Testing the impact resistance of plastic films by free falling dart method

The free-falling dart method is to measure the energy when 50% of the plastic film and sheet samples are damaged under the impact of a free-falling dart at a given height, and the impact resistance of the plastic film or sheet with a thickness less than 1mm is expressed by the impact damage mass.

(1) Test principle

When the falling dart falls from a certain height of the free falling dart impact testing machine, it impacts the sample with a certain kinetic energy. The greater the mass of the falling dart, the greater the kinetic energy and the greater the impact energy. The work done by the falling dart on the sample:

W=mgh-1/2mV²

In the formula, W——the work done by Luoshu on the sample;

m - the quality of the falling dart;

h - the drop height of the dart;

V—the impact velocity of the falling dart on the sample.

When the sample is damaged, V=0, then there is W=mgh, that is, the work done by the falling dart on the sample is proportional to its mass. Therefore, the quality of the falling dart can be used to measure the impact resistance of the plastic film.

(2) Test equipment

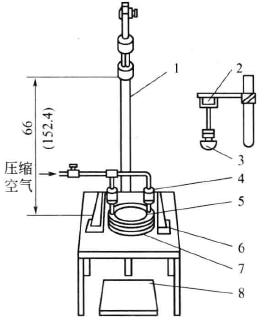

Figure 3-30 Principle of falling ball impact testing machine

1-column; 2-electromagnet; 3-impact head; 4-pressing cylinder; 5-movable platen; 6-sample; 7-fixed platen; 8 rubber pad

The test equipment used in the free falling dart method is a falling ball impact testing machine, as shown in Figure 3-30, which consists of a falling dart, a sample fixture, an electromagnet, a positioning device, a buffer and a protective device, and a locking ring. The falling dart is made of smooth, polished aluminum, phenolic plastic or other low-density material of similar hardness. It needs to have a hemispherical head on which a diameter of (6.5 ± 0.1) mm and a length of at least 115 mm is mounted. A round handle for loading and unloading weights. The round handle is made of non-magnetic material and has a steel pin at the end, which is attracted when the electromagnet is energized. The quality deviation of each falling dart is ± 0.5%. The surface of the dart head should be free from nicks, scratches or other defects. The electromagnet needs to be able to attract or release a falling dart with a mass of 2000g.

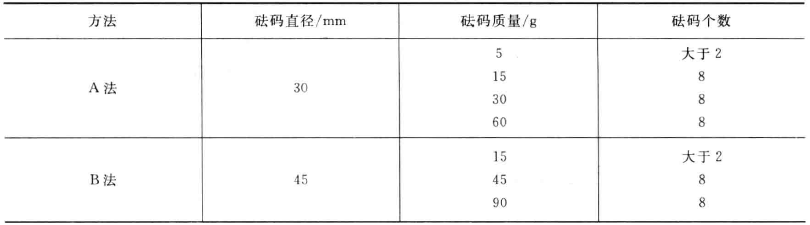

The weight is a cylinder made of stainless steel or brass with a central hole of (6.5 ± 0.1) mm in diameter. Each weight needs to be controlled within ± 0.5% of the specified mass. During the test, weights can be selected as required, as shown in Table 3-8.

Table 3-8 Weight series

For example, the XJB-30J dart impact testing machine produced by Chengde Jiande Testing Instrument Co., Ltd. is suitable for impact testing plastic films and sheets, and its main technical parameters are as follows.

①Operating temperature: 10~35℃.

②Mass of falling dart: 50~2000g, increasing by 5g.

③Dart head radius: Method A, (19±1)mm; Method B, (25±1)mm.

④Sample fixture: outer diameter 150mm, inner diameter 125mm.

⑤Impact height: 1500mm.

⑥Impact energy: 30J.

(3) Test method

The test was carried out in accordance with the national standard GB 9639 "Plastic Film and Sheet Impact Resistance Test Method Free Falling Dart Method". The test method is divided into two methods, A and B. Method A is suitable for materials with an impact damage mass of 50~200g, and the diameter of the dart head used is (38±1)mm. Method B is suitable for materials with an impact damage mass of 300 to 2000 g, and the diameter of the dart head used is (50±1) mm.

When preparing samples, cut out at least 30 plastic films whose length and width are greater than 153 mm, or thin slices whose thickness is less than 1 mm. Specimens shall be free of bubbles, creases or other obvious defects. All samples should be conditioned for at least 8 hours in a standard environment and tested in the same environment.

The specific test steps are as follows.

① Fasten the sample between the ring fixtures, add appropriate weights, and lift the falling dart to the specified height. The method A is (0.66±0.01)m, and the method B is (1.5±0.01)m. The falling dart is then released so that it impacts the specimen in free fall. If the sample does not break through, the falling dart should be stopped in time to avoid secondary impact.

② After impacting 20 samples, check the damage rate of the samples. If it reaches 50%, the test is over. If it is less than 50%, the quality of the falling dart should be changed and the test should be repeated.

③Using the mass of the falling dart when the sample is damaged by 50% as the damaged mass of the impact resistance of the film, and calculate the impact strength.

- 1Application of Pendulum Impact Instrument in Encasement Aluminum Plastic Paper Composite

- 2How to Evaluate Mechanical Properties of Cigarette Pack Aluminized Paper with Pendulum Impact Meter

- 3Application of Pendulum Impact Instrument in Nylon Membrane

- 4Sheet for Pendulum Impact Meter Application

- 5What are the specific applications of pendulum Impact Meter in Plastic film?

- 6What is impact testing?

- 7What properties of liquid unsaturated polyester resin for buttons are necessary? What are the indicators?

- 8What properties of phenolic resin anti-rust coatings must be inspected? What are the indicators?

- 9What performance subjects should be tested for amino alkyd resin coatings? How to judge the results?