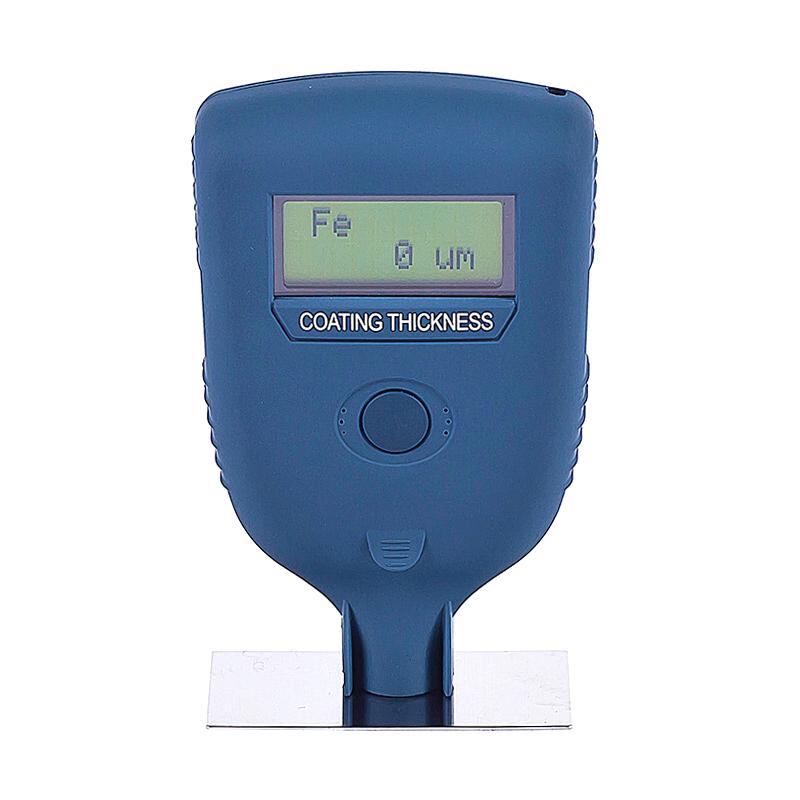

LEEB leeb252 Coating Thickness Gauge magnetic Induction/eddy Current dual-use automatic identification substrate

-

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE -

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 510.00SE

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 510.00SE -

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE -

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 389.00SE

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 389.00SE -

LANDTEK CM8855 coating Film Thickness Gauge Integrated F magnetic Induction /NF eddy current statistical function$ 493.00SE

LANDTEK CM8855 coating Film Thickness Gauge Integrated F magnetic Induction /NF eddy current statistical function$ 493.00SE

