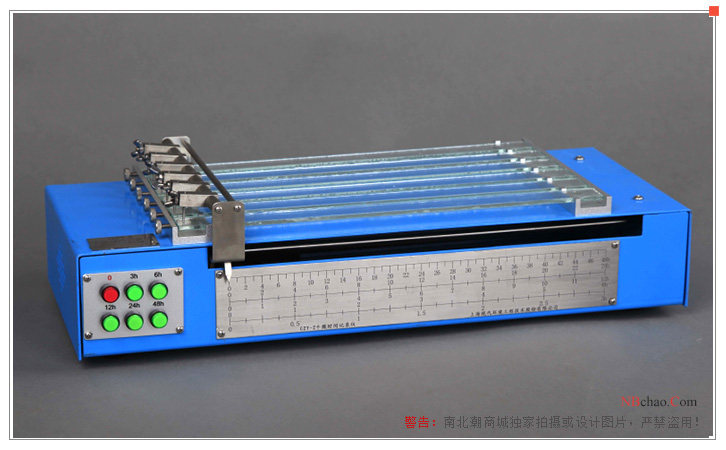

MODERNER GZY-2 Drying Time Recorder drying time up to 48 hours

Moderner GZY-2 Drying Time RecorderSPEC

Moderner GZY-2 Drying Time RecorderDetails

Moderner GZY-2 Drying Time RecorderPacking list

- SKU

- NB001456

- Number of strokes

- 6-Pin

- itinerary

- 304.8mm

- trajectory period

- 3/6/12/24/48h

- input Voltage

- 220V 50Hz

- Dimensions

- 490*220*130mm

- Machine Weight

- 8kg

- Glass size

- 23×340mm

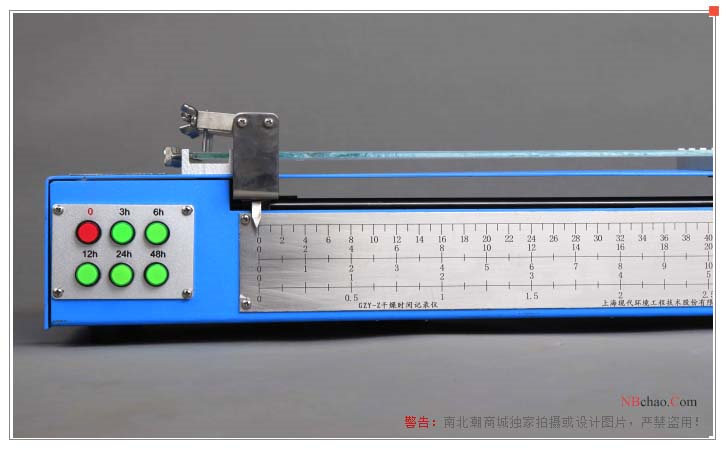

- Scribe clip

- Can hold ball or pointed scribing needles with an outer diameter of ≤ 0019 2

Instrument introduction

MODERNER GZY-2 drying time Recorder is an upgraded model of the GZY-1 model, with a longer Timer Setting, between 3 and 48 hours. The GZY-2 drying time Recorder uses a scratch needle to draw across the coating at a constant speed and slowly, and observes the scratch tracks formed on the surface of the coating film to evaluate the drying time of the coating film. The GZY-2 drying time Recorder has six scratching needles, which can detect six different products at the same time, saving costs, time and high efficiency.

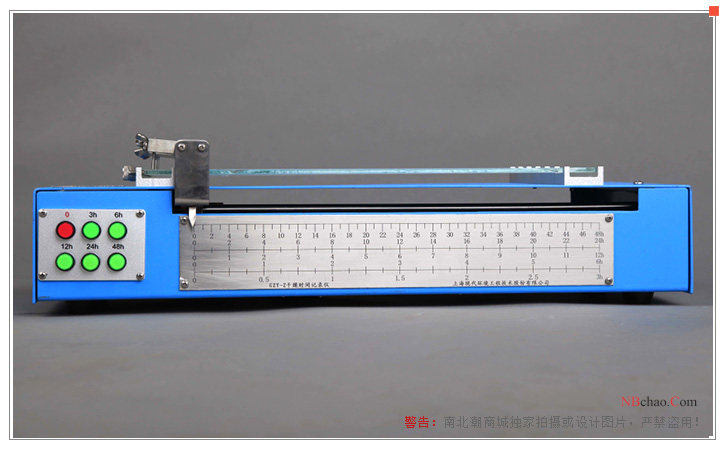

GZY-2 functional structure

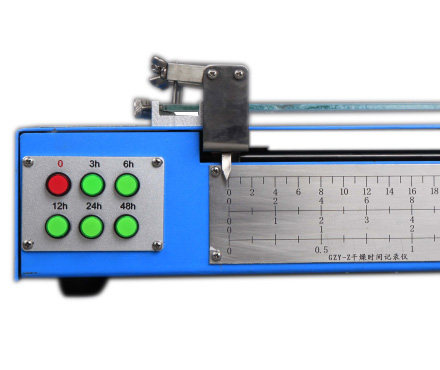

1. GZY-2 is driven by a stepper motor to provide accurate movement control.

2. There are six scribe needles installed on the slide frame. The movement of the slide frame drives the scribe needle to move on the glass sheet coated with the wet film.

