TIMES TT320 High Temperature Ultrasonic Thickness Gauge Temperature up to 300 ℃

TIMES TT320 Ultrasonic Thickness GaugeSPEC

TIMES TT320 Ultrasonic Thickness GaugeDetails

TIMES TT320 Ultrasonic Thickness GaugePacking list

- SKU

- NB013263

- Measurement range

- 0.75 to 300mm (steel, determined by the probe), 4.0 to 80mm (high temperature)

- Probe diameter

- Ф10mm

- Probe contact temperature

- -10~300℃

- Lower limit of pipe measurement

- < unk > 20mm3.0mm (5P < unk > 10 probe, steel)

- measurement error

- ±(1%H+0.1)mm

- Display resolution

- 0.1mm

- Zero proofreading

- automatic

- Storage Capacity

- 5 groups of 500 thickness values, 5 Speed of sound values

- Speed of sound

- 1000~9999m/s

- Display

- Four large screen backlit digital display, adjustable contrast ratio

- Power Supply

- AA type alkaline 1.5V battery (2 pcs)

- Operating Time

- 100h

- Application

- Petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace, etc

- shutdown mode

- Manual shutdown or automatic shutdown (after three minutes of no operation)

- Speed of sound adjustment

- OK

Introduction

TT320 ultrasonic Thickness Gauge is based on the principle of ultrasonic pulse reflection to measure the thickness, when the ultrasonic pulse emitted by the probe reaches the material interface through the measured object, the pulse is reflected back to the probe, and the thickness of the measured material is determined by accurately measuring the time of ultrasonic wave propagation in the material. This principle can be used to measure all kinds of materials that can make ultrasonic waves propagate within it at a constant speed, such as metals, plastics, ceramics, and glass. Accurate measurements can be made of a wide range of plates and machined parts, and an important aspect is the monitoring of various pipes and pressure vessels in production plants to monitor their degree of thinning after corrosion during use.

Features

1. It is equipped with coupling prompt and low Voltage prompt;

2. Shutdown mode: manual and automatic shutdown and other functions (no operation after three minutes);

3. Minimum value capture: You can choose to display the current thickness value or the minimum thickness value

4. Data transmission: RS232 interface.

5. Data storage: 500 measured values and 5 sound velocity values can be stored

6. Limit alarm: the limit can be set, and the measured value outside the limit can automatically beep the alarm

7. Adjustable sound velocity: the sound velocity can be measured by using a test block of known thickness;

8. Gain setting: It has the function of high-low gain setting

9. Metric and British conversion: mm or inch can be selected

10. Backlight display: suitable for measurement in poor lighting environments.

Product Applications

TT320/AUltrasonic Thickness GaugeIt is widely used in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields.

TT320/AUltrasonic Thickness Gauges add a number of features such as gain setting, limit alarms, data transmission, and more.

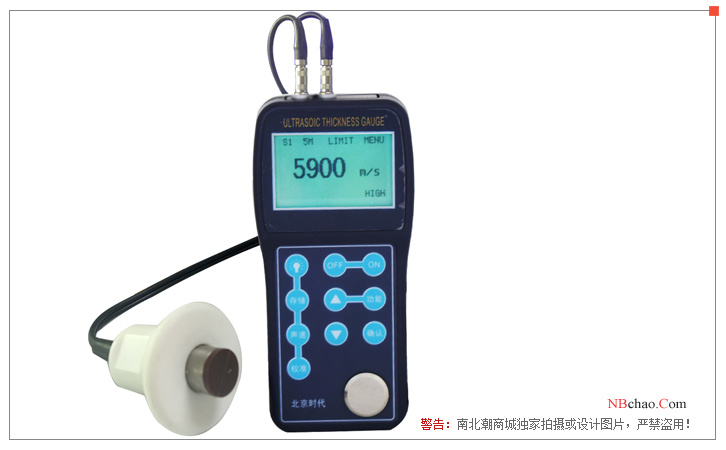

Product Display

- 1ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 2GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 3JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 4ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》

TT320

TT320