Adhesion Factors of Paints and Coatings & Test Methods

What is Coating Adhesion?

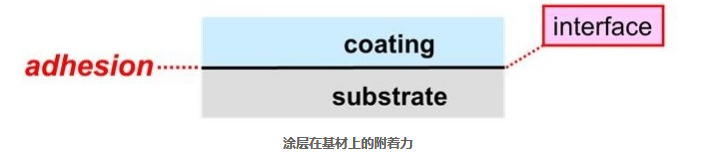

Coating adhesion refers to the firm bond between the coating and the material substrate.

Adhesion is one of the fundamental properties in the paint and coatings industry, ensuring that paints (or paint films) adhere to surfaces for a long time, especially under aggressive conditions. The nature of adhesion is directly related to the durability and quality of the coating.

An important requirement for most coatings and inks is that they form a strong bond and adhere firmly to the substrate for a long time after curing and film formation is complete. The bond strength between a coating and a substrate depends on two properties of the material, including:

Adhesion – the bond strength of the adhesive to the surface of the substrate

Cohesion – the strength of the bond between the binder particles

* Film formation plays a key role in adhesion. After curing, several factors such as shrinkage and pressure affect film formation.

Key factors controlling the adhesion of coatings and inks to substrates include:

Substrate-coating interface

Composition of paints and inks

Film formation (need to make the interface as strong as possible)

Binders or resins in coating formulations are non-volatile film-forming components. It ensures adhesion to the substrate and cohesion within the paint film. The type of binder affects film formation, film strength and other properties (physical or chemical).

Adhesion failure in coating

With strong adhesion, the coating prevents surface damage. A notable example is the use of coatings in corrosion protection.

However, coating adhesion may be adversely affected after prolonged exposure to external factors such as water, humidity and UV radiation. In addition, poor choice of surface coating, incompatibility of the coating with the surface, and insufficient surface preparation can lead to coating adhesion failure

Factors Affecting Adhesion

There are several factors that can cause the bond between the paint film/coating and the substrate to fail, as listed below.

Poor cleaning of the substrate prevents the coating from adhering to the substrate surface when the soil is not completely removed from the substrate.

Surface contours, such as smooth surfaces that do not hold coatings well.

Improper wetting of the coating on the substrate can affect surface adhesion and proper adhesion.

Insufficient cross-linking or under-cured/over-cured coating results in poor adhesion of the coating to the substrate surface.

External environmental factors such as water, humidity, ultraviolet radiation, etc.

These factors can lead to a variety of surface defects that can lead to bond failure. Some common surface defects are:

Blistering – Occurs when a coated object is immersed in water. Blisters are dome-shaped imperfections that appear on surfaces. Blistering is caused by water-soluble materials in or under the coating, rapid drying of the coating, or chemical exposure.

Peeling – A decrease in the bond strength of the paint film due to contamination or incompatibility of the coating.

Flaking – Causes the paint to separate from the substrate.

Undercut – involves corrosion buildup under the coating.

Test Methods for Evaluating Adhesion

Several methods can be used to determine how well a coating will bond to the substrate - making the coating perform well. When implementing any test method, it is important to consider whether the adhesive failure is cohesive (failure at the coating/substrate interface) or cohesive (failure within the coating film or substrate).

The main methods used to test paint adhesion include:

cross-cut inspection

scratch test

Pull test

#1. Cross-cut method

ASTM D3359 - Standard Test Method for Evaluating Adhesion by Tape Test

These test methods cover procedures for evaluating the adhesion of coated films to metal substrates by applying and removing pressure-sensitive adhesive tape over cuts in the film.

This test method is similar in content to ISO 2409 (but not technically equivalent).

#2. Circle method

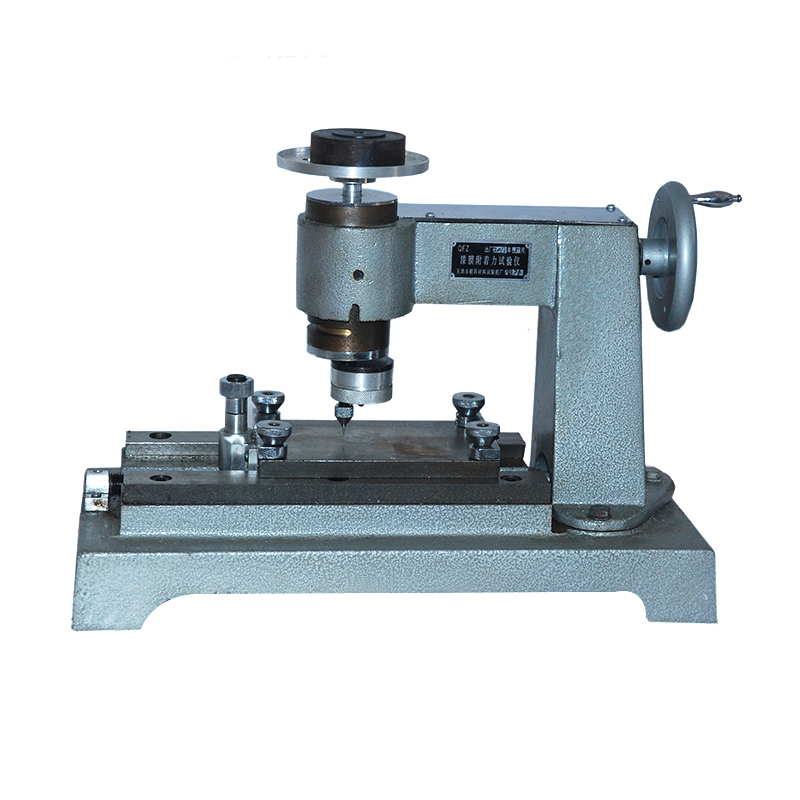

ASTM D2197 - Standard Test Method for Adhesion of Bonded Organic Coatings by Scratch Adhesion

This test method determines the adhesion of organic coatings, such as paints, varnishes, and varnishes, when applied to smooth and flat (flat) panel surfaces.

The material to be tested is applied to a smooth substrate in a uniform thickness. After drying, adhesion is determined by pushing the panel under a circular stylus or ring, which is loaded in increasing amounts until the coating is removed from the substrate surface.

#3. Pull test

ASTM D4541 - Standard Test Method for Pull-off Strength of Coatings Using a Portable Adhesion Tester

This test method covers procedures for evaluating the pull-out strength (often called adhesion) of coatings on rigid substrates such as metal, concrete, or wood.

This method evaluates the adhesion of one or more coatings on a smooth surface by applying the tensile stress of the cart to the surface (instead of the shear stress measured in the previous two tests). The load is slowly increased until the cart and adhesive layer are removed. It is equivalent to the ISO 4624 standard.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof