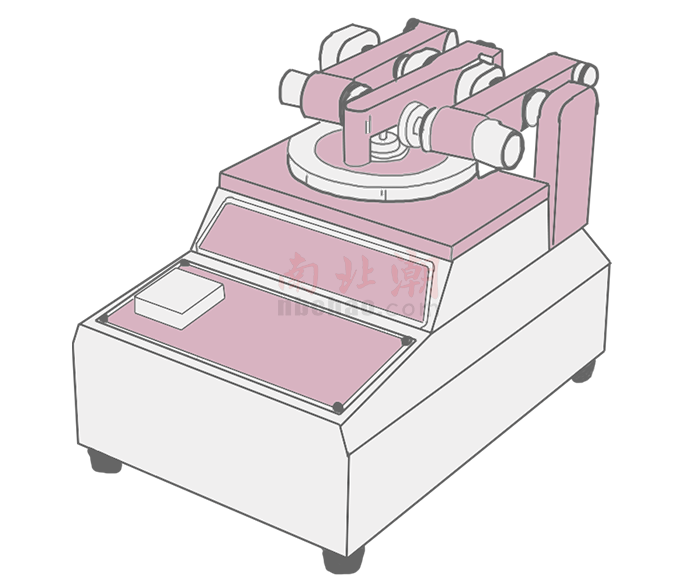

Determination of Wear Resistance of Ink Film by Abrasion Meter

The wear resistance test of ink refers to the resistance of ink film layer to mechanical action such as friction. This is mainly related to the comprehensive manifestation of the adhesion, hardness and cohesion of the ink film layer. Of course, the substrate material (such as film, paper, fabric, metal, etc.), the surface treatment of the film layer and other factors are also closely related. The friction resistance of the ink can be measured by the rubber grinding wheel method (that is, what we often call the taber abrasion Tester).

This kind of abrasIon Meter drives the grinding wheel through the motor, and the sample is fully rubbed through the continuous rotation of the grinding wheel, and then records the number of circles through the counter. The operation method is relatively simple. Fix the sample on the working plate of the abrasIon Meter, increase or decrease the pressure weight according to the demand, fix the rubber grinding wheel, put down the dust suction part, and adjust the speed. The sample of the ink can be ground 50 times first, and G1 can be weighed by a percent balance, and then G2 can be weighed on the balance again after re-grinding to the specified speed, which is expressed by the weight loss of the ink film layer. The formula is as follows:

Friction weight loss G=G1-G2

The greater the weight loss, the worse the abrasion resistance of the ink.

This kind of wear meter is widely used, so I won't introduce it here.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Application of shakeout Tester in organic polymer film abrasion resistance testing

- 6Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 7Optical inspection device Anti-reflection film adhesion Measuring method

- 8Automatic scratch test to evaluate film strength, hardness, adhesion

- 9Comparison of film adhesion determination methods