LABO Labo LB-T541 Z-direction Tensile Strength Meter, Range 10~ 1000kPa

SELabo LB-T541 Z Tensile Strength TesterSPEC

Labo LB-T541 Z Tensile Strength TesterDetails

Labo LB-T541 Z Tensile Strength TesterPacking list

- SKU

- NB013519

- Force range

- 10 ~ 1000kPa

- Indication resolution

- 0.1kPa

- Error of indication

- ±1%

- Indication of variability

- ≤1%

- Test disk surface horizontal longest direction parallel error

- ≤ 0.0005mm/square millimeter

- stretching speed

- 1~220mm/min

- Adhesive pressure setting range

- (99~ 1999) N adjustable

- Pressurization time setting range

- (1~ 200) seconds adjustable

- Power

- AC220V ± 22V 50Hz 0.5A should be reliably grounded

- Dimensions

- 335*325*515mm

- Net Weight

- 33kg

- Service life of Chinese measurement and control LCD

- About 50,000 hours

Introduction

It is used to test the Z-direction tensile strength of paper and cardboard, that is, the internal bond strength of paper and cardboard. It is mainly used in multi-layer cardboard such as sand tube paper, white cardboard, box board, gray board , white cardboard, parchment paper, and coated paper. The bonding strength between layers is low or the distribution is uneven, which may cause paper and Boards have problems laying in offset presses with viscous inks. If the ply bond value is too high, it prevents the board from being cut. A high ply bond also means wasting raw materials and energy. Our The aim is to obtain a consistent strength throughout the width of the web during production, according to the specific requirements of the customer.

Features

High-precision load cell, American computer chip high-speed sampling control, stepping motor, precision ball screw drive, reasonable design and precision machining ensure the high accuracy and repeatability of the instrument. From pressing and sticking the tape, pressurizing time, to separating the sample, it is fully automatic, which is convenient and reduces human error, greatly improving the test accuracy. LCD Chinese display, friendly man-machine interface operation, with test data statistical processing function, printer printing, can be connected to the host computer through software. The test speed, bonding pressure, pressurization time, etc. can be changed and preset, which is convenient for schools, research institutes and other departments to carry out scientific experiments and analysis. The upper and lower pressure heads are easy to remove, which is convenient for cleaning the residue left by the adhesive tape during the experiment, and it is also convenient for the standard sensor to be connected for force value calibration.

Instructions for use

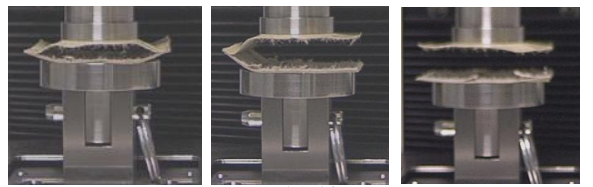

Use sampling equipment to evenly plant and cut (50×50) mm square samples from the sample, paste double-sided adhesive tape on the front and back sides of the sample, and then tear off the other two-sided adhesive tape and place the sample in the center of the lower pressure head , start the instrument, the lower indenter starts to rise, and starts to apply pressure after contacting the sample with the upper indenter, until the pressure value reaches the set value of the bonding pressure, stop, and keep this pressure until the set pressurization time, The lower indenter starts to move down for the test until the sample is separated, and the lower indenter automatically returns to the initial position after the test is completed, and the measurement result value is read.

Applicable standard

GB/T31110-2014

ISO15754

TAPPI T541

Note: Due to different production batches, the appearance may be slightly different, the actual product shall prevail, but all functions will not be affected.

- 1GB/T 28210-2024《Thermal-sensitive paper》

- 2SN/T 4706-2016《Fiberboard transport containers.Tensile test for the manufacturer's joint》

- 3QB/T 1053-2004《Paper and board-Tester of tensile properties》

- 4GB/T 28995-2022《Special paper for wood-based panels decoration》

- 5GB/T 34688-2017《Printability of digital printing paper and test methods》

- 6JJG (轻工)58.2-2000《Horizontal teasion tester for paper and Board》

- 7JJG (轻工)58.1-2000《Tension Tester for Pendulum Model》

- 8GB/T 453-2002《Peper and board--Determination of tensile properties (Constant rate loading methods)》

- 9QB/T 2693-2005《QB/T 2693-2005》

- 10GB/T 22898-2008《Paper and board - Determination of tensile properties - Constant rate of elongation method (100mm/min)》

LB-T541

LB-T541