According to the standard, what are the properties of inorganic phosphate solvent-resistant anti-corrosion coatings to be tested?

Inorganic phosphate solvent-resistant anti-corrosion coatings are widely used in solvent storage tanks, cabin interior coatings and surface anti-corrosion coatings of steel products, and can also be used for high-temperature resistant coatings. Today we will introduce the regulations of HG/T 4846-2015 on inorganic phosphate solvent-resistant anti-corrosion coatings.

Item detection

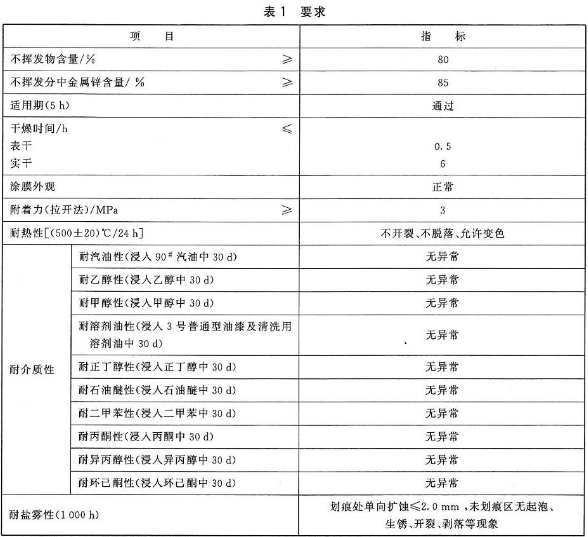

1. Non-volatile matter content: if the sample is ≥80%, it is regarded as up to standard.

2. Metal zinc content in non-volatile matter: if the sample is ≥85%, it is regarded as up to standard.

3. Suitable period: visually observe after placing for 5 hours, if the coating film is uniform, without sagging, blooming, cracks, shrinkage cavities, particles and other paint film abnormalities, it can be rated as "pass".

4. Drying time: If surface dry ≤ 0.5h, hard dry ≤ 6h, it is considered up to standard.

5. Appearance of coating film: Observe the sample under scattered sunlight. If the coating film is uniform without sagging, blooming, cracks, shrinkage cavities, particles, etc., it is rated as "normal".

6. Adhesion: It is detected by the pull-off method. If the sample parameters are ≥3MPa, it is regarded as up to standard.

7. Heat resistance: place it at a temperature of 500±20°C for 24 hours, and observe it visually after the end. If the coating film does not crack, fall off, or allow discoloration, it is considered up to the standard.

8. Medium resistance

a. Gasoline resistance: Immerse the sample in No. 90 gasoline for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels have no coating film abnormalities such as blistering, cracking, and peeling, it will be rated as "no abnormal".

b. Ethanol resistance: soak the sample in ethanol for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not have any abnormalities in the coating film such as blistering, cracking, and peeling, it will be rated as "no abnormality" .

c. Methanol resistance: Immerse the sample in methanol for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels have no coating film abnormalities such as blistering, cracking, and peeling, it will be rated as "no abnormality" .

d. Solvent oil resistance: soak the sample in No. 3 ordinary paint and solvent oil for cleaning for 30 days, take it out and dry it for observation. If there are no blisters, cracks, peeling and other coating diseases on 2 of the 3 test panels If there is no phenomenon, it is rated as "no abnormality".

e. Resistance to n-butanol: Immerse the sample in n-butanol for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any pathological phenomena such as blistering, cracking, and peeling of the coating film, it is rated as "No abnormality".

f. Petroleum ether resistance: Immerse the sample in petroleum ether for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels have no coating film abnormalities such as blistering, cracking, and peeling, it will be rated as "no abnormal".

g. Xylene resistance: Immerse the sample in xylene for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any pathological phenomena such as blistering, cracking, and peeling of the coating film, it will be rated as "no abnormal".

h. Acetone resistance: Immerse the sample in acetone for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels have no coating film abnormalities such as blistering, cracking, and peeling, it is rated as "no abnormality" .

i. Resistance to isopropanol: Soak the sample in isopropanol for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any abnormalities in the coating film such as blistering, cracking, and peeling, then evaluate to "no exception".

j. Cyclohexanone resistance: Immerse the sample in cyclohexanone for 30 days, take it out and wipe it dry for observation. If 2 of the 3 test panels do not show any pathological phenomena such as blistering, cracking, and peeling of the coating film, it is rated as "No abnormality".

9. Salt spray resistance: test by drawing a scratch parallel to the long side of the test plate. If there are no paint film abnormalities such as blistering, rusting, cracking and peeling, it is rated as "no abnormality".

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Basic Principle and Application Analysis of Paints drying time Tester

- 7Waterborne architectural coatings detection method

- 8Automatic scratch test to evaluate film strength, hardness, adhesion

- 9Comparison of film adhesion determination methods

-

-

-

-

-

-

JINGKELIAN QNF Backtack Tester 3 pcs$ 190.00