin varnish _ thick film coating _ performance testing scheme [with instrument list]