3. When the stroke ends, the GZY-2 drying time Recorder will automatically stop.

4. Lift up the pressure plate on the lower rear side of the carriage to manually move the funny to reset it.

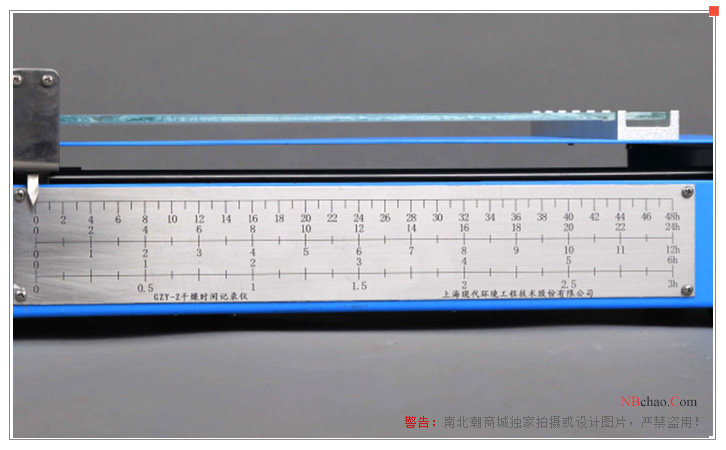

5. The front end of the GZY-2 drying time Recorder is equipped with a ruler, which can convert moving distance and moving time.

6. It has 3 to 48 hours timing and has five different moving speeds to choose from .

Actual pictures of GZY-2 drying time Recorder

How to operate the GZY-2 drying time Recorder

1. Preparation work before test:

(1) The test should be conducted under constant temperature and humidity conditions.

(2) The GZY-2 drying time Recorder should be placed on a flat table away from strong magnetic fields and strong electromagnetic pulse interference.

2. Operation method:

(1) Turn on the power and turn on the power switch at the rear of the GZY-2 drying time Recorder.

(2) If the carriage is not in the starting position on the left side, you can lift the pressure plate on the lower rear side of the carriage and manually move the carriage to reset it.

(3) Install a suitable scribing needle (ball head or pointed head) on the scribing needle clip to keep the scribing needle rod perpendicular to the glass piece.

(4) Loosen the set screw on the bracket, remove the glass piece, and prepare a wet film on the glass piece (the wet film should comply with relevant standards or meet the requirements agreed between the buyer and the seller).

(5) Put the glass piece back on the bracket and tighten the set screw at one end appropriately.

(6) Put down the needle clip so that the needle is in contact with the new coating layer.

(7) Select the appropriate speed gear, press the corresponding button, and the carriage begins to move slowly to the right. If you need to change the selection at this time, you need to press the stop button before selecting again. After the specified time, the GZY-2 drying time Recorder will automatically stop and give an alarm sound.

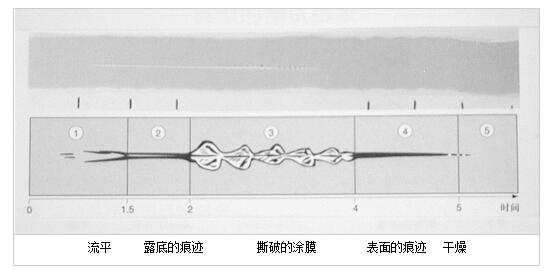

(8) Evaluate the results corresponding to each drying stage of the observed trajectory. The drying time can be converted through the scale on the edge of the GZY-2 drying time Recorder.

Note: As shown in the figure, the coating begins to dry out after 2 hours of testing (at the beginning of track â¢); by 5 hours it has dried (at the beginning of track â¤, the product disappears).

Precautions for use

1) After using it for a period of time, the screw rod and sliding rod in the GZY-2 drying time Recorder should be properly lubricated from the openings on both sides.

Optional parts

GZY-Film Applicator: wet film thickness 38μ/76μ; or wet film thickness 75μ/150μ; (wet film thickness can also be customized according to customer requirements).

GZY-coating attachment: suitable for 3Ã23Ã340 glass sheets.

GZY-2

GZY-2