How to prepare resin anti-corrosion coating samples? What are the requirements?

Perchlorethylene resin anti-corrosion coatings are mainly used for anti-corrosion protection of various chemical equipment and concrete structure surfaces. Today we will introduce the provisions of GB/T 25258-2010 on the preparation of samples for perchlorethylene resin anticorrosive coatings.

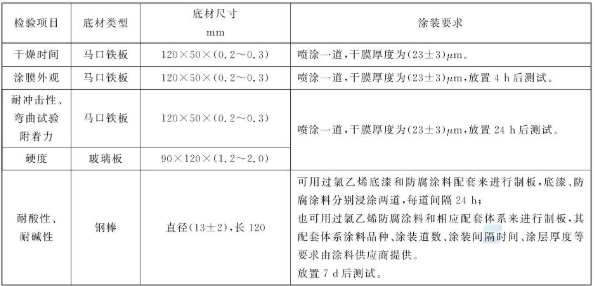

Item detection

1. Drying time: Choose a 120X50X(0.2~0.3)mm tin plate, spray one coat, and if the thickness of the film is (23±3)μm, it is considered to be up to standard.

2. Appearance of the coating film: select a 120X50X(0.2~0.3)mm tin plate, spray one coat, and the film thickness is (23±3)μm, which is considered to be up to standard. The test can be continued after standing for 4 hours.

3. Impact resistance, bending test, adhesion: select 120X50X(0.2~0.3)mm tinplate, spray one coat and place it for 4 hours, if the thickness of the film is (23±3)μm, it is considered to be up to standard. The test can be continued after 24 hours of storage.

4. Hardness: Choose a glass plate of 90X1200X(1.2~2.0)mm, spray it once and place it for 4 hours, if the thickness of the film is (23±3)μm, it is considered to be up to standard. The test can be continued after 24 hours of storage.

5. Acid resistance and alkali resistance: use a steel rod with a length of 120 and a diameter of (13±2) mm for testing.

The board can be made with perchlorethylene primer and anti-corrosion coating. First, dip-coat the primer and anti-corrosion coating twice, each time at an interval of 24 hours; perchlorethylene anti-corrosion coating and corresponding supporting systems can also be used to make boards. The paint variety, number of coats, interval time between coats and coat thickness of the supporting system shall be provided by the paint supplier. Test after 7d storage.

- 1Principle, application and selection of vertical Electric Forced Air Drying Oven

- 2Principle, application and selection of pigment Drying Oven

- 3Principle, application and selection of electric heating air Drying Oven

- 4Principle, application and selection of vacuum electric Drying Oven

- 5Principle, application and selection of nitro paint Drying Oven

- 6Principle, application and selection of industrial hot air circulation Drying Oven

- 7Principle, application and selection of small Drying Oven

- 8Principle, function and application of thermostatic Drying Oven

- 9Application of Pendulum Impact Instrument in Encasement Aluminum Plastic Paper Composite

-

-

TRUIT TR 5214 Bending Tester$ 439.00

-

-

-

-