Leeb leeb252 Coating Thickness GaugeSPEC

Leeb leeb252 Coating Thickness GaugeDetails

Leeb leeb252 Coating Thickness GaugePacking list

- SKU

- NB001251

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1250μm

- margin of error

- ±3%

- resolution

- 1μm

- Minimum measurement surface

- Φ10mm

- minimum radius of curvature

- Convex 1.5mm; Concave 20mm

- thinnest matrix

- 0.5mm

- probe

- F1/N1 integrated probe

- icon function

- none

- Power Supply

- 4 * AAA 1.5V alkaline battery

- Calibrated Certificate

- none

- system language

- Chinese

- Display screen

- LCD screen

- companion software

- none

- Weight

- 120g

- Dimension

- 150*55.5*23mm

- Operating temperature

- 0~40℃

- Relative Humidity

- 20~90%RH

Overview

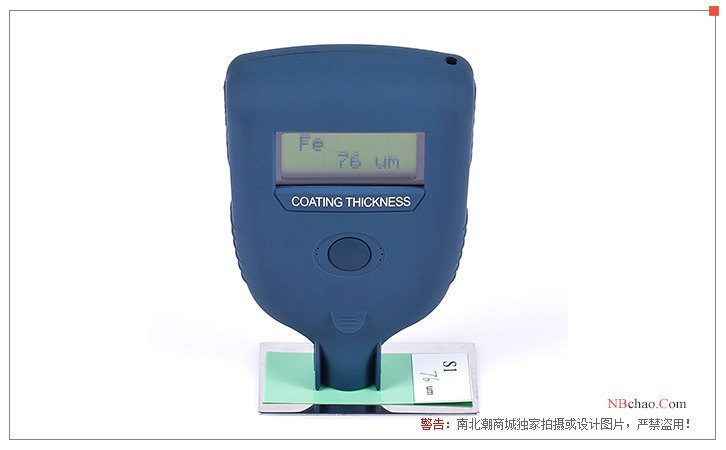

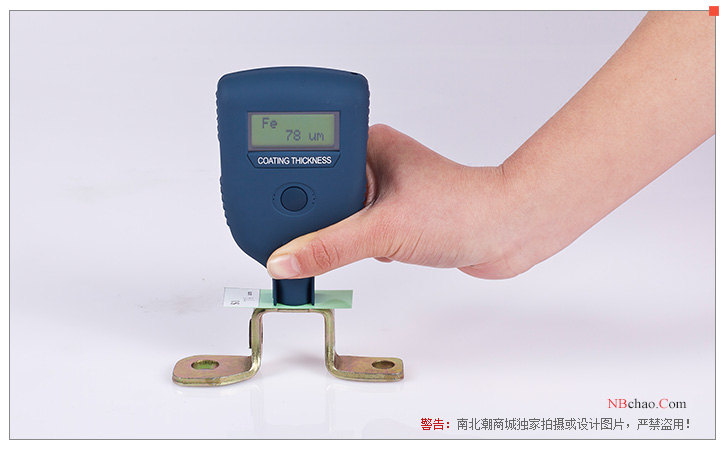

The LEEB252 coating Thickness Gauge is a dual-purpose Thickness Gauge with built-in probe integrated structure, the probe can automatically identify magnetic metal substrates and non-magnetic metal substrates, accurately measure the thickness of the cladding, the measurement display accuracy is 1 micron, one-button operation, simple and convenient operation.

The minimum radius of curvature measured by leeb252 coating Thickness Gauge is convex 1.5, concave 20mm, and the minimum area diameter is Φ10mm, which is suitable for operation in the environment of 0~40 degrees Celsius temperature and 20%~90% humidity.

Features

1. Built-in probe type, integrated structure design, small size, easy to carry.

2. One-button operation, one-handed operation can be carried out, and the operation is simple.

3. Magnetic induction and eddy current dual-purpose Thickness Gauge can automatically identify different substrates.

4. Liquid crystal digital display, intuitive and clear reading.

Product Applications

LEEB252 Coating Thickness GaugeNon-destructive testingThe thickness of the non-conductive insulating covering on a non-magnetic metal substrate (e.g., aluminum,Rubber, plastic, paint,copper, zinc, oxide film, etc.) andThe thickness of the non-magnetic overlay on a magnetic metal substrate (e.g., aluminum on steel alloys and hard magnetic steels,Copper, zinc, tin,chrome, rubber, paint, etc.).

Application

LEEB252 Coating Thickness Gauge is suitable for:Aviation, Chemical,Shipbuilding, light industry, commodity inspection,CarElectroplating, anti-corrosion, aerospace and other testing fields can be used in the laboratory or construction site.

Actual picture of the product

- 1Principle and Application Analysis of Coating Thickness Gauge

- 2Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 1ISO 《Non-magnetic metallic coatings on metallic and non-metallic basis materials — Measurement of coating thickness — Phase-sensitive eddycurrent method》

- 2GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 3QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 4GB/T 11374-2012《Thermal spraying coating - Nondestructive methods for measurement of thickness》

- 5GB/T 4957-2003《Non-conductive coatings on non-magnetic basis metals--Measurement of coating thickness--Eddy current》

leeb252

leeb252