Ultrasonic Thickness Gauge DC-4000, automatic and manual measurement

SE-

Ultrasonic Film thickness Measurement Instrument DC-2020C Deguang Electronics, Film thickness measurement of metal, plate, pipeline, etc$ 1061.00SE

Ultrasonic Film thickness Measurement Instrument DC-2020C Deguang Electronics, Film thickness measurement of metal, plate, pipeline, etc$ 1061.00SE -

LANDTEK TM-1240 Ultrasonic Thickness Gauge$ 322.00SE

LANDTEK TM-1240 Ultrasonic Thickness Gauge$ 322.00SE -

Metal Ultrasonic Film thickness meter DC-3020C Deguang Electronic Glass, steel pipe and other Film thickness measurement$ 1562.00SE

Metal Ultrasonic Film thickness meter DC-3020C Deguang Electronic Glass, steel pipe and other Film thickness measurement$ 1562.00SE -

Steel plate Ultrasonic Thickness Gauge DC-3000C, penetration coating measurement material Film thickness$ 1312.00SE

Steel plate Ultrasonic Thickness Gauge DC-3000C, penetration coating measurement material Film thickness$ 1312.00SE -

Ultrasonic wall Thickness Gauge DC-2030C Deguang electronic measurement of cast iron and other Film thickness$ 936.00SE

Ultrasonic wall Thickness Gauge DC-2030C Deguang electronic measurement of cast iron and other Film thickness$ 936.00SE

DGC DC-4000 Thickness GaugeSPEC

DGC DC-4000 Thickness GaugeDetails

DGC DC-4000 Thickness GaugePacking list

- SKU

- NB001340

- Measuring range

- T~E:1.4~200mm;E~E:3.0~25mm

- Probe frequency

- 5MHz

- Probe style

- Split probe (D5301 penetrating coating probe)

- Probe contact temperature

- <60℃

- Display resolution

- ± 0.1mm (measurement greater than 100mm), ± 0.01mm (measurement less than 100mm)

- unit system

- mm/inch

- Measurement mode

- Standard, MIN Minimum, Difference Value, Average, Upper and Lower Limit Settings

- Sound speed range

- 1000~9999m/s

- Display

- 320X240 four-bit color TFT dot matrix liquid crystal display

- Operating language

- Chinese

- Data Interface

- USB

- Application software

- without

- Operating Temperature

- -20~50℃

- Storage temperature

- -20~50℃

- Power

- 2 * 7 AAA battery

- Operating Time

- 24h

- Host size

- 133*75*29mm

- Weight

- 260G (including battery)

- Measurement speed

- Ordinary measurement 2 times/second; high-speed measurement 10 times/second

- Shutdown method

- 1 minute, 3 minutes, 5 minutes automatic shutdown optional

- Optional probe

- D5008、D5113、D7006、D7004、D2012

Introduction

Different from DC2000 and DC3000 series, Deguang Electronics DC-4000 High Precision Ultrasonic Thickness Gauge is an A- and B-scan ultrasonic Thickness Gauge with color screen automatic measurement, and has two modes of manual measurement and automatic measurement. DC-4000 High-precision Ultrasonic Thickness Gauge has a blue shell, a large LCD color display, and a calibration test block under the operation panel, which can calibrate the Thickness Gauge at any time to achieve accurate measurement results.

DC-4000 high-precision ultrasonic Thickness Gauge has a variety of measurement methods: standard measurement, minimum value measurement, differential value measurement, average value measurement, upper and lower limit setting measurement and other measurement methods. Users can choose according to their actual needs. The ultrasonic Thickness Gauge has high measurement accuracy, reliability and stability, and is easy to carry.

