Structure Diagram Sharing of Pull-off Adhesion Tester | Test Methods, Steps and Applicable Standards

The pull-off method is a test method for evaluating adhesion. Applicable standards are ISO4624:2002, GB 5210-85, ASTM D 4514. There are two types of pull-off testing apparatus, mechanical and hydraulic/pneumatic.

Two types of adhesives are used in adhesion pull-off testing: epoxy adhesives and fast-drying cyanoacrylate adhesives. Epoxy adhesives can be tested after 24 hours at room temperature, while quick-drying cyanoacrylate adhesives can reach test strength after 15 minutes at room temperature, and it is recommended to test after 2 hours.

The scotch tape is mainly used to fix the aluminum alloy cylinder that has just been stuck to prevent the cylinder from deviating from the original bonding position due to the adhesive not being cured to a certain degree of fastness.

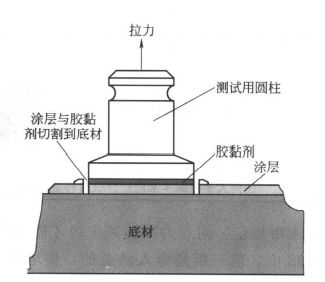

The cutter is used to cut the coating and adhesive around the aluminum alloy cylinder to the substrate to prevent the surrounding coating from affecting the precision of the adhesion. Cutting can be omitted if the dry film thickness is less than 150jm. Test the structure with the pull-off adhesion test.

The structure is as follows:

-

-

-

-

-

KOSON KS-T smart Adhesion Tester$ 1078.00

-

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof