Test method for tape adhesion

The tape adhesion test method uses pressure sensitive tape to determine the adhesion quality of a coating. In order for corrosion resistant coatings to function properly, they need to adhere to the surface they are applied to, and tape adhesion testing can determine whether a coating is properly adhering to its substrate.

ASTM D3359 is known as the Standard Test Method for Measuring Adhesion by Tape Test.

Tape Adhesion Test

There are two methods of tape adhesion testing, which can be performed in the laboratory or on the job site.

The X-cut tape test is used on the job site. Using a razor blade, knife, or other sharp cutting implement, make two cuts from the coating all the way to the substrate, forming an "X" with a 30 to 45-degree angle between the legs. The tape is placed in the center of the "X" and removed quickly. Then check the area to see if any coating has been removed.

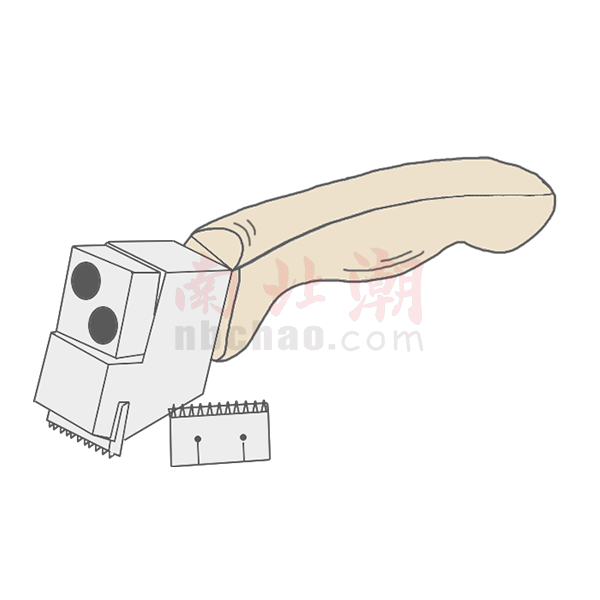

Cross-hatch tape testing is performed in the laboratory on coatings less than 125 microns thick. It uses a cross-hatch pattern, which is created using a cutting guide or a special cross-hatch cutter with preset blades, to help ensure that the cuts are parallel to each other and properly spaced. After the tape is applied and peeled off, inspect the area and rate it.

After any failed test, it is important to document whether the adhesion failure was adhesion (at the coating/substrate interface) or cohesion (within the coating film or substrate).

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof