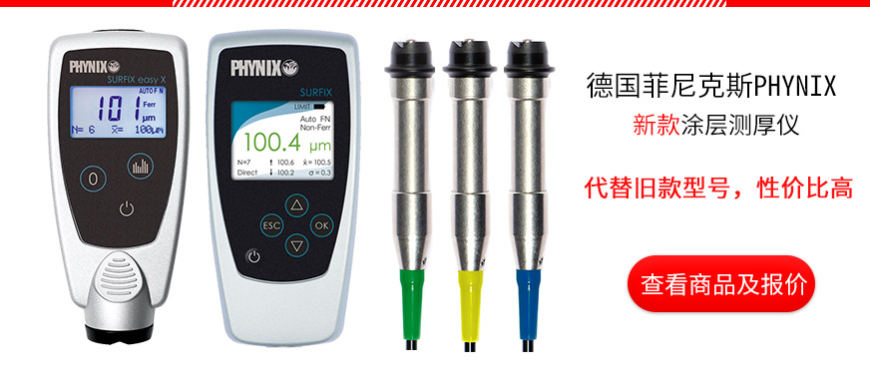

Germany PHYNIX Surfix ® easy X E-FN easy-to-use external probe dual-use type Film thickness meter

PHYNIX Surfix® easy X E-FN Easy-to-use external probe dual-use film thickness MeterSPEC

PHYNIX Surfix® easy X E-FN Easy-to-use external probe dual-use film thickness MeterDetails

PHYNIX Surfix® easy X E-FN Easy-to-use external probe dual-use film thickness MeterPacking list

- SKU

- NB012552

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- F:0~3500μm;N:0~3000μm

- margin of error

- ±2%

- resolution

- 1μm|2μm|5μm

- Minimum measurement surface

- 10*10mm

- Minimum radius of curvature

- Convex 5mm; Concave 50mm

- thinnest substrate

- 0.5mm(F);50μm(N)

- probe

- External probe

- Probe size

- Φ24*45mm

- Calibrated Certificate

- Manufacturer Certificate

- Calibrated mode

- Factory calibrated, zero calibrated

- Unit display

- µm/mils

- statistical function

- MAX Maximum, MIN Minimum, Average, Standard deviation

- Power Supply

- AAA battery × 2

- Standards

- DIN,ISO,ASTM,BS

- Display screen

- Backlight, 4 alphanumeric, height 8mm

- Operating temperature

- 0℃~50℃

- Protection level

- IP52

- Weight

- 140G with battery

- Dimension

- 110*50*25mm

- Probe contact temperature

- -15~60℃

The Surfix® easy X-series Film Thickness Gauges are designed for everyday use and demanding laboratory measurements. The Surfix®easy X series is a new Film Thickness Gauge available in 4 versions:

Surfix® easy X I-FN: built-in probe, magnetic induction + eddy current

Surfix® easy X I-F: built-in probe, magnetic sensing

Surfix® easy X E-FN: external probe, magnetic induction + eddy current

Surfix® easy X E-F: external probe, magnetic sensing

The specific differences of the Surfix® easy X series Film Thickness Gauges can be found in the table below:

| easy X series | Surfix® easy X I-FN / I-F | Surfix® easy X E-FN / E-F |

| Built-in probes | ||

| Minimum convex radius of curvature | ||

Application

Paints, coatings, automobile manufacturing, ships, steel construction, etc.

merit

1. No calibration, you can measure when you turn on the machine;

2. Backlight display, easy to measure in dark environment;

3. Precise and precise measurements can be made on flat, rough and curved surfaces

4. Automatic identification of substrate measurement of iron/steel and non-ferrous metals

5. Online statistics (quantity, mean, standard deviation, minimum, maximum)

6. Large contact area, more convenient positioning

7. Manufacturer's test certificate

Surfix® easy X E-FN

Surfix® easy X E-FN