What are the test subjects for perchlorovinyl resin anti-corrosion coatings?

In addition to superior waterproof and anti-corrosion properties, perchlorethylene coatings also have excellent weather resistance, acid resistance and deformation resistance. Today we will introduce what subjects need to be tested for perchlorethylene resin anti-corrosion coatings under GB/T 25258-2010.

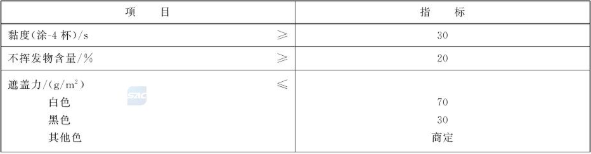

Item detection

1. Viscosity: Use Tu-4 cup to test, if the outflow time is ≥ 30s, it is considered to be up to standard.

2. Non-volatile matter content: If the non-volatile matter content of the sample is ≥ 20%, it is regarded as up to standard.

3. Covering power: white covering power ≤70g/m², black covering power ≤30g/m², it is regarded as up to standard.

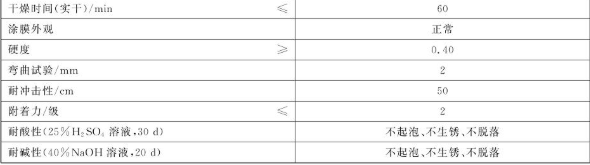

4. Drying time: ≤60min for hard drying.

5. Appearance of coating film: Use visual inspection method to observe whether there are orange peel, wrinkle, stain, particle, shrinkage cavity and other phenomena on the surface of the sample under natural sunlight. If there is no phenomenon, it can be evaluated as "normal".

6. The hardness must be ≥0.40 to be considered up to standard.

7. Bending test: If the result is within 2mm, it is considered up to standard.

8. Impact resistance: If the result is 50cm, it is considered up to standard.

9. Adhesion should be less than or equal to level 2

10. Acid resistance: immerse 3 steel rods in 25% H2SO4 solution for 30d. Among them, at least 2 steel rods must have no blistering, rusting, peeling off and other coating film pathological phenomena, and then they can be regarded as up to the standard.

11. Alkali resistance: immerse 3 steel rods in 40% NaOH solution for 20d. Among them, at least 2 steel rods must have no blistering, rusting, peeling off and other coating film pathological phenomena, and then they can be regarded as up to the standard.

- 1Principle, application and selection of vertical Electric Forced Air Drying Oven

- 2Principle, application and selection of pigment Drying Oven

- 3Principle, application and selection of electric heating air Drying Oven

- 4Principle, application and selection of vacuum electric Drying Oven

- 5Principle, application and selection of nitro paint Drying Oven

- 6Principle, application and selection of industrial hot air circulation Drying Oven

- 7Principle, application and selection of small Drying Oven

- 8Principle, function and application of thermostatic Drying Oven

- 9Tu-4 cup viscosity test steps, instruments and usage

-

-

-

TRUIT TR 5214 Bending Tester$ 439.00

-

-

-