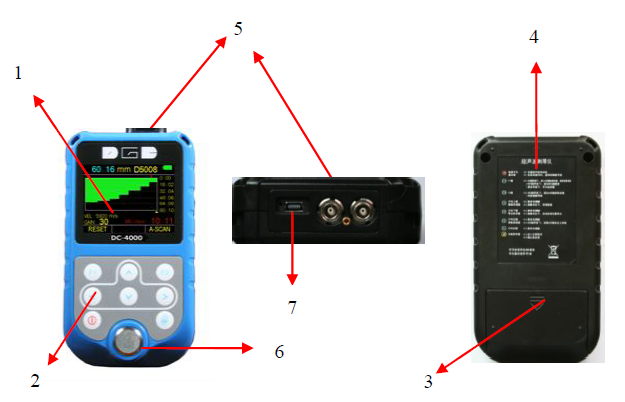

product structure

1. Appearance structure

The structure of DC-4000 high-precision ultrasonic Thickness Gauge includes: ①LCD panel ②Keyboard ③Battery compartment (back)④Instrument label (back)⑤Probe socket, identification pin ⑥Calibration test block ⑦USB data transmission interface.

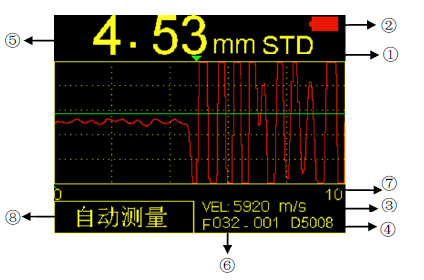

2. Display data description

① Measurement symbol

② Display of full battery and low Voltage

③ Speed of sound display

④ Probe model display

⑤ Measurement value and measurement system

⑥ F032-001 The instrument stores the current file and address

⑦ Waveform display range

⑧ Measurement mode

3. Keyboard part

The keyboard keys of DC-4000 high-precision ultrasonic Thickness Gauge are:

① Power key,

Escape key, back to the measurement interface key

②High -precision ultrasonic Thickness Gauge menu key, confirm the modification item

③ Arrow up key, store data

④ Arrow down key to automatically calibrate the zero point of the instrument

⑤ Left arrow key to read A-scan custom parameters

⑥ Direction right button

⑦F1: Enter the A-scan parameter setting, select the setting item, in the B-scan interface, reset the B-scan image, in the menu interface, return key

⑧ F2: In the A-scan interface, exit the A-scan parameter setting, switch the measurement interface between A-scan, large-screen digital display and B-scan

Features

1. The DC-4000 high-precision ultrasonic Thickness Gauge adopts a 320×240 liquid crystal display, and the display data is intuitive and clear.

2. It has a variety of measurement methods: standard measurement, minimum value measurement, differential value measurement, average value measurement, upper and lower limit setting measurement, etc.

3. Using automatic measurement of A- scan and B-scan

4. The thickness of the material can be measured by material selection and sound velocity input

5. Measurement mode: normal measurement and through coating measurement

6. Probe automatic zero calibration and probe automatic recognition

7. Gain, gate, etc. can be adjusted automatically or manually

8. A-scan, large characters or B-scan display

9. The standard configuration is 5MHz penetrating coating probe, other probes are optional

10. DC-4000 high-precision ultrasonic Thickness Gauge has a USB output interface, which can directly read data.

Pictures

- 1General method of film preparation

- 2A film of uniform thickness prepared with drawdown blades

- 3Introduction of nondestructive thickness testing principle and instrument

- 4How to choose a Thickness Gauge?

- 5National testing standards commonly used in car painting

- 6Measuring methods of coating Thickness Gauge

- 7Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 8Deguang DC-4000 Intelligent Ultrasonic Thickness Gauge Operation Instructions

- 9How to choose a suitable painting Thickness Gauge?

- 10Dry goods | Coating Thickness Gauge working principle and FAQ summary

杨琳 - 《浅谈涂层测厚仪工作原理与常见故障》

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3JB/T 11604-2013《Non-destructive testing instruments.Ultrasonic thickness gauge》

- 4ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 5GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 6JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 7ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》

DC-4000

DC